5

ISOLATED BEFORE MAINTENANCE WORK IS

UNDERTAKEN

Oil Charge

The compressors are pre charged with Polyolester oil.

Following initial start-up, some of this oil will migrate to

other areas of the system. Ensure the oil charge in the

system is adequate as follows :-

The following routine maintenance is required:

Every 3-6 months

The condenser should be cleaned with a soft brush to

ensure correct operation of the condensing unit. When the

condenser coil is obstructed by dirt or rubbish, the unit will

experience high condensing temperatures which will result in

higher running costs, loss of compressor efficiency and

ultimately overheating of the compressor and/or condenser

fans.

•

N2CQ ‘M’ models utilise an oil balance line between

compressors, ensure the oil balance line sightglass

level is 1/2 full when the compressors are not running.

•

N2CQ ‘L’ models are fitted with a separator reservoir,

ensure the oil charge is adequate to show in the upper

sight glass when the compressors are not running.

The pressure relief valve should be inspected for any

pressure release. If a release has occurred or there is a

requirement by the customer maintenance schedule the

relief valve should be changed.

Note: on N2CQ ‘M’ models with oil balance lines, the oil

level may show as empty when only one compressor is

running, this is normal. The true oil level will show when

both compressors are running, or both are at rest.

The PRV MUST be changed every 5 years.

Only suitable Polyolester oil, such as Mobil EAL

Arctic 22 CC (or equivalent), should be used.

Every 12 months

Check security of fixings, especially the fan and motor

mounting. Check refrigerant pipeline for damage and leaks.

Check motor (fans should rotate freely).

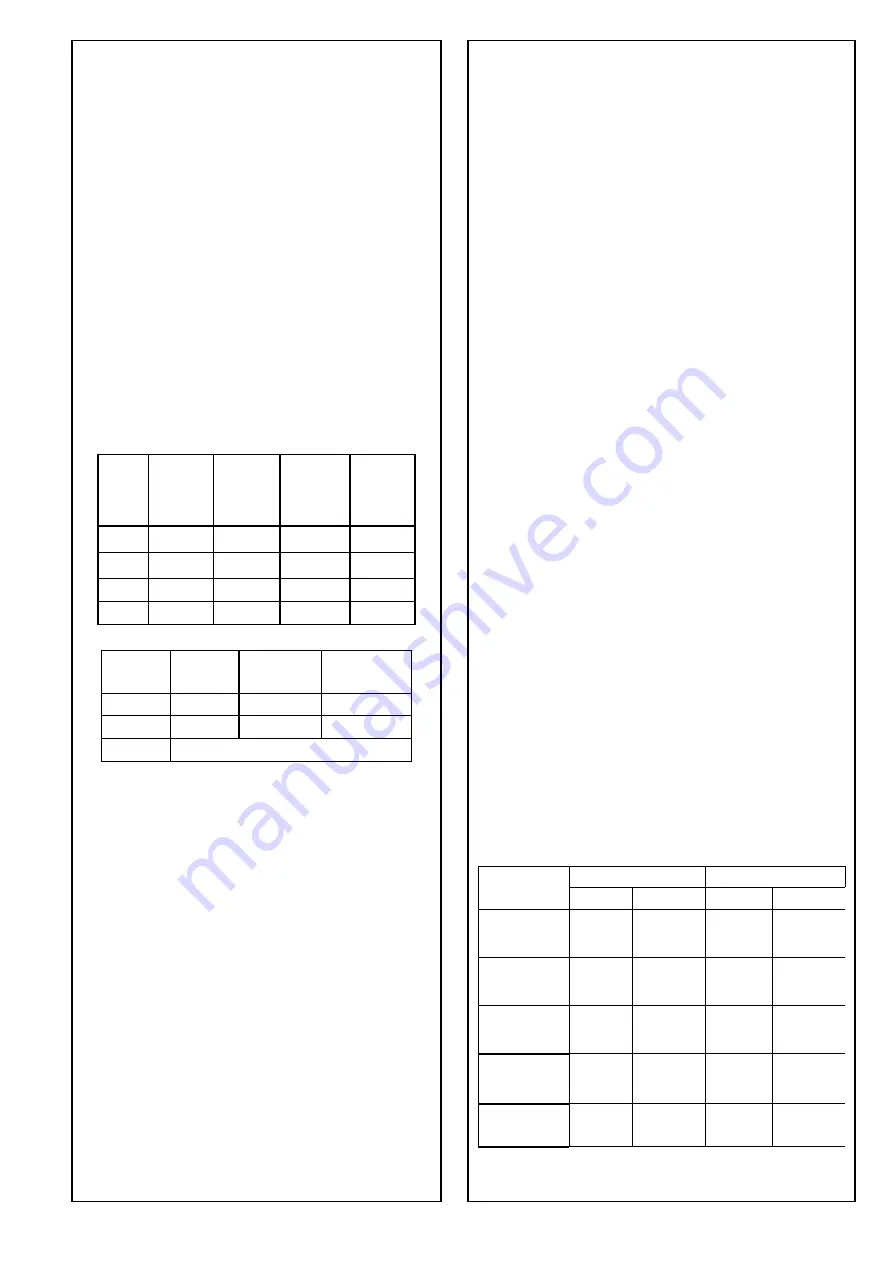

4. OPERATING LIMITS

The HP/LP switch must be set to prevent the unit from

operating outside of its application limits.

Check torque settings of compressor rotalock valves (see

table below).

The LP switch and Step Controller must not be set any

lower than the figures below:

When necessary

R404A & R407C

Clean the fins, guard and general casework. Care must be

taken when cleaning the fins to prevent damage. It is

recommended that a soft brush and mild detergent solution

be used.

