7

In closed buildings, it is necessary to provide the free supply (danger of the overheating damage of the plant) and removal (poisoning danger) of air. A building should be clean, dry, and protected from

dust. It must not be used to store inflammable materials. Great attention should be paid to the removal of waste gases, because they include toxic carbon oxide. Flexible hoses for the removal of waste

gases are not usually tight, and toxic carbon oxide can leak into the building. Therefore, it is necessary to charge a corresponding specialist with the design and realization of such devices.

6. Noise

level

The device has a sound power threshold of 96 (740X: 98) dB (A). It corresponds to a sound pressure level of 70 (740X: 71) dB (A) at a distance of 10 m.

7.

Supply of electric-power consumers

The power of the electric plant should be taken into account when choosing consumers. It is necessary to involve an expert in the choice of the standard size of the electric plant.

8.

Check before start

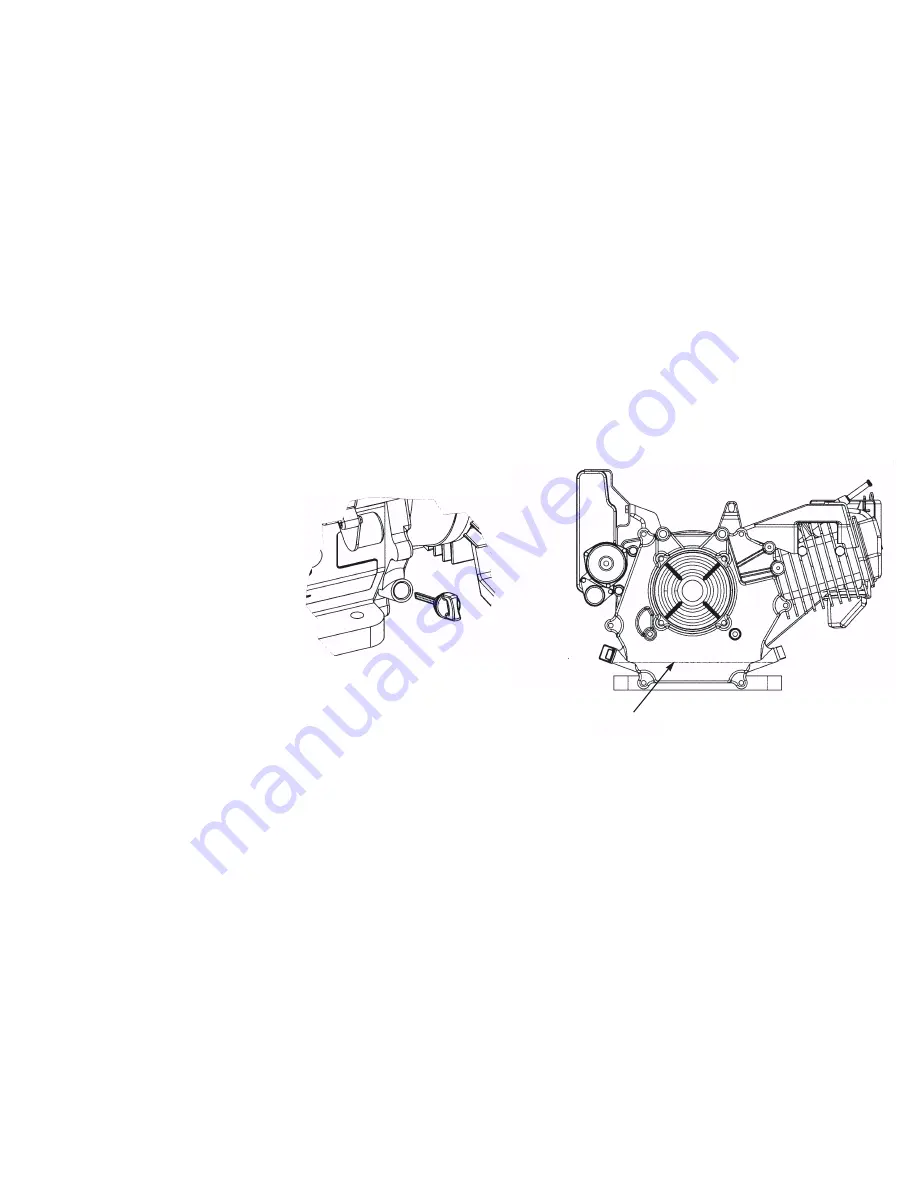

8.1 Oil level in the engine

1. Remove the plug and cleanly wipe the oil level indicator.

2. Insert the oil level indicator into the filler neck, but do not

screw.

3. If the oil level is low, it is recommended to add oil up to

the edge of the filler neck.

It is necessary to use oil for four-cycle engines that corresponds

to classes SG and SF or higher. SAE 10W-30 oil is generally

recommended for all temperatures.

8.2 Fuel

Ethyl-free car gasoline is used.

Never use a mixture of oil with gasoline or polluted gasoline.

Do not admit the hit of dirt, dust, or water into the gasoline tank.

* Gasoline is a combustible liquid and is explosive in certain cases.

* Fuel the engine only under good ventilation conditions, and the engine should be stopped during this pro-

cess. Do not smoke and do not allow the occurrence of an open flame or sparks when fueling and at fuel

storage sites.

* Do not let the overflow of fuel into the tank. After refueling, make sure that the neck cap is reliably closed.

* Watch that fuel does not spill when refueling. Gasoline vapors or spilled fuel can ignite. If gasoline spills, before the start of

the engine, make sure that the area has completely dried up, and gasoline