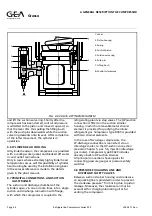

After starting the compressor, the through-flow of

the control oil pressure to the valve lifting

mechanisms is interrupted for 30 to 60 seconds by

a hydraulic delay valve provided in the pump. This

valve consists of a plunger and a spring-loaded

piston. During compressor standstill the piston,

due to the spring tension, is in its extreme

position, as a result of which the plunger shuts off

the through-flow of oil. The space behind the

piston is filled with oil. As soon as the compressor

is operated, plunger and piston will be forced

down by the pump pressure, but encounter

resistance of the oil behind the piston. This oil

should first leak away along the piston before the

plunger can clear the through-flow.

The delay time depends on the viscosity and

consequently on the oil temperature. As soon as

the compressor has stopped, it may not be

restarted until after 3 minutes in order to prevent

the compressor from starting on load. During this

period the delay valve is returned by the spring to

its original position. A check valve in the piston

ensures that the space behind the piston is filled

again with oil.

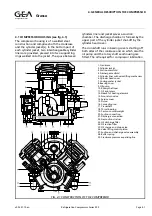

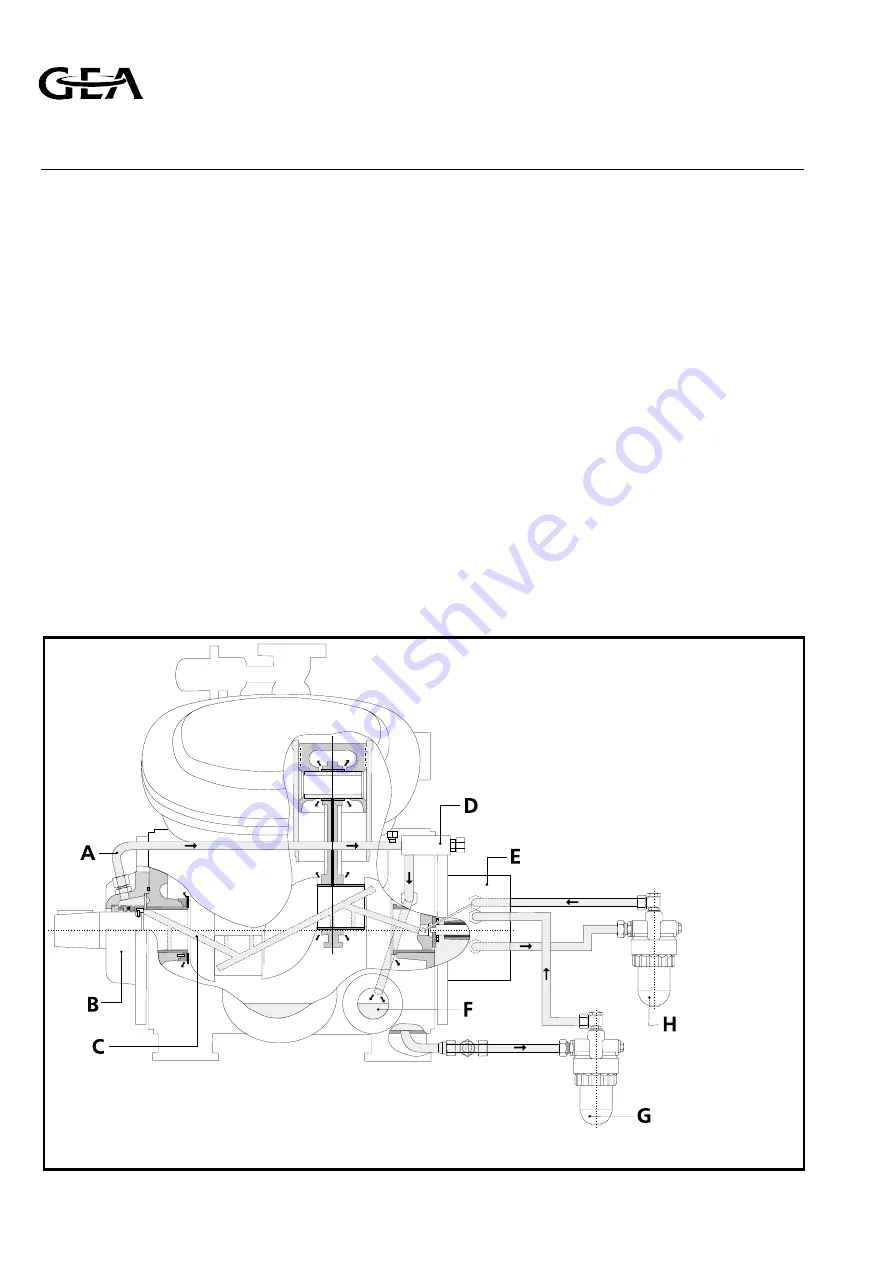

4.10 LUBRICATION SYSTEM

The lubrication of the compressor is effected

under pressure; the lubricating oil circuit is shown

in fig. 4.6, overleaf

The pump draws the oil from the crankcase via a

suction filter and feeds it back under pressure to

the oil pump housing via a discharge filter.

From this housing the oil flows into the

crankshaft, in which a continuous oil channel is

drilled, provided with radially drilled oilways in situ

of the bearings. The connecting rods also have an

internal oil channel through which the oil is

supplied to the small end bearings. Sufficient

lubrication of the cylinder walls is ensured by the

oil that is forced out of the bearings and splashed

around. The oil channel in the crankshaft ends in

the shaft seal housing.

As, besides its lubricating function, the oil also has

a cooling function, especially for the rotary shaft

seal, the amount of circulating oil is considerably

more than that required for lubricaton. This excess

of oil is led back, via an external line to the pump

FIG. 4.6 LUBRICATION SYSTEM

A

External oil return line

B

Shaft seal housing

C

Oil channel in crankshaft

D

Lubricating oil pressure regulator

E

Oil pump

F

Sight glass

G

Oil suction filter

H

Oil discharge filter

Refrigeration Division

Grasso

4. GENERAL DESCRIPTION THE COMPRESSOR

Page 4.6

Refrigeration Compressors Series RC9

v002.97.10.en