11

Alarms

11.1

Malfunctions and remedies

In the event of malfunctions immediately deactivate the valve and secure it

against inadvertent reactivation. Malfunctions may only be remedied by qualified

staff, who must observe the safety precautions.

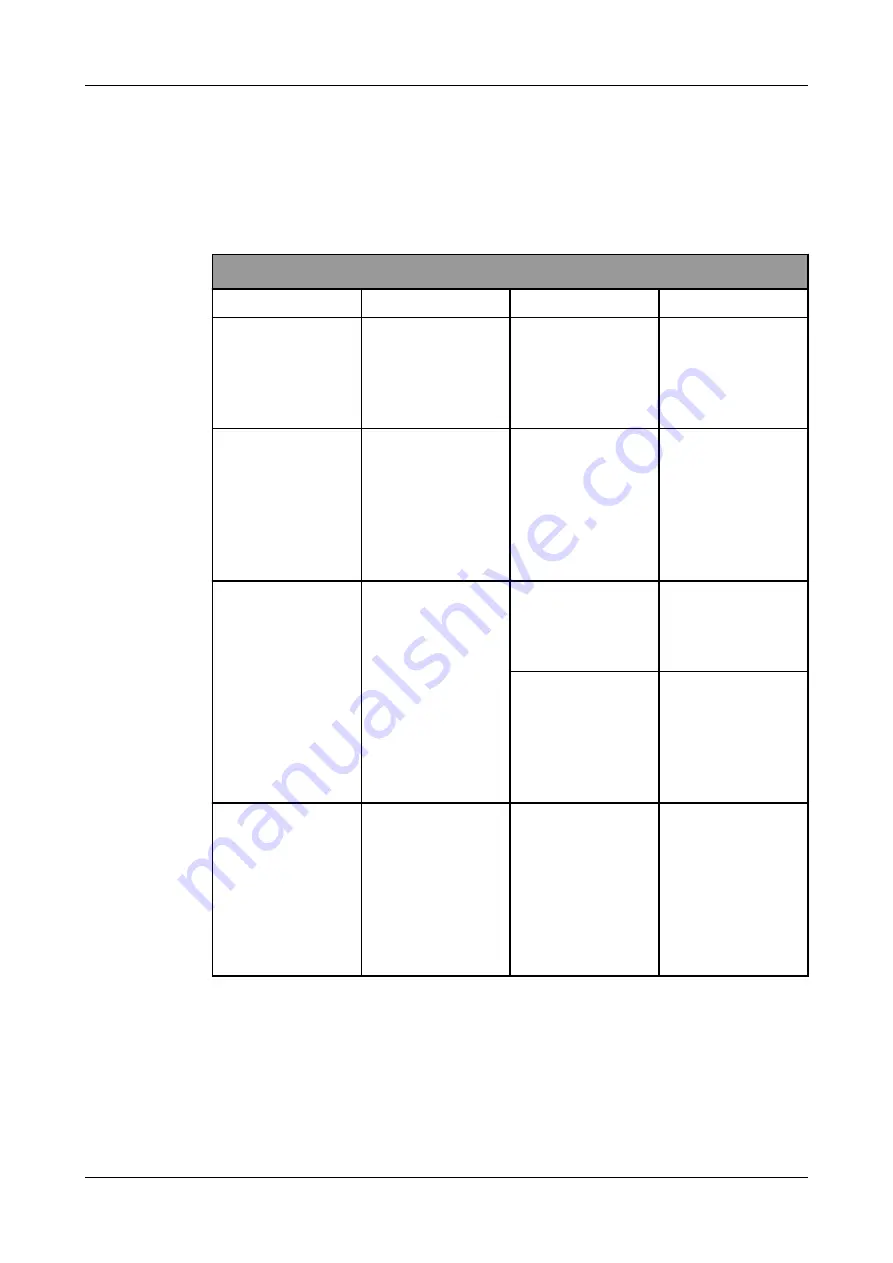

Malfunction, signalling, cause, remedy

Malfunction

Signalling

Cause

Remedy

Activating the

solenoid valves is

not possible after

connecting the

power supply.

No LED is lit

Connecting

terminals for the

power supply

mixed up.

Check the

electrical

connections for

correct wiring.

After connecting

the power supply,

the valve in end

position status

(yellow) is

indicated

immediately.

Yellow

Actuation via

process control

system or the

manual override

device on the

solenoid valve

activated.

Cancel the

actuation.

After connecting

the power supply,

the valve position

is indicated by a

yellow flashing

light.

Flashing yellow

Sensor setting not

correct.

Adjust sensor, see

chapter “Adjust

sensor in control

top”

Switch bar not

fitted correctly.

Control and

tightening of the

switch bar, see

“Installation of the

control top on

different valves”

No signal for the

non-actuated or

actuated position

is pending at the

PLC although one

of the end

positions has

been reached.

Green or yellow

Feedback signals

for the non-

actuated and

actuated positions

to the PLC not

connected.

Correct wiring,

see “Electrical

connection”

Alarms

Malfunctions and remedies

430BAL010697EN_2

104

15.04.2020

Summary of Contents for T.VIS M-15

Page 6: ...430BAL010697EN_2 6 15 04 2020...

Page 53: ...Fig 27 Assembly and installation Electrical connections 430BAL010697EN_2 15 04 2020 53...

Page 55: ...Fig 28 Assembly and installation Electrical connections 430BAL010697EN_2 15 04 2020 55...

Page 119: ...Appendix 430BAL010697EN_2 15 04 2020 119...

Page 120: ......