Summary of Contents for A10

Page 1: ...Geeetech A10 Desktop 3D Printer USER MANUAL ...

Page 4: ...9 5 Printing quality optimization 51 10 Specifications 51 11 Contact us 53 ...

Page 23: ...SHENZHEN GETECH TECHNOLOGY CO LTD 19 ...

Page 24: ...SHENZHEN GETECH TECHNOLOGY CO LTD 20 ...

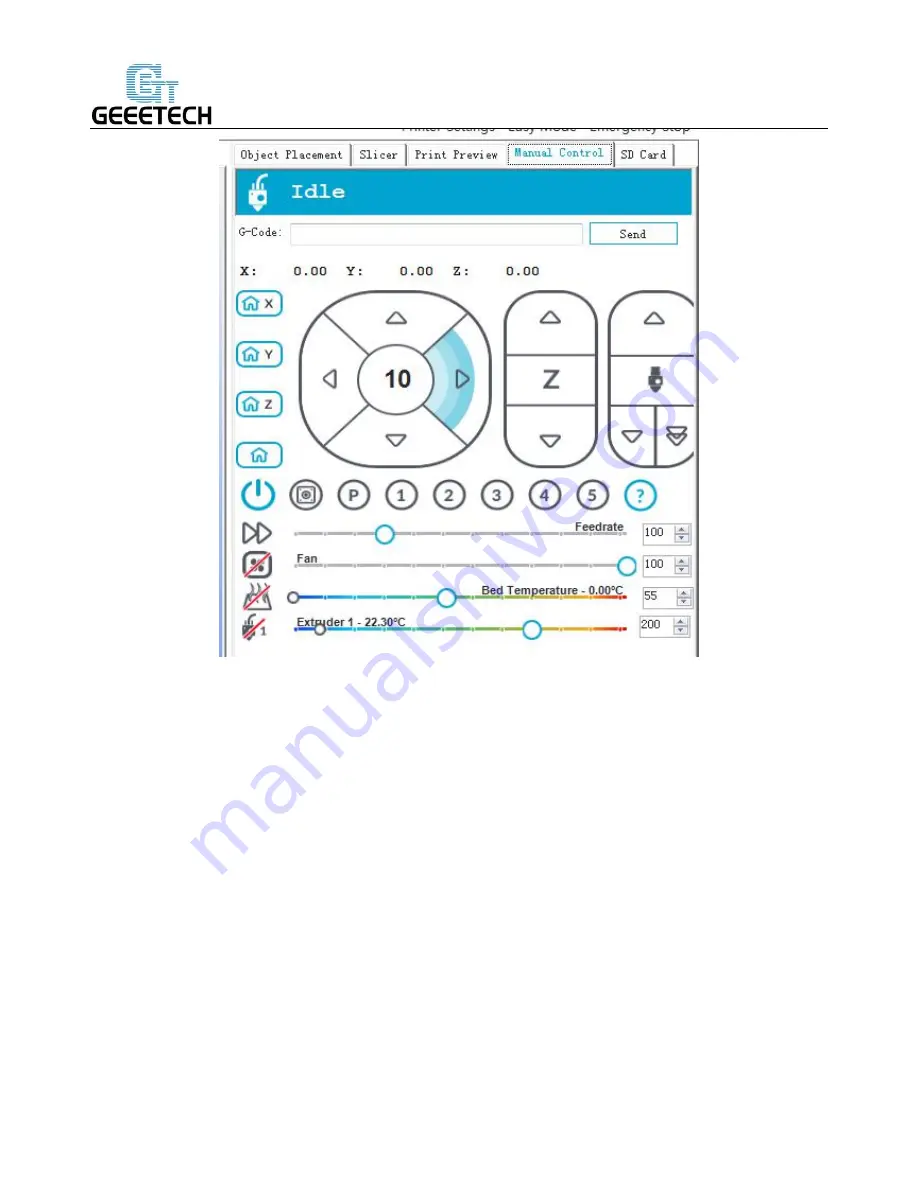

Page 36: ...SHENZHEN GETECH TECHNOLOGY CO LTD 32 You can set the printing speed here ...

Page 39: ...SHENZHEN GETECH TECHNOLOGY CO LTD 35 Number of extruder 1 ...

Page 42: ...SHENZHEN GETECH TECHNOLOGY CO LTD 38 Direct to the file A10 PLA config ini and open it ...

Page 44: ...SHENZHEN GETECH TECHNOLOGY CO LTD 40 Click to save in the tab of Filament Settings ...

Page 45: ...SHENZHEN GETECH TECHNOLOGY CO LTD 41 Click to save in the tab of Printer Settings ...

Page 58: ...SHENZHEN GETECH TECHNOLOGY CO LTD 54 ...

Page 59: ...www geeetech com ...