Malfunction

26

Operating Instructions GEA Orbital Cleaner Jumbo 6

Edition 2016-05-24

Malfunction

In the event of malfunctions immediately deactivate the cleaner and secure it

against inadvertent reactivation. Malfunctions may only be remedied by

qualified staff, who must observe the safety instructions.

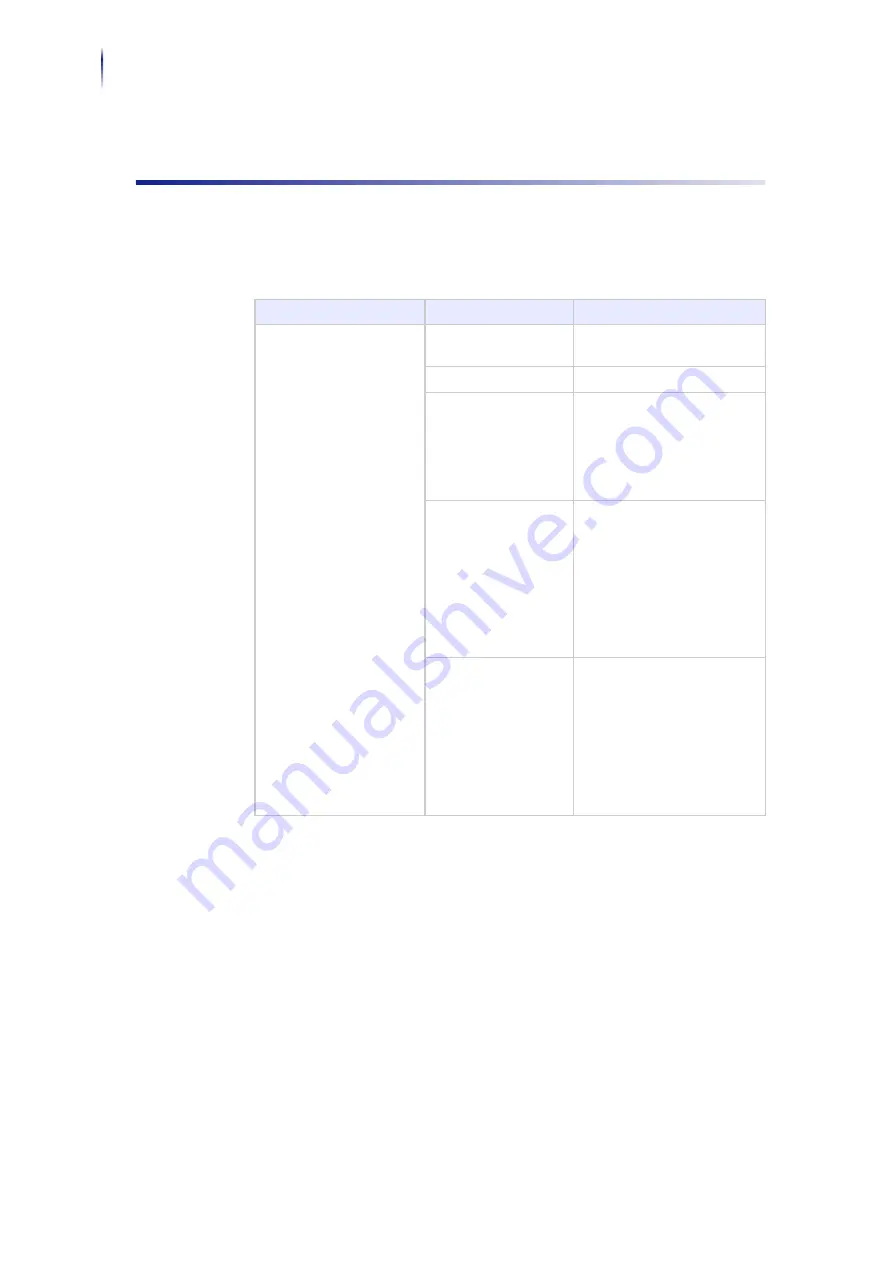

Malfunction

Cause

Remedy

Cleaner does not rotate

and/or

no liquid passes through

the cleaner

Incorrect pressure or

flow rate at the cleaner

Correct the pressure and flow

rate at the cleaner

Strainer blocked

Clean or replace the strainer

Nozzle and stream

straightener blocked

Remove nozzle and stream

straightener and check for

blockage

Leave the cleaner to run

without nozzles. This could

flush out any obstructions.

Motor blocked

Detach the cleaner from the

CIP line and remove the inlet

cap.

Check whether the motor

holes are blocked.

Remove the motor and check

that no obstruction is present

that prevents the vertical shaft

and the rotor from turning.

Bevel gears damaged

or blocked

Place the cleaner upside

down on a firm level surface

and rotate the head assembly

very slowly by the eyebolt.

Check for any hesitation

points as it rotates. If a hesita-

tion point is found, check the

bevel gears for damage or

obstruction at that point.