Instructions for Use: GEV019-100

Page 54

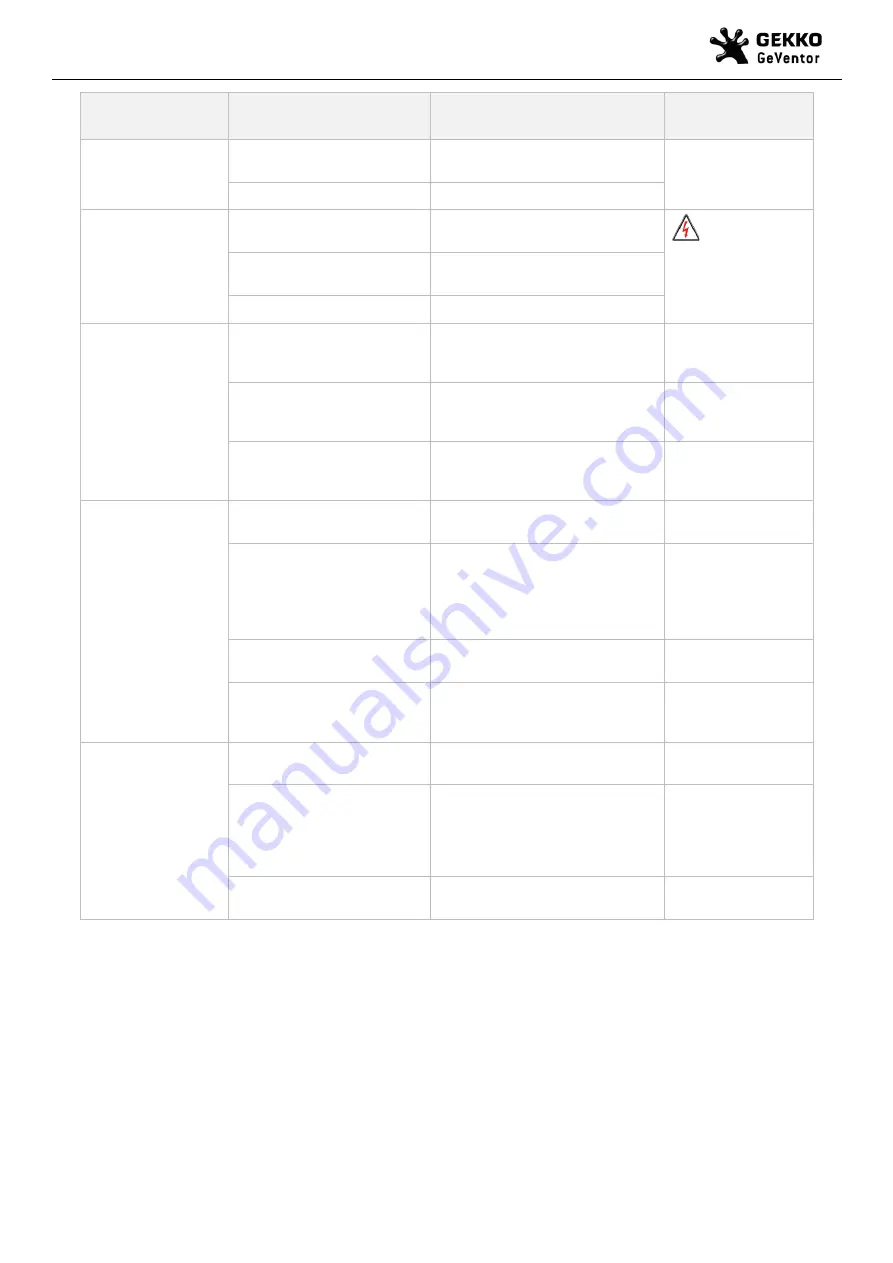

Fault

Possible Cause

Counter Measures

Notes

Inlet Gas Low Pressure

Alarm

Oxygen/Air Leak

Check ventilator tubing for signs of

damage.

Oxygen/Air Disconnection

Reconnect to supplies.

High Airway Pressure

Alarm

Kink in tubing

Check tubes for bends or objects resting

on tubing

High gas flowrate setting

Reduce gas flowrate using Gas Flow

(Slope) Control Knob

Physical blockage

Tubing to replaced and/or cleaned.

PEEP not Achieved

PEEP valve is not set to same

setting as target PEEP value on

HMI

Check PEEP valve is set correctly

PEEP valve is disconnected from

unit

Check PEEP valve is properly installed

onto GeVentor Expiration Valve or Bio-

filter

GeVentor Expiration Valve is

damaged

Remove GeVentor Expiration Valve and

inspect. If diaphragm is damaged,

replace diaphragm.

Contact

the

manufacturer for spare

parts if required.

Intended Tidal Volume

or Target Pressure not

Achievable

Oxygen / Air Leak

Check ventilator tubing for signs of

damage.

Patient

circuit

components

damaged and/or not connected

properly

Inspect patient circuit for leaks or

damage.

Ensure all hose connections are tight

and

no

obstructions

on

any

hose/tubing.

Target Volume Setpoint not

reached

Verify patient details (height and

gender) on VCV or PCV page of HMI.

Target Volume or Pressure

Setpoint not reached

Adjust Gas Flowrate Knob to achieve

required gas flow with each inspiration

at set inspiration time.

Refer to Section 6

(Operating Instructions)

for more detail.

Incorrect FiO

2

Ratio

Damaged gas mix valve

Inspect the FiO

2

gas mix valve and

replace if damaged.

Calibration of oxygen sensor is

due

Check calibration date and ensure

compliance within the six month period

of calibration. If required call the

manufacturer or an approved service

technician to complete calibration.

Incorrect Settings

Check and confirm if the settings

entered on the HMI are correct.