11

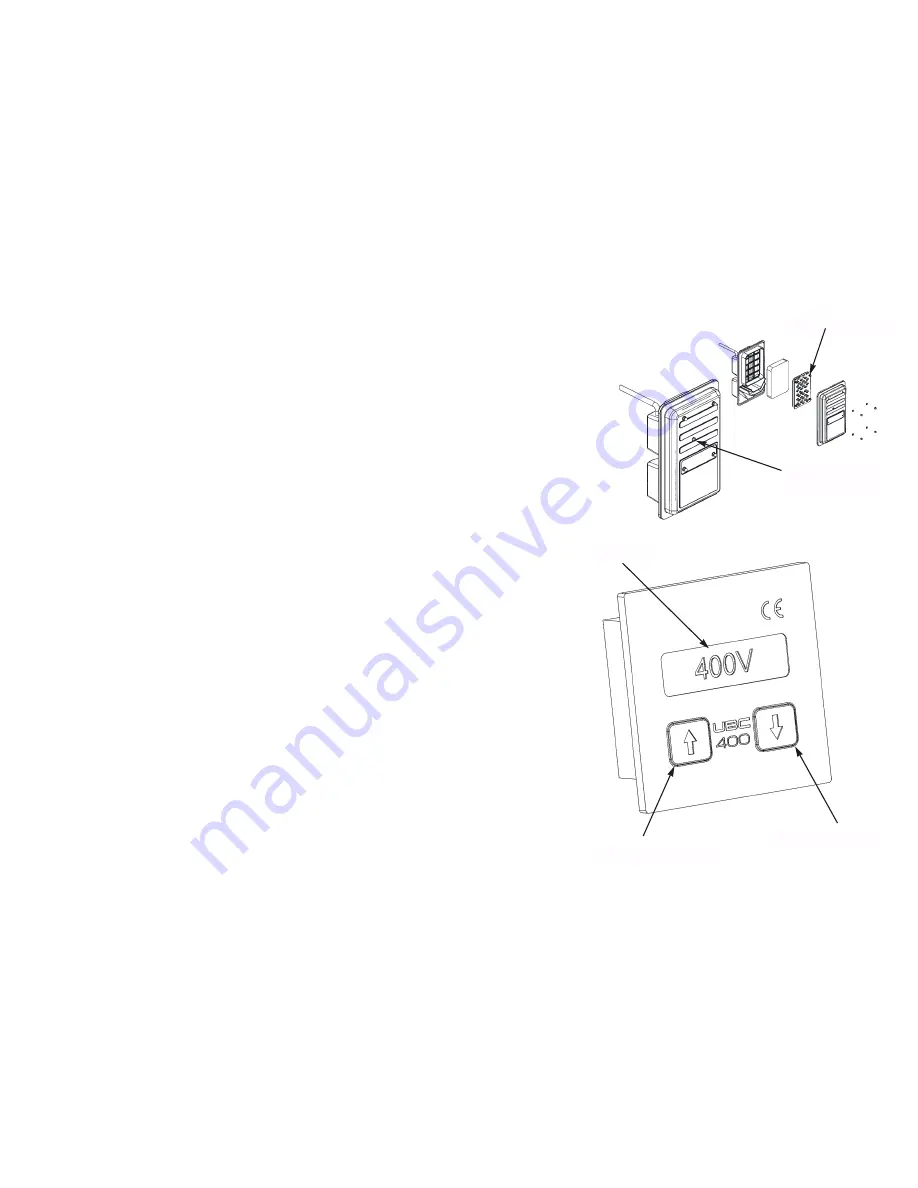

Key for moving upwards

Display

Key for moving downwards

12.3 Universal built-in controller UBC 400 (option)

It provides the display of 20 current parameters of the electric plant, which were not displayed

earlier.

Due to the application of the microprocessor measuring system, UBC is made in the form of a

Geko compact module, and the controller UBC 400 can be mounted in most Geko electric

plants.

It is applied for both one- and three-phase electric plants.

• Voltage

N - L1, N - L2, N - L3

• Voltage

L1 - L2, L2 - L3, L3 - L1

• Current L1,

L2, L3

• Total current

• Frequency

• Power per Phase in kVA

L1, L2,

L3

• Total power in kVA

• Running time

• Maintenance periodicity 100 + 300 Std.

• Real time and date

All data are transformed by a high-efficiency measuring amplifier to digital signals. The latter sig-

nals are processed by a microprocessor. The parameter is chosen by arrow keys.

Change of the parameters of maintenance periodicity, the calibrations of voltage and current,

and the reset of the operating hours counter can be made only by our authorized representative.

See also electrical connection schemes 100122 and 100123.

Indicator of air heater

work

Resistive heating element

12.2 Air heater LVH 25 (option)

It can be applied to all engines Honda-Super Silent GX 270 and GX 390. It prevents the icing of the carburetor at low temperatures,

which allows the reliable exploitation of the electric plant under extreme conditions.

Inlet air is heated by an automatic electric resistive heater controlled by a gauge. The mode is initiated by a light-emitting diode on

the casing of the air filter.

The heater is turned on at +10°C, because the icing of the carburetor often begins already at temperature from 0°C to + 5°C.

See also electrical connection scheme 100127.

Summary of Contents for 4401 E -AA/HEBA

Page 2: ...2...