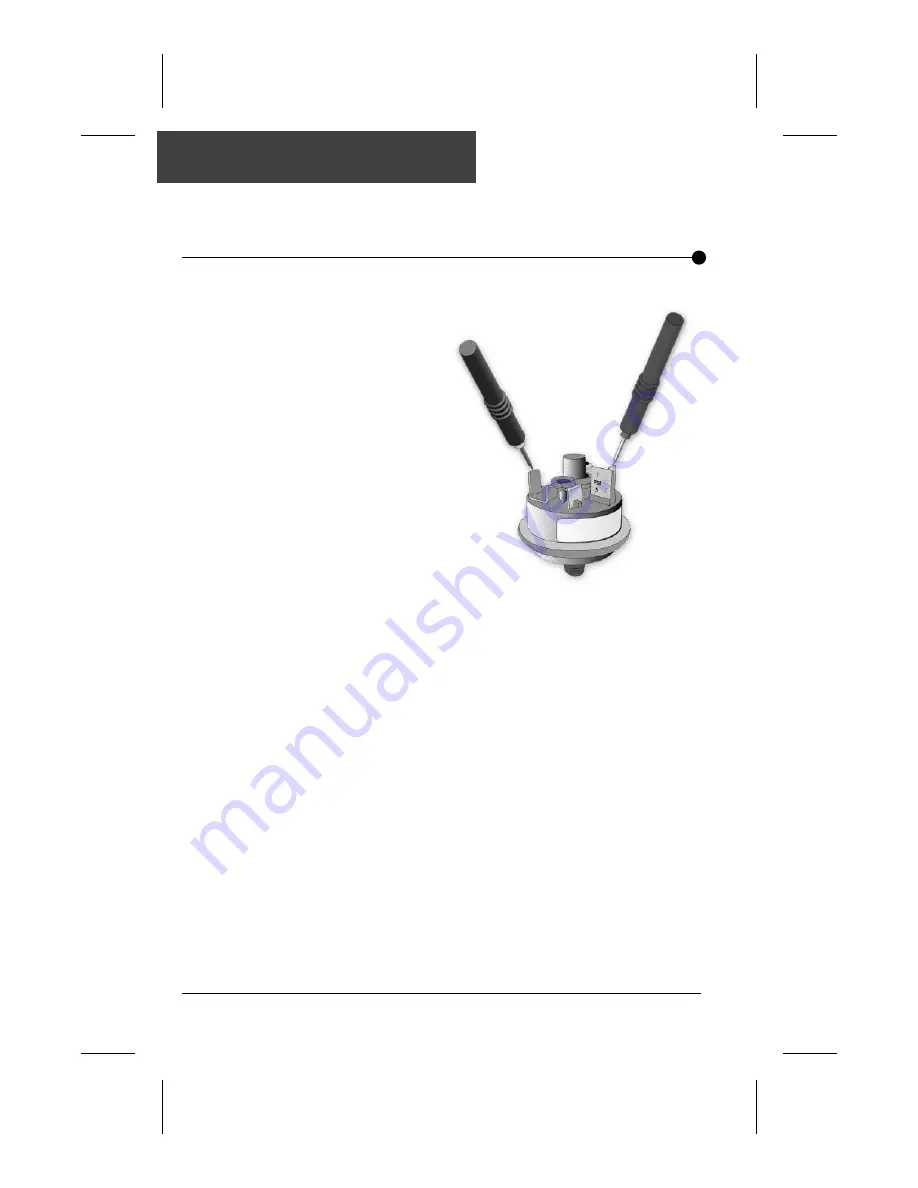

How To Adjust The Pressure Switch

1• Set voltmeter to "

Ω

" (while both

probes are touching one another,

voltmeter should beep to show

there is continuity).

2• Turn Pump 1 off.

3• Do you have continuity on pressure

switch?

If you have no continuity, go to step 4.

If you do have continuity, increase

pressure switch setting by turning

clockwise until voltmeter stops

beeping. Then, increase another

full turn.

4• Turn Pump 1 on at low speed and

wait a few minutes.

If (3) flashing dots do not appear,

you have adjusted the pressure

switch successfully.

If (3) flashing dots appear, decrease

pressure switch setting by turning

counter clockwise until voltmeter

starts beeping (there is continuity).

Then, decrease another 1/4 of

turn. Turn pump off.

The (3) flashing dots should not

appear (restart procedure if (3)

flashing dots appear).

5• When adjustment procedure is

completed, apply Loctite 425 to

the adjustment screw to secure

it in place.

When a voltmeter is available:

76

MC-MP Service Manual

Summary of Contents for MC-MP

Page 2: ...TableofContents ...

Page 4: ...Tools Parts ...

Page 10: ...LowLevelProgramming 9 MC MP Service Manual ...

Page 11: ...10 MC MP Service Manual ...

Page 16: ...FlashingdotsandLEDFlowChart 15 MC MP Service Manual ...

Page 19: ...18 MC MP Service Manual ...

Page 21: ...DisplayIsFlashing 20 MC MP Service Manual ...

Page 23: ...22 MC MP Service Manual ...

Page 29: ...28 MC MP Service Manual ...

Page 36: ...HL OH ErrorCondition 35 MC MP Service Manual ...

Page 39: ...SmartWinterMode 38 MC MP Service Manual ...

Page 43: ...42 MC MP Service Manual ...

Page 44: ... SpaNotHeating FlowChart 43 MC MP Service Manual ...

Page 45: ...SpaNotHeating 44 MC MP Service Manual ...

Page 46: ...SpaNotHeating 45 MC MP Service Manual ...

Page 47: ...46 MC MP Service Manual ...

Page 48: ...PumpFlowChart 47 MC MP Service Manual ...

Page 49: ...Pump1DoesNotWork 48 MC MP Service Manual ...

Page 51: ...Pump2DoesNotWork 50 MC MP Service Manual ...

Page 53: ...52 MC MP Service Manual ...

Page 54: ...BlowerFlowChart 53 MC MP Service Manual ...

Page 55: ...BlowerDoesNotWork 54 MC MP Service Manual ...

Page 57: ...56 MC MP Service Manual ...

Page 58: ...SpaLightFlowChart 57 MC MP Service Manual ...

Page 59: ...SpaLightDoesNotWork 58 MC MP Service Manual ...

Page 61: ...OzonatorDoesNotWork 60 MC MP Service Manual ...

Page 62: ...CirculationPumpFlowChart 61 MC MP Service Manual ...

Page 63: ...CirculationPumpNotWorking 62 MC MP Service Manual ...

Page 64: ...KeysFlowChart 63 MC MP Service Manual ...

Page 65: ...KeysAren tWorking 64 MC MP Service Manual ...

Page 66: ...HowToReplaceTheBoard 65 MC MP Service Manual ...

Page 69: ...HowToReplaceTheHeater 68 MC MP Service Manual ...