2

、

MAIN SPEIFICATIONS

3

、

TRANSMISSION

)

Headstock spindle speed change:

The motor power is transferred to Headstock axle I through V-belts and then to

headstock main spindle through sliding gears on axle I and axle V, so the main

spindle gets 12 kinds of different speeds.

)

Feeding speed change and thread tooling:

The main spindle works on the gears on axle III and IV through feeding gears, the

different meshing of sliding gears on axle III achieves forward and reverse

rotation.

。

Through a set of final reduction gear and change gears A, B, C to drive

the input axle in feeding box, then through complex gears on second motion shaft,

to make the output axle achieve two different rotation directions and 15 different

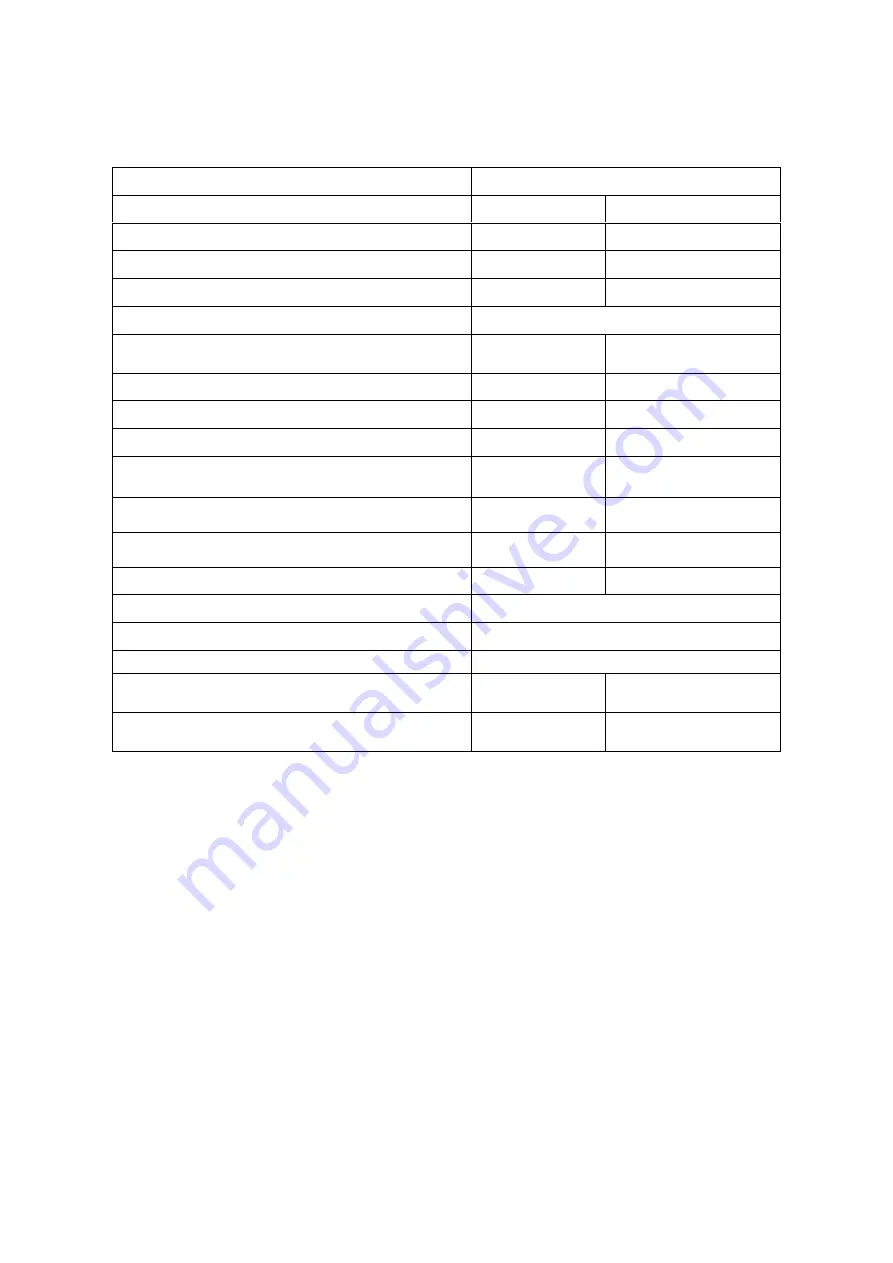

Main parameters

BL250G

Max. swing over bed

250

㎜

9.8

″

Max. work-piece length

500

㎜

19.6

″

Max. swing over carriage

150

㎜

6

″

Main spindle diameter

26

㎜

1.02

″

Main spindle taper

No.4

Main spindle speed

12

96—1920r/r.p.

m

Max. travel cross of toolpost

125

㎜

5.1

″

Max. travel longitudinal of toolpost

75

㎜

3

″

Thread in metric

15

9

Range of thread in metric

0.25

-

2.5

㎜

12

-

96 1/n

″

Toolpost longitudinal feeding per spindle rotation

0.03

-

0.275mm/r

0.00118—0.0106

″

/r

Toolpost cross feeding per spindle rotation

0.015

-

0.137mm/r

0.0059—0.0053

″

/

r

Max. travel of tailstock sleeve

60mm

2.36

″

Tailstock sleeve taper

No.3

Main motor

750W/220V/50HZ

Gross/net weights

180/163

㎏

Overall dimensions

1130×55

0×405

44.5

″

×21.7

″

×

16

″

Packing dimensions

1200×62

0×600

47.3

″

×24.4

″

×

23.7

″