GE Appliances

JTP25SH – GE

®

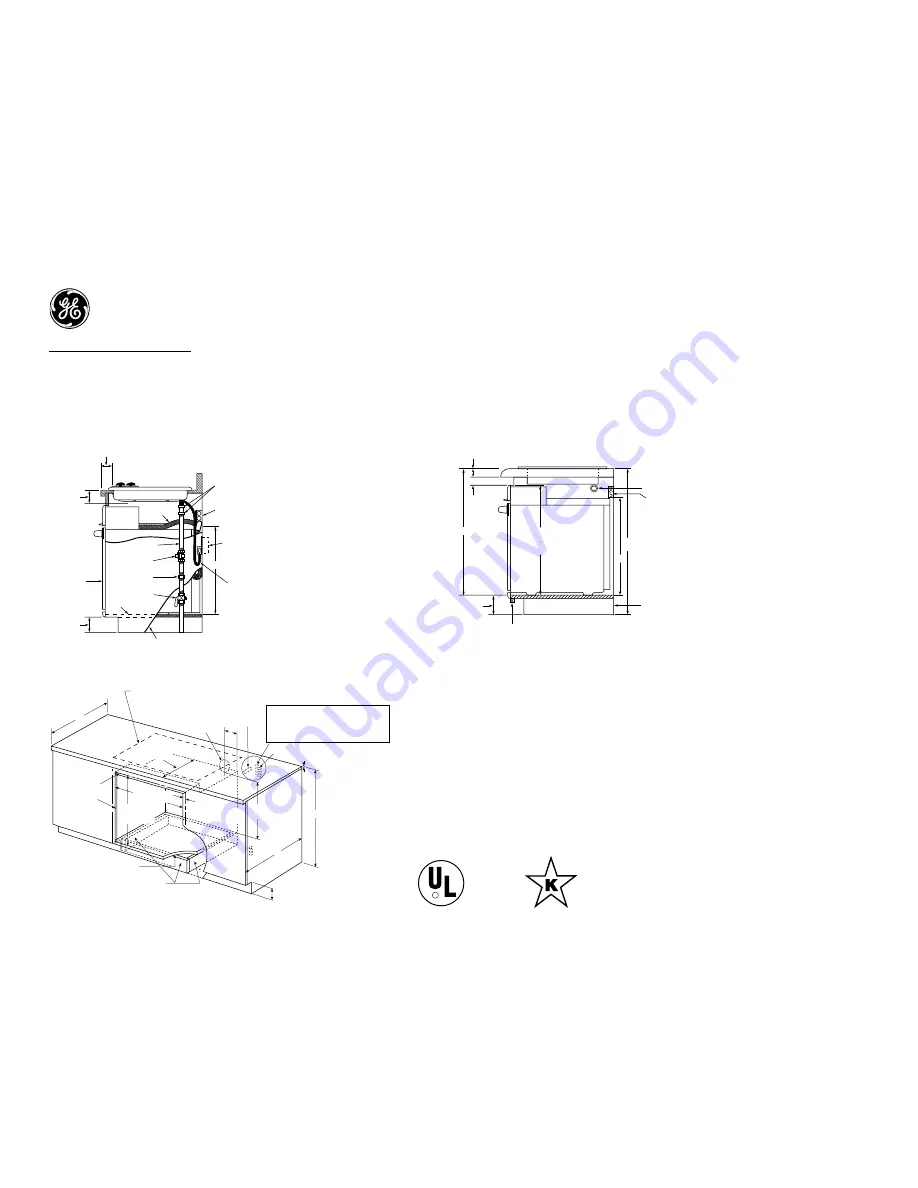

30" Built-In Single Oven

Optional Undercounter Installation

with 36" Gas Cooktop (in inches)

Optional Undercounter Installation With

30" CleanDesign or Sealed Burner Gas Cooktop (in inches)

Specification Revised 2/06

320218

Power cord

for cooktop

Junction box

for oven

Junction box in

adjacent cabinet

for cooktop

hook-up

2 (two) 90

°

elbows &

sufficient pipe to

connect in adjacent

cabinet

Right cabinet side

3/4" Support

Shut-off

valve

Pressure

regulator

1/2" Black

iron pipe

Union

Conduit

(48-1/2" long)

30" built-in

oven

3-1/2" MIN.

Free space

4" To 4-1/2"

3-1/4

22

Side View

5-9/16"

Reference dim. for

MAX. support height

with typical 36" countertop

height

36" Typical

Countertop height

Power cord

Reference

5-9/16

30-7/16

Free space

1-1/2" MIN.

1-1/2" Typical countertop

Side View

22

27-5/16" MAX.

Cutout height

27-1/4" MIN.

Junction box(s) for

oven & radiant

cooktop 22" from

floor

Add suitable filler

to match adjacent

cabinets when needed

to maintain toe kick

alignment

30" Oven W/ Rad. Cktp.

Undercounter Installation (in inches)

5

24

25

Gas or electric cooktops may be installed over

this oven. See cooktop installation instructions

for cutout size. See label on top of oven for

approved cooktop models.

Gas (including the pressure regulator) and

electrical connections for gas cooktop must

be located in an adjacent accessible location.

For a 30" gas cooktop, the connections are

more conveniently made to the right.

120 Volt

Outlet

Gas

connection

Junction box

location

240/208V

36'' MIN.

4'' To 4-1/2 '' Toe kick allowable

Match toe kick height

front and two sides

22'' MIN. above

support platform

Top and/or side

fillers may be

necessary if unit

is positioned

between

existing cabinets

28-1/2'' MIN.

28-5/8'' MAX.

27-1/4'' MIN.

27-5/16'' MAX.

Cutout height

3/4'' Support

platform required

23-1/2" MIN.

Cutout depth

Allow 11/16''

overlap over side

edges of cutout

1-1/2"

Countertop

This installation is to achieve minimum gap between bottom of countertop and control panel.

Note:

For this installation, the bottom trim

will not

be flush with a typical 4" toe kick.

Note:

Cabinets installed adjacent to wall ovens must have an adhesion spec of at least a

194°F temperature rating.

Note:

36" ribbon cooktops (excluding JP969) are approved for use over GE 30" single wall ovens

only. 30" ribbon cooktops (excluding JP939) are approved for use over GE 30" and GE 27" single

wall ovens. Model JP939 can be installed over 27" wall ovens except stainless model JK915 and

JK912SF. Refer to cooktop and wall oven installation information packed with products for current

dimensional data.

Installation Information:

Before installing, consult installation instructions packed with product for

current dimensional data.

R

Listed by

Underwriters

Laboratories

For answers to your Monogram,

®

GE Profile

™

or

GE

®

appliance questions, visit our website at

GEAppliances.com or call

GE Answer Center

®

service, 800.626.2000.