6

85198A_Manual of Electrical Installation for Pressure Probes KH-SIL2-Mobyle-series_07-2019_ENG

5. Safety (content according to IEC/EN 62061 paragraph 7)

Restrictions on use

The device in order to remain compliant with the designated category should be used only as indicated in these instruc-

tions and as required in the operating manual concerning mechanical installation, electrical connection, environmental

conditions and usage limits.

The sensors must be powered with non-distributed networks and always at lengths of less than 30 mt.

Maintenance and periodic inspections

Periodic maintenance to carry-out in order to guarantee the justified exclusion of failures are:

- Visual inspection of the status of the electrical and mechanical connections.

The maintenance is designed to evaluate possible problems due to situations of incorrect mounting endured over time

or particular aggressiveness of the material processed.

Frequency: every two years

Check obstruction of the channel under pressure

- The maintenance has the purpose to verify that there are no occlusion of the pressure channel, which would lead to

malfunctioning.

The inspection is visual, after removing the probe from the process seat.

Frequency: every year.

Testing the sensor calibration

- The test is intended to check the correctness of the transduction curve of the sensor. It’s done by applying known

pressure points to the transducer and checking the output values of the probe.

Frequency: every four years.

Indication of response time

The response time to the pressure transduction is equal to 1 ms

Indications and alarms

The KH Series pressure sensors in the case of some specific anomalies provide output saturation (positive HIGH or

negative LOW).

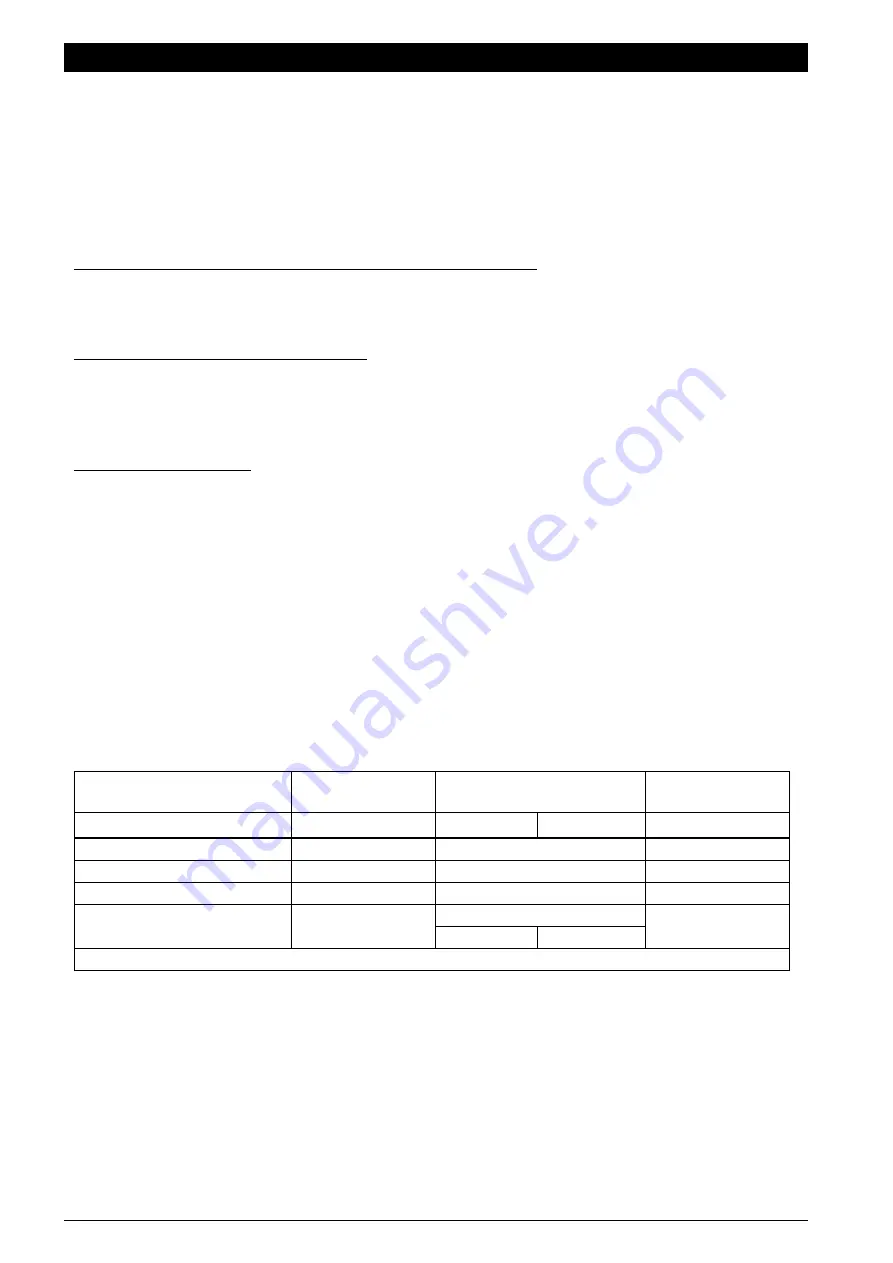

The table 1 indicates the detected failures, their effect on the electrical output, and the recovery mode of the device.

Table 1: failures, effects on the outputs

Failure

Current

output

Voltage

output

Ratiometric

FS<= 6V

FS > 6V

Power supply 5V

Power supply cable broken

LOW < 3.8mA

LOW < 0.05 V

LOW < 0.25 V

Sensor not connected

LOW < 3.8mA

LOW < 0.05 V

LOW < 0.25 V

Power supply broken

LOW < 3.8mA

LOW < 0.05 V

LOW < 0.25 V

Broken bridge

*LOW < 3.8mA

*LOW < 0.05 V

*LOW < 0.25 V

*HIGH > 22mA

*HIGH > 7 V

*HIGH > 11.5 V

*HIGH > 4.75 V

(*) variable according to the type of failure