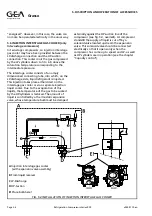

crankshaft by means of three grub screws (7.4)

and a drive pin (3) . The slip ring holder with

carbon insert can slide axially over the crankshaft

and is pressed on to the counter-slip ring by

means of the metal bellows.

O-rings (5 and 7.5) are provided to ensure the

sealing between rotary seal assembly and

crankshaft and between counter-slip ring and

shaft seal housing.

To remove sufficiently the frictional heat

developed by the slip rings, the shaft seal is

incorporated in the lubricating oil circuit (see

further Paragraph 4.10, “Lubrication system”).

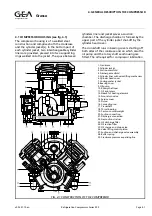

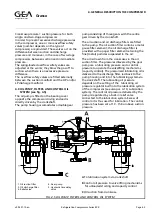

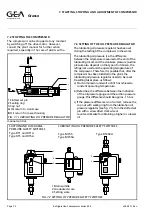

4.4 SUCTION AND DISCHARGE VALVES

(see fig. 4.3)

The suction and discharge valves of the

compressor are of the ring type. They contain

steel valve rings pressed, under spring tension, on

to a seat and shutting off the openings provided

in it. The lift of the valve rings is limited by a

stroke limitor. The suction valve only has one valve

ring retained, together with one sinusoidal spring,

between the valve seat type collar of the cylinder

liner and a stroke limitor.

The stroke limitor of the suction valve is centred

by the collar of the cylinder liner.

The discharge valve consists of a valve seat and a

stroke limitor, fixed together by means of bolts,

and between which the one valve ring, together

with four sinusoidal springs is placed

concentrically. The discharge valve seat and the

suction valve stroke limitor are one and the same.

The whole assembly is pressed on to the collar of

the cylinder liner by a powerful buffer spring. For

the function of this buffer spring, see Chapter 6,

par. 6.3, Liquid Hammer.

Fig. 4.3 only shows schematically the construction

and operation of the suction and discharge valves.

For the real construction, reference is made to

Chapter 9, Compressor Maintenance.

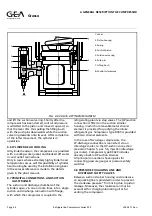

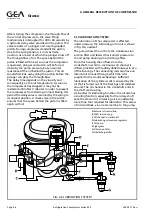

4.5 VALVE LIFTING MECHANISM (see fig. 4.4)

In order to enable the compressor to start

unloaded, all cylinders have be put out of action

mechanically by suction valve ring lifting during

compressor standstill. For this purpose a lifting

bush is provided in each cylinder, which can move

up and down around the cylinder liner. The lifting

bush is provided at the top with push pins capable

of lifting the suction valve ring from its seat via

openings in the collar of the cylinder liner. The

lifting bush is connected with an oil pressure

controlled spring-loaded piston, located in a

housing on the outside of the cylinder jacket, by

means of a lever. The piston can be moved

upward by control oil pressure from the oil pump.

At compressor standstill there is no oil pressure,

the piston is forced down by the spring causing

the lifting bush with push pins to move upwards

FIG. 4.3 SCHEMATIC CONSTRUCTION AND OPERATION OF SUCTION AND DISCHARGE VALVE

1. Buffer spring

2. Spring cup, also discharge

valve stroke limitor

3. Discharge valve ring

with sinusoidal springs

4. Suction valve stroke limitor,

also discharge valve seat

5. Suction valve ring

with sinusoidal springs

6. Cylinder liner, also

suction valve seat

A

Discharge

B

Suction

Refrigeration Division

Grasso

4. GENERAL DESCRIPTION THE COMPRESSOR

v002.97.10.en

Refrigeration Compressors Series RC9

Page 4.3