Packaged base frame:

The only places that can be used for safe hoisting of the package are the four

hoisting eyes on the steel base frame as shown in the above figure. Prior to

hoisting a compressor package with a V-belt drive arrangement, the factory

mounted drive guard has to be removed. Attach spreader bars to the slings so as

to prevent damage to piping and components.

Warning!

DO NOT use the compressor or motor or oil separator hoisting eyes to

move the package! These hoisting eyes are intended for lifting loose

components only and not for the entire package!

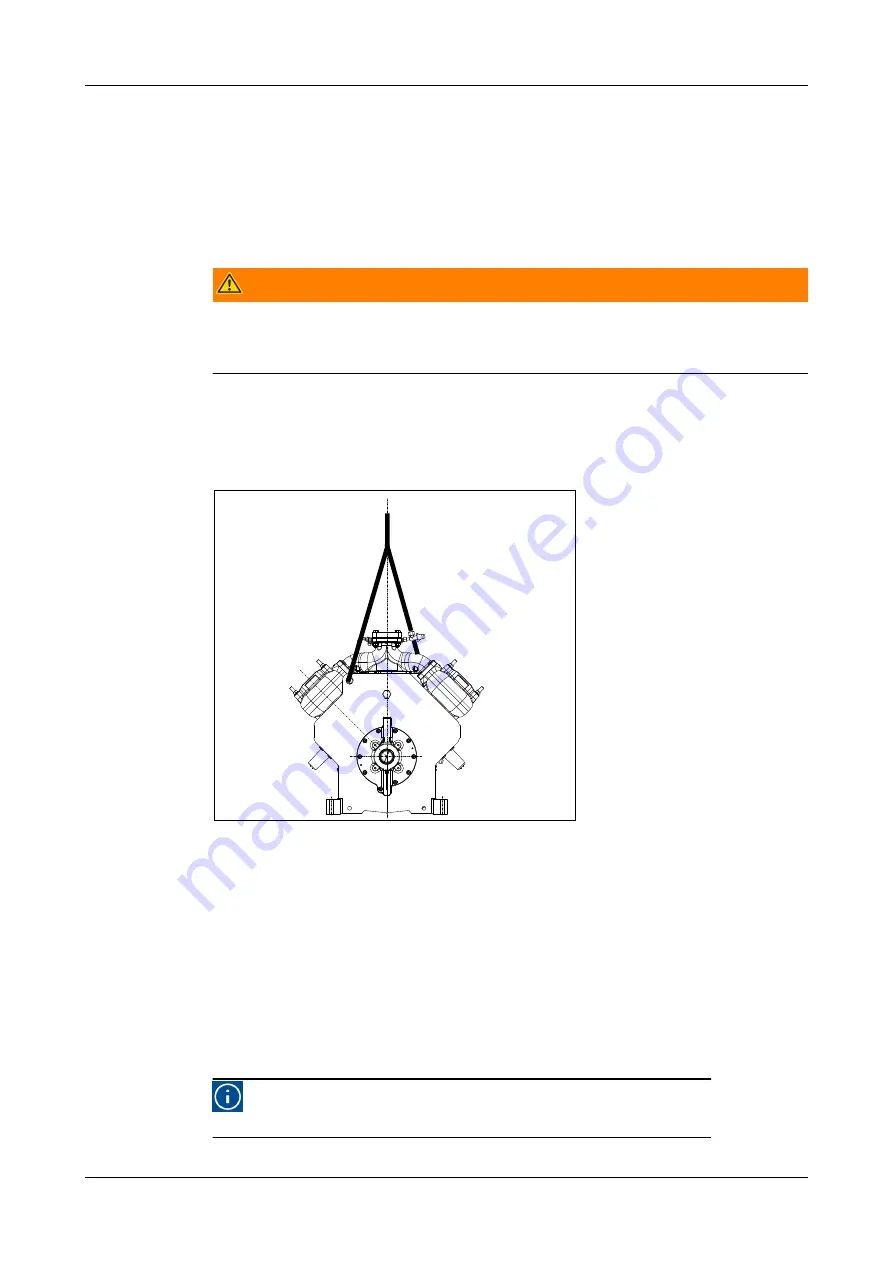

Bare compressor or loose components:

Determine the dead weight of the particular component (see "Product Information

(ED)"), prior to moving a bare compressor or loose component. Use the hoisting

eyes only, DO NOT sling from other compressor parts (see Figure 3, Page 15).

Fig.3:

Hoisting angle

Moving by fork-lift truck

The bare compressor or package can be transported with a fork-lift truck with the

forks spread as much as possible between the skids. To simplify moving, the 2

wooden transport beams must still be mounted underneath the base frame and

stored in this way, until the package is positioned above its approximate location.

1.2.4

Required free space

For easy operating, servicing and maintenance access, the compressor

(package) should be installed with sufficient free space around it.

Hint!

Refer to “Product Information“ for minimum requirements.

INSTALLATION AND PREPARATION FOR USE

INSTALLATION

0089288gbr_11

30.10.2017

15

Summary of Contents for Grasso V 1100

Page 6: ...0089288gbr_11 6 30 10 2017 ...

Page 8: ...0089288gbr_11 8 30 10 2017 ...

Page 10: ...0089288gbr_11 10 30 10 2017 ...