ShenZhen GETECH CO.,LTD

42

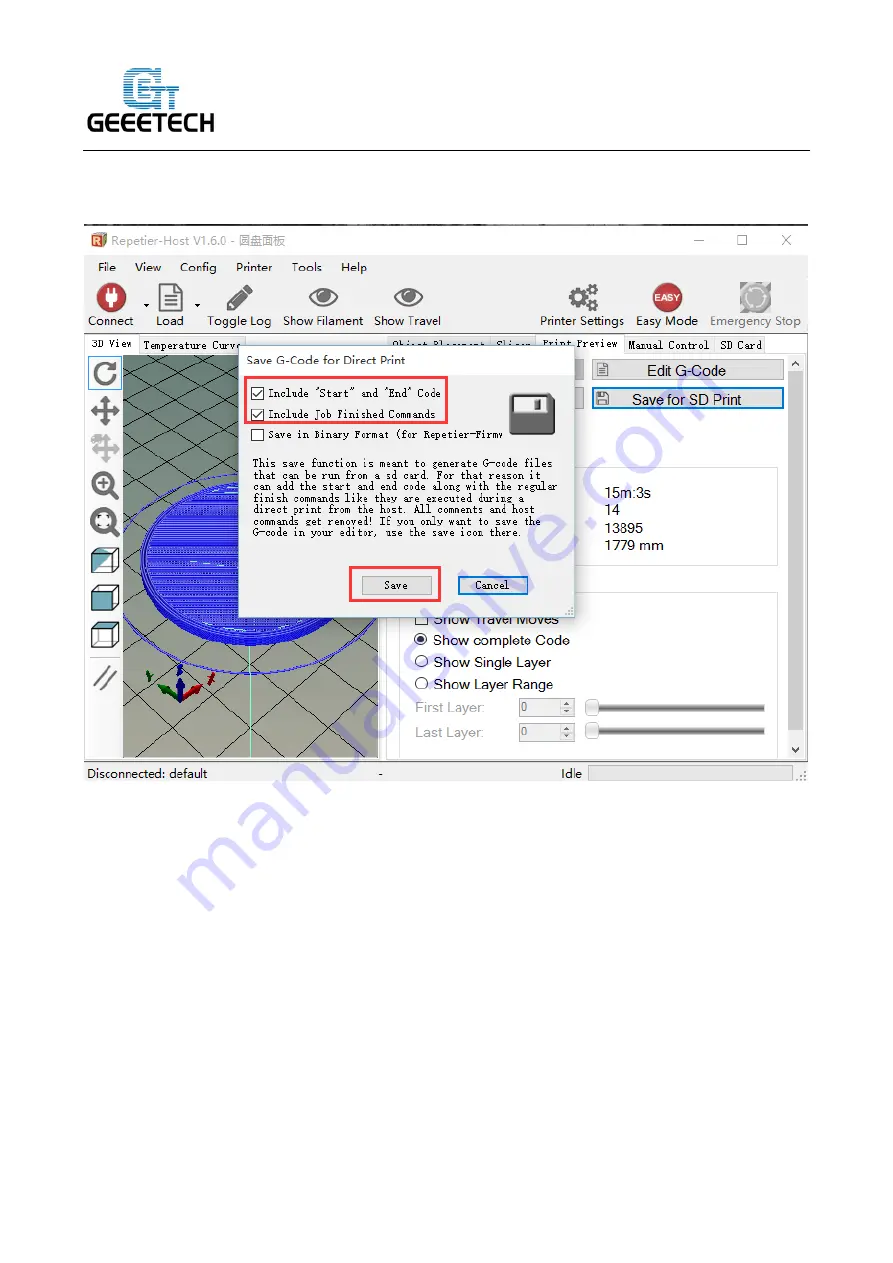

7.3.1 Save

Click Save for SD Print,

and

select the save button in the dialog box.

Summary of Contents for PrusaI3 X

Page 1: ...Geeetech PrusaI3 X User Manual ...

Page 6: ...www geeetech com ShenZhen GETECH CO LTD 3 box of printer settings will appear ...

Page 17: ...www geeetech com ShenZhen GETECH CO LTD 14 ...

Page 29: ...www geeetech com ShenZhen GETECH CO LTD 26 You will be presented with the following interface ...

Page 33: ...www geeetech com ShenZhen GETECH CO LTD 30 ...

Page 36: ...www geeetech com ShenZhen GETECH CO LTD 33 Open slic3r File Load Config ...

Page 43: ...www geeetech com ShenZhen GETECH CO LTD 40 Last step click button to print ...