klaxon can be connected via auxiliary contacts (see

the plant manual).

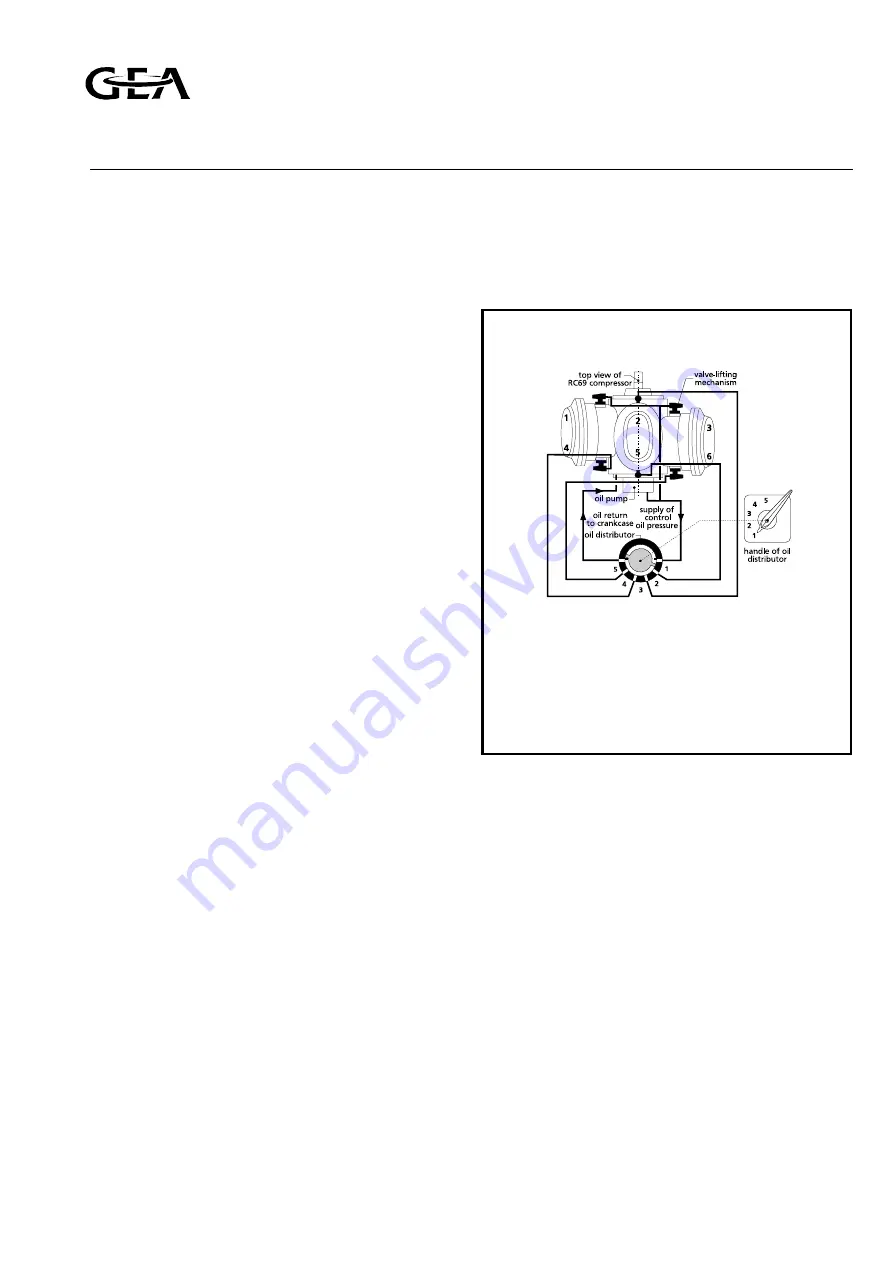

5.5 CAPACITY CONTROL

In order to adapt the compressor capacity of the

cooling load of the moment, a number of cylinders

can be put in or out of action either individually of

collectively. In this case use is made of the valve

lifting mechanism fitted on each cylinder (see

chapter 4) and operated by the pump control oil

pressure.

The capacity control may be of two-fold disign:

a) with a manually operated oil distributor

(single-stage compressors only);

b) with one up to four three-way solenoid valves

which are operated electrically and thus enable

automatic control.

Regardless of the control system applied, one or

more cylinders are connected direct to the control

oil pressure; these cylinders become automatically

operative after the unloaded starting of the

comrpessor. The other cylinders can be cut in or out

in one or more stages.

Especially in the case of two-stage compressors the

use of these switching possibilities can be limited by

the operating conditions of the installation (refer to

the plant manual). Moreover, the number of

switchings per unit of time of one individual

cylinder, as well as of the whole compressor, is tied

to a maximum (see chapter 8, Supervision during

compressor operation).

5.5.1 MANUALLY OPERATED CAPACITY

CONTROL (single-stage compressors only)

(see fig. 5.2)

In this control system the compressor is fitted with

an oil distributor which can be set by hand to

serveral positions. The distributor has six ports:

one for the control pressure connection, one for

the oil return connection and four for the

connection of the valve lifting mechanisms of the

cylinders or cylinder groups. Depeding on the

compressor size, one or more of the last-named

ports may be out of use.

The distributor has five positions. In position 1 the

control pressure is blocked and the valve lifting

mechanisms are connected to the oil return. Only

the cylinders directconnected to the control

pressure are then in operation. In the positions 2,

3, 4 and 5 the control pressure is admitted step by

step to the valve lifting mechanisms of the

connected cylinders or cylinder groups, which then

become operative.

This control system enables the compressor to be

controlled in maximum four steps from minimum

up to maximum capacity. After stopping the

compressor it is desirable to set the oil distributor

again to position 1 (also refer to chapter 7).

A survey of the operating cylinders in the various

positions of the oil distributor is indicated in table

5.1, overleaf.

5.5.2 ELECTRICALLY OPERATED CAPACITY

CONTROL (see fig. 5.3)

For distributing the control pressure to the valve

lifting mechanisms of the cylinders or cylinder

groups, use is made in this system of one up to

four electrically operated three-way solenoid

valves; their number depends on the size of the

compressor. The solenoid valves fitted on the

compressor each have three connections: one for

the control pressure (2), one for the oil return (0)

and one for the valve lifting mechanism (1).

When the valve is not energized, the control

pressure connection in each valve is blocked, and

the valve lifting mechanism is connected to the oil

return, so that the cylinder or cylinder group is out

of action. As soon as the valve is energized, the oil

return is shut off and the control pressure is

admitted to the valve lifting mechanism, causing

FIG. 5.2 SCHEMATIC DIAGRAM OF

THE MANUALLY OPERATED

CAPACITY CONTROL

Refrigeration Division

Grasso

5. DISCRIPTION AND OPERATION OF ACCESSORIES

v002.97.10.en

Refrigeration Compressors Series RC9

Page 5.3