10

D

GB

F

E

I

Ru

96260-08.2015-DGbFEIRu

3

|

Areas of application

30

40

60

80

90

-20

-10

10

0

20

30

t (°C)

o

t (°C)

c

82

-30

50

70

12,5

25

?

t

Oh

<20K

20

t +20°C

Oh

EGD HG88e

R134a

20

10

0

-10

-20

-30

20

30

40

50

60

70

t (°C)

o

t (°C)

c

61

-5

12,5

-25

?

t

Oh

<20K

t +20°C

Oh

R407C

20

10

0

-10

-20

-30

-40

20

30

40

50

60

70

t (°C)

o

t (°C)

c

66

-35

t +20°C

oh

-5

12,5

?

t

oh

<20K

R22

R407F

10

0

-10

-20

-30

-40

-50

20

30

40

50

60

70

t (°C)

o

t (°C)

c

? t

oh

<20K

t +20°C

oh

58

-5

7,5

-45

R404A/R507

t (°C)

o

20

30

40

50

60

70

t (°C)

c

59

?

t

oh

<20K

t +20°C

oh

-20

-15

-25

-10

-5

0

5

10

15

R22

30

40

60

80

90

-20

-10

10

0

20

30

t (°C)

o

t (°C)

c

82

-30

50

70

12,5

25

?

t

Oh

<20K

20

t +20°C

Oh

EGD HG88e

R134a

20

10

0

-10

-20

-30

20

30

40

50

60

70

t (°C)

o

t (°C)

c

61

-5

12,5

-25

?

t

Oh

<20K

t +20°C

Oh

R407C

20

10

0

-10

-20

-30

-40

20

30

40

50

60

70

t (°C)

o

t (°C)

c

66

-35

t +20°C

oh

-5

12,5

?

t

oh

<20K

R22

R407F

10

0

-10

-20

-30

-40

-50

20

30

40

50

60

70

t (°C)

o

t (°C)

c

? t

oh

<20K

t +20°C

oh

58

-5

7,5

-45

R404A/R507

t (°C)

o

20

30

40

50

60

70

t (°C)

c

59

?

t

oh

<20K

t +20°C

oh

-20

-15

-25

-10

-5

0

5

10

15

R404A/R507

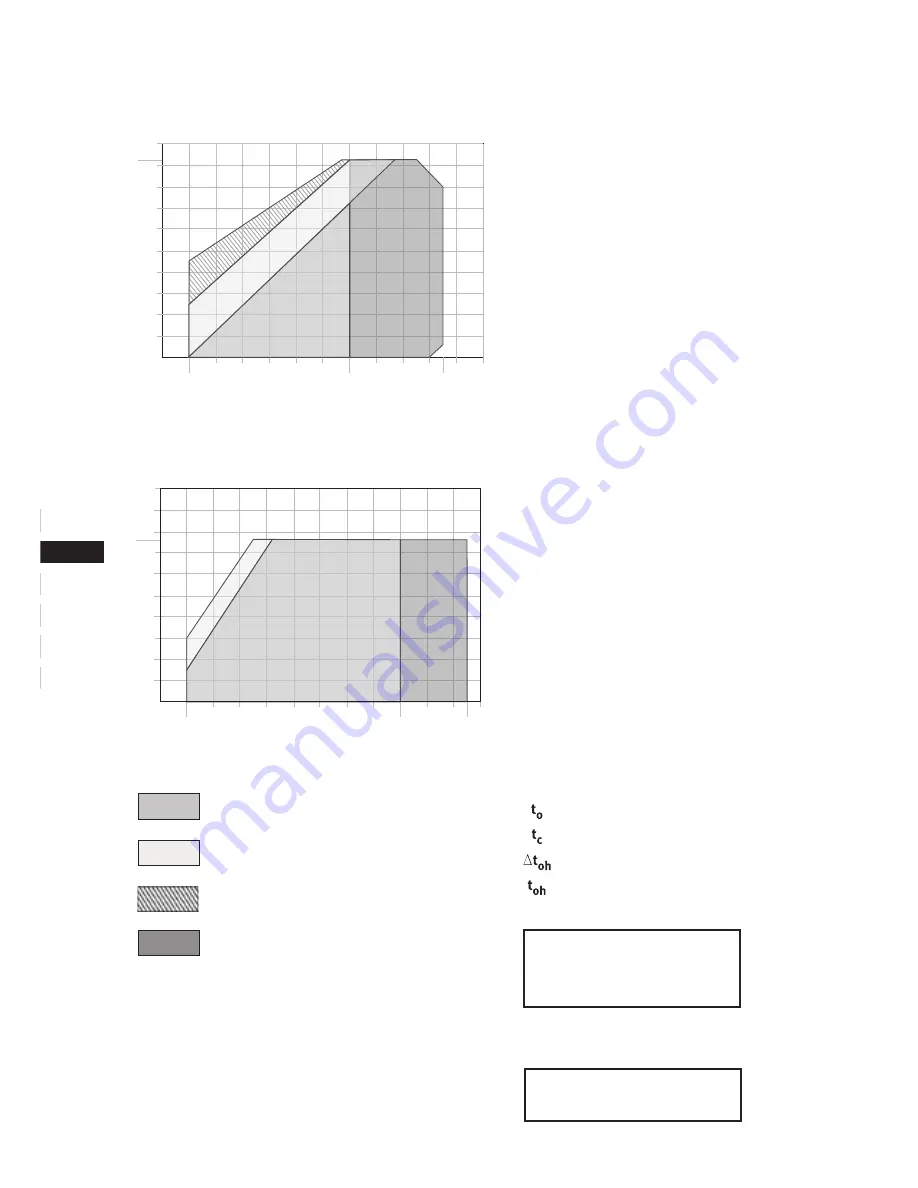

Fig. 7

Fig. 8

Unlimited application range

Supplementary cooling or

reduced suction gas temperature

Supplementary cooling and

reduced suction gas temperature

Motor version S

(more powerful motor)

Evaporation temperature (°C)

Condensing temperature (°C)

Suction gas superheat (K)

Suction gas temperature (°C)

Design for other

areas on request

Maximum admissible

operating pressure (g)

(LP/HP): 19/28 bar

1)

LP = Low pressure

HP = High pressure