50950106/AP0313

91

Tires

Inflating or servicing tires can be dangerous.

When possible, trained personnel should ser-

vice and mount tires. To avoid possible death or serious injury,

follow the safety precautions below.

To keep tire wear even, rotate the tires from front to rear and rear to front.

It is important to keep the same size tire on each side of the loader to prevent

excessive wear on tires, chains, or other damage. If different sizes are used, tires

will be turning at different speeds, causing excessive wear.

Note:

The tread bars of all tires should point the same direction.

BE SURE the rim is clean and free of rust.

Lubricate the tire beads and rim flanges with a soap solution. Do NOT use oil

or grease.

Use a clip-on tire chuck with remote hose and gauge, allowing you to stand

clear while inflating the tire.

NEVER inflate beyond 35 psi (240 kPa) to seat the beads. If the beads have

not seated by the time the pressure reaches 35 psi (240 kPa), deflate the

assembly, reposition the tire on the rim, lubricate both parts and re-inflate.

Inflation pressure beyond 35 psi (240 kPa) with unseated beads may break the

bead or rim with explosive force sufficient to cause death or serious injury.

After seating the beads, adjust the inflation pressure to the recommended

operating pressure.

Do NOT weld, braze or otherwise attempt to repair and use a damaged rim.

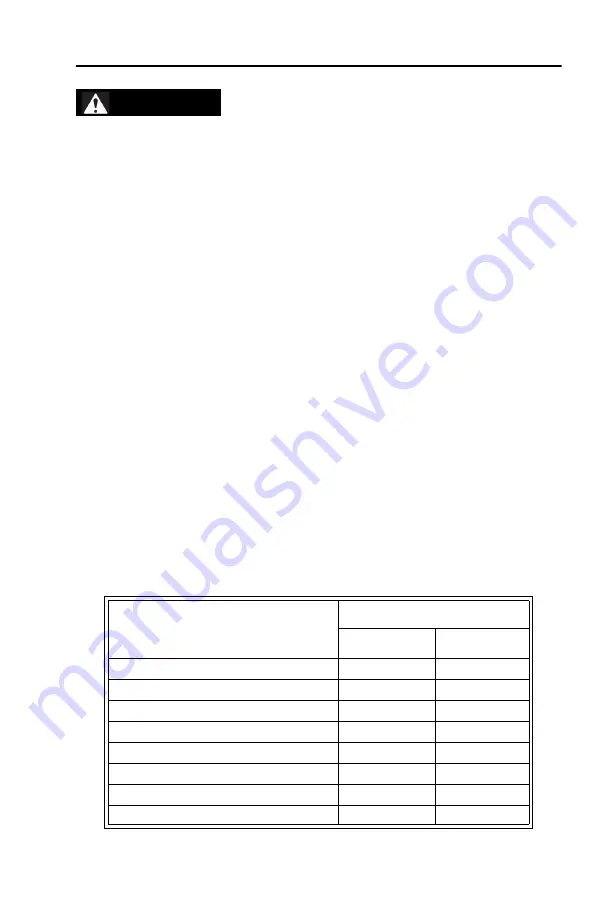

Checking Tire Pressure

Correct tire pressure should be maintained to enhance operating stability and

extend tire life. Refer to the chart below for proper inflation pressures.

Tire Size

Inflation Pressure

psi

kPa

10 x 16.5 8-ply HD Flotation

60

415

10 x 16.5 10-ply Severe-Duty

65

450

12 x 16.5 10-ply HD Flotation

65

450

12 x 16.5 12-ply Severe-Duty

65

450

33 x 15.5 x 16.5 Extra-Wide Flotation

60

415

14 x 17.5 12-ply HD Flotation

65

450

14 x 17.5 14-ply HD Flotation

65

450

14 x 17.5 14-ply Severe-Duty

65

450

WARNING

Summary of Contents for R190

Page 1: ...Skid Steer Loaders Operator s Manual Form No 50950106 AP0313 English R190 R220 R260 ...

Page 4: ......

Page 22: ...18 50950106 AP0313 Notes ...

Page 36: ...32 50950106 AP0313 Information Center Electronic Display cont ...

Page 37: ...50950106 AP0313 33 Information Center Electronic Display cont ...

Page 50: ...46 50950106 AP0313 Notes ...

Page 86: ...82 50950106 AP0313 Engine Diagnostic Chart ...

Page 87: ...50950106 AP0313 83 Engine Diagnostic Chart cont ...

Page 88: ...84 50950106 AP0313 Engine Diagnostic Chart cont ...

Page 89: ...50950106 AP0313 85 Engine Diagnostic Chart cont ...

Page 90: ...86 50950106 AP0313 Engine Diagnostic Chart cont ...

Page 108: ...104 50950106 AP0313 Maintenance Log Date Hours Service Procedure ...

Page 109: ...50950106 AP0313 105 Maintenance Log Date Hours Service Procedure ...

Page 110: ...106 50950106 AP0313 Maintenance Log Date Hours Service Procedure ...

Page 122: ...118 50950106 AP0313 Notes ...