10

min.3 safety windings

lanyard

2.2. Load

Pay attention to the following with respect to the load:

-

never leave the load unattended whilst elevated

-

do not allow the load to sway

-

never allow the load to fall abruptly from the cable

-

ensure that the hoisting height remains in clear view

2.3. Cable and hoisting material(s)

Pay attention to the following with respect to the cable and hoisting material(s):

-

only use DIN 15020 certified cables with the minimum required breaking force from chart 1.

-

cables and load hook must be regularly checked and maintained according to DIN 15020

-

the sideways leverage angle, the lanyard, must not exceed 3 degrees

-

there must be a minimum 3 safety windings on the first layer of the drum when loaded

-

the top of the last cable layer must have 11/2 x the cable diameter clearance between the outer edge of

the drum flange

-

the cable must be prestressed when being wrapped around the drum

-

never reach into the cable assembly

-

only grasp hold of the cable when wearing safety gloves

-

adhere to the correct cable capacity

-

loading hooks must be fitted with safety catches

-

according to the regulations loading hooks must be mounted to the cable with a thimble and a talurit

clamp

-

the load must be mounted correctly

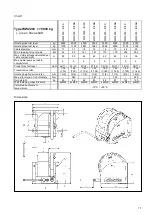

3. Technical details

The type designation is as follows:

WW = range of GEBUWIN worm geared winches for hoisting load 2000, 3000, 4000 or 5000 kg

GR= painted grey colour

EV= zinc-plated

D= 1 cable compartment

2D= 2 cable compartments

GD= grooved cable drum

FS= provided with cable drum free-spool device

FSB= provided with cable drum free-spool device and adjustable friction brake for controlled cable unwinding

safety catch

Summary of Contents for WW2000 D/FS Series

Page 2: ...1 ...