D

GB

F

E

I

Ru

19

09637-06.2015-DGbFEIRu

0

1

2

3

4

5

6

7

8

9

Urspr.

Ers.f.

Ers.d.

Anlagenbezeichnung

Οnderung

Vorblatt:

Datum

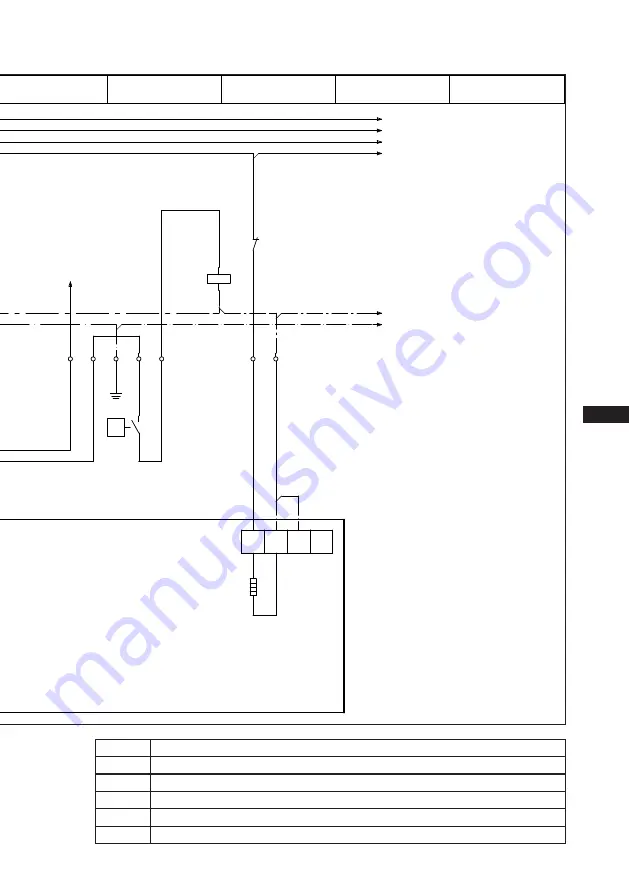

2INT69

Name

Bearb.

Gepr.

Norm

HG34P

R410A/Co2

200308

Kommission:

Gesamtblatt:

Datum

27.05.2015

27.05.2015

11

Kelich

Name

Zeichnungsnummer:

Kundennummer:

Kunde:

Anlage

Bl. Gruppe:

=

2INT69_24V

Ort

Bl.

Fbl.

+

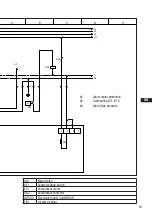

2INT69 (Ohne HA)

2INT69HR60

27.05.2015

ESSG_A1_35_01D

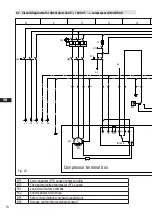

Klemmenkasten Verdichter

A1 Alarm Motorschutz

A2 Übertemperatur BT1, BT2

A3 Alarm Hochdruck

INT69 G

BT1

QA1

FC1

I>

I>

I>

QA2

PE

FC1

A1

FC2

SF1

A2

BP1

P

PE

A3

BP2

P<

PE

QA2

1

2

EB1

QA2

3

4

L1

L2

L3

L1.1

N

PE

11

12

14

L

N

B1 B2

-EC1

3~

M

Θ

BT2

L1

L2

L3

N

PE

QA1

Main switch

SF1

Control voltage switch

EC1

Compressor motor

QA2

Compressor contactor

INT69 G Electronic trigger unit INT69 G

EB1

Oil sump heater

A1

Alarm motor protection

A2

Overheating BT1, BT2

A3

Alarm high pressure