Malfunction, signalling, cause, remedy

Malfunction

Signalling

Cause

Remedy

Red LED

continuous light

T.VIS P-15

currently in

programming

mode

Wait until

programming

mode ends

Red LED flashing

rapidly

T.VIS P-15 has a

malfunction:

Programmed

position overrun

(possibly from

shape change of

the bellows) only

at 0.3 mm

tolerance setting)

Check the bellows

and possibly

reprogram, see

operating

overview

Section 8.2,

Page 42

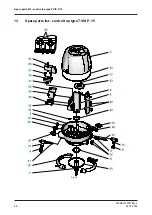

11.2

Carrying out a Reset – Back to Default Standard

Carry out the following steps:

1.

Start the SETUP procedure.

2.

Switch off the operating voltage while running the SETUP.

®

LED goes out, loss of data in the memory module.

3.

Put the control top into operation, see “Commissioning – control top with

solenoid valves“ (Section 7.2, Page 38).

®

Done.

Alarms

Carrying out a Reset – Back to Default Standard

430BAL010747EN_3

56

24.07.2020

Summary of Contents for T.VIS P-15

Page 65: ...Appendix 430BAL010747EN_3 24 07 2020 65 ...

Page 66: ......