27

Geberit Drainage Systems

Jointing methods

4.7

Jointing methods

for Geberit Silent-db20

Geberit Silent-db20 uses the normal HDPE jointing

methods including butt welding, electrofusion couplings,

and mechanical couplings. If using butt welding the

plaining blades fitted to the butt welding machine must be

changed to carbide steel blades – 240.474.00.1).

Mechanical couplings and electrofusion couplings

are the preferred method of joining to minimise noise

generation, see section 3 for more information.

In addition the following alternative methods of jointing

are available:

4.8

Expansion fittings for

Geberit Silent-db20

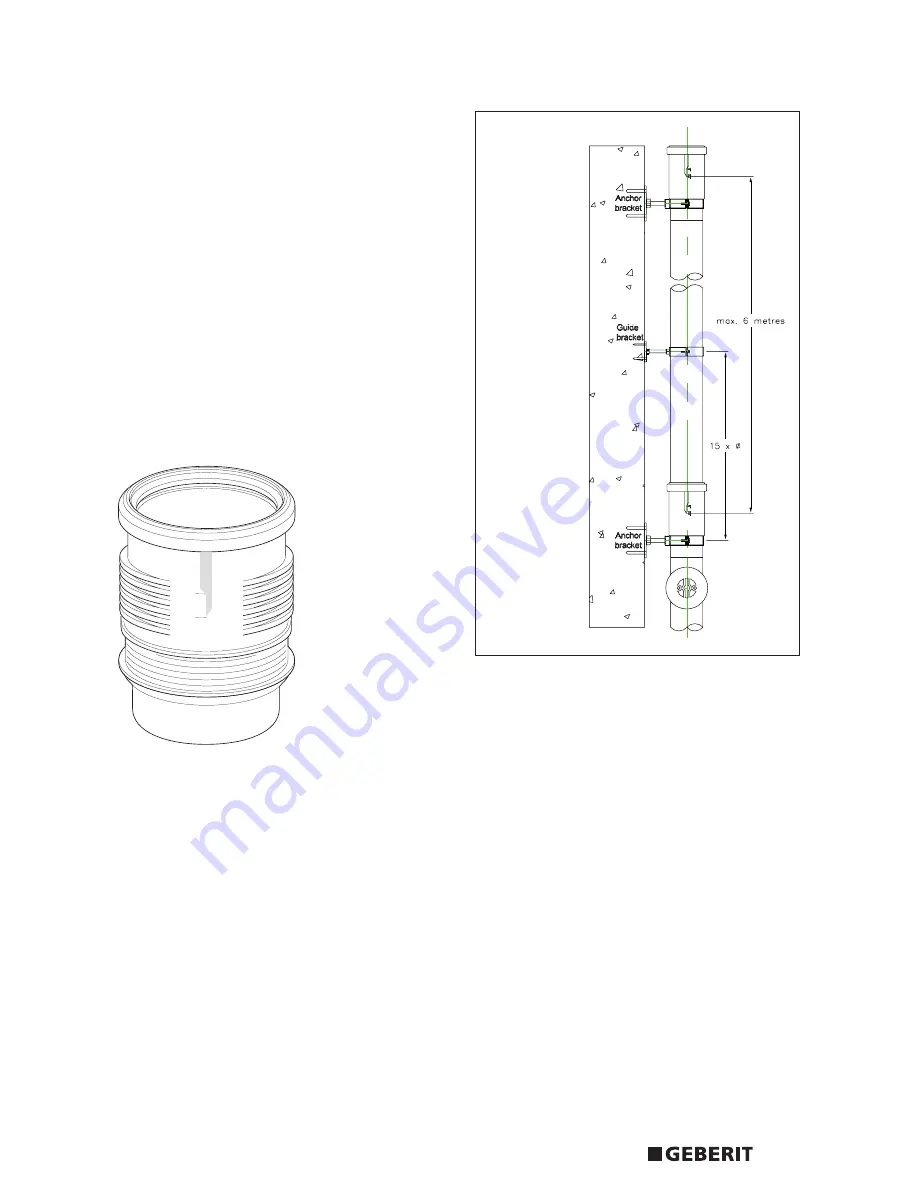

Expansion Socket

Heavily reinforced extended socket with external ribs to

reduce noise transfer.

The coupling can be jointed to other fittings or pipe

using the standard Geberit HDPE electrofusion

coupling. When bracketing the expansion coupling,

use one size larger acoustic brackets, i.e. for 110mm

expansion coupling, use 125mm bracket). Insert pipe

into sealing socket to the insertion markings on the

side of the coupling. The expansion socket must be

anchored to the structure.

This fitting is only available up to size 110mm.

For 160mm expansion, use double sleeve coupling.

Please see following page for more information.

Vertical installation

To minimise stress on the system it is recommended

that an expansion fitting is installed on each floor located

above the highest branch connection within 1 metre of

the floor level using an anchor bracket positioned around

the expansion coupling.

*Maximum 6 metres to next expansion fitting (anchor point)

**Maximum 3 metres when using double

sleeve coupling.

Geberit Silent-db20 uses the normal Geberit HDPE

jointing methods including butt welding, electrofusion

couplings, and mechanical couplings. (If using butt

welding the planing blades fitted to the butt welding

machine must be changed to carbide steel blades –

240.474.00.1).

Example:

Insertion depth

in an ambient

temperature of

20ºC (vertical

assembly).