18

D

GB

F

E

I

Ru

96260-08.2015-DGbFEIRu

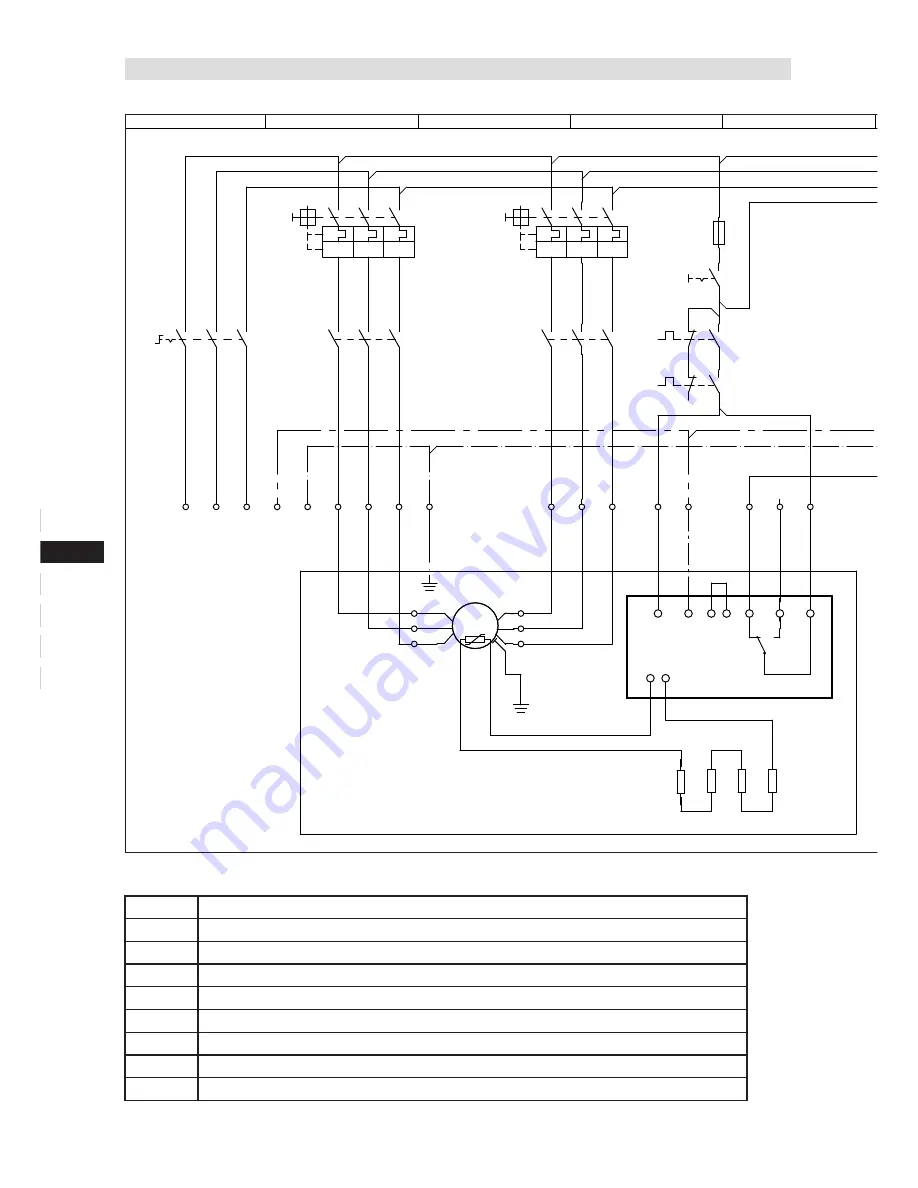

5.3 Basic circuit diagram for part winding start with standart motor

Fig. 23

Οnderung

0

Datum

Name

Datum

Bearb.

Gepr.

Norm

1

20.02.2009

bauknecht

04.03.2015

Urspr.

2

Ers. f.

3

Ers. d.

4

PW MP10

5

6

7

BOCK COMPRESSORS

8

=

+

9

Bl.

6HG76e

Bl.

2

1

X SS

Anschlußkasten Verdichter

BT1

BP1

P-Öl

INT69

QA1

L1

L2

L3

N

PE

FC1.1

I=66%

I>

I>

I>

1

2

QA2

1

3

4

2

5

6

3

1U1

1V1

1W1

EC1

M

/YYY

2U1

2V1

2W1

FC1.2

I=33%

I>

I>

I>

1

2

QA3

4

3

4

5

5

6

6

7

FC1.1

FC1.2

8

BT2

FC2

4A

SF1

BT2

9

BT2

10

BT2

11

QA2

12

T2

13

N

14

L

15

M

16

S

BP2

P>

17

18

19

QA2

BP3

P

20

QA2

KF1

QA3

2.8

3.7

4.8

5HG76e.8

5HGZ76e.7

6HG76e.7

21

22

KF1

2.8

5HG76e.8

5HGZ76e.7

23

24

QA2

25

EB1

26

L1.1

L2.1

L3.1

L1.2

N

PE

OG OG

11

12

14

L

N

B1 B2

BT3

PE

PE

PE

BP1

Oil differential pressure monitor

BP2

High pressure safety monitor

BP3

Safety chain (high/low pressure monitoring)

BT3

Release switch (thermostat)

BT1

Cold conductor (PTC sensor) motor winding

BT2.X

Thermal protection thermostat

EB1

Oil sump heater

EC1

Compressor motor

FC1.1

Motor protection switch (part winding 1)

60%

40%

Compressor terminal box