Maximum HP

Cut out BarG

Minimum

SST °C

R404A

R407C

LP Cut out

BarG

R407C

Unit

Range

LP Cut out

BarG R404A

R404A

R407C

High-pressure spray washing of the unit must not be

undertaken, as damage to fin coatings and components will

occur. Low-pressure spray washing using specialist coil

cleaning solutions is recommended.

NS/NC-

'MX/S'

-20 2 1.7

25.2

NS/NC-

'LX/S/V'

-40 0.35 N/A 25.2

WARNING! SAFETY GOGGLES MUST BE WORN

DURING THIS OPERATION.

SCQ 'M'

-15

2.7

N/A

25.2

SCQ 'LX'

-35

0.7

N/A

25.2

6. INVALIDATION OF GUARANTEE

Searle accepts no liability, according to Searle's terms and

conditions of sale, for loss or damage arising as a result of:

R134A

Maximum HP Cut

out BarG

Minimum SST

°C

R134a

LP Cut out BarG

R134a

Unit Range

R134a

(i) Failure to install, set up or put to work any part of

equipment in the manner specified in the I&M

instructions, or

'MX/S' -20

0.37

14.4

(ii)

Failure to maintain the equipment in the manner

specified in the I&M instructions, or

'LX/S/V' -20

0.37

14.4

SCQ

Not Suitable for use with R134a

(iii)

Replacement parts, additional parts or accessories

supplied by persons other than Searle having been

incorporated into, or attached to the equipment, or

The LP differential setting must be set high enough to

prevent short cycling of the unit.

(iv) The equipment having been adapted for use, operated

or used in such a way as does not conform to Searle's

recommendations.

The LP Cut-Out pressure is the LP range setting minus

the LP differential setting.

The HP switch must be set at 0.9 x the PRV setting for all

refrigerants. As standard units are fitted with a PRV set to

27.6 BarG, the HP switch must not be set higher than

25.2 BarG.

7. Compressor Rotalock Valve Torques

Discharge Suction

Unit

Size Torque Size Torque

For R134a refrigerant a lower pressure 16 BarG PRV is

available, part number 200-200-528, the HP switch must

not be set any higher than 14.4 BarG.

SCQ7L & 8L

N/A

N/A

1" x 14

60 -70 Nm

SCQ13M to 27M

Multiple Evaporator Applications

SCQ9L & 14L

If the condensing unit is connected to multiple

evaporators operating independently of one another, it is

essential that the saturated suction temperature remains

within the operating limits when the minimum number of

evaporators are running.

1" x 14

60 - 70 Nm

1" x 14

60 - 70 Nm

SCQ31M

NSQ09L to 18L

60 – 70

90 – 100

1" x 14

1 1/4" x 12

Nm

Nm

NSQ15M to 45M

If the saturated suction temperature falls close to or below

the operating limits for medium temperature 'M' units

when the minimum number of evaporators are running,

the use of 'L’ units, or other Searle condensing unit

products should be considered.

NSQ24L to 40L

90 – 100

100 – 120

1 1/4" x 12

1 3/4" x 12

Nm

Nm

NSQ56M to 92M

NSQ48L

100 – 120

140 – 145

1 3/4" x 12

2 1/4" x 12

Nm

Nm

NSQ110M

5. MAINTENANCE

Check compressor rotalocks as described in the

maintenance section ‘Every 12 months’ (p4).

WARNING! THE UNIT MUST BE ELECTRICALLY

Note:

connection sizes are the threaded spud connection

Summary of Contents for Searle NSQ Series

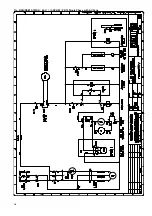

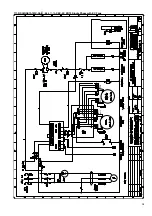

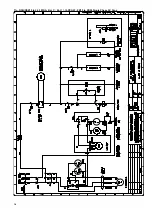

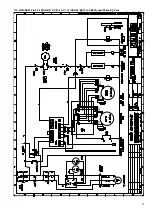

Page 10: ...11a SCQ All Units 1MX A SCQ 611 06 XXX W Single Phase with AC Fans 10...

Page 11: ...11b SCQ All Units 3MX A SCQ 613 06 XXX W Three Phase with AC Fans 11...

Page 14: ...11e NSQ NSE15 1MX A 44 611 16 XXX W ZB15 Single Phase with AC Fans 14...

Page 16: ...11g NSQ NSE19 to 26 1MX A B or C 44 611 06 XXX W ZB19 to ZB26 Single Phase AC Fans 16...

Page 18: ...11i NSQ NSE15 to 45 3MX A B C 44 613 06 XXX W ZB15 to ZB45 Three Phase AC Fans 18...

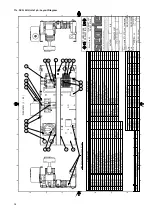

Page 20: ...11k NDQ 30 to 45 3MX S C 44 613 XDX W ZBD30 to ZBD45 Three Phase AC Fans 20...

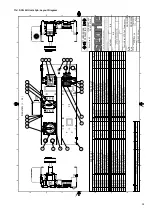

Page 21: ...11l NCQ NCE 56 to 110 3MX S D E 2 3 44 633 16 XXX W ZB56 to ZB11 Three Phase AC Fans 21...

Page 22: ...11m NSQ NSE 15 to 30 1MX S A B C 2 3 44 611 ST2 Layout Diagram 22...

Page 23: ...11n NSQ NSE 09 to 18 3LX S 15 to 45 3MX S A B C 2 3 44 613 ST2 Layout Diagram 23...

Page 24: ...11o NCQ NCE 24 to 48 3LX S 56 to 110 3MX S D E 2 3 44 633 3 ST2 Layout Diagram 24...

Page 25: ...12 DIMENSIONS Case A B C 25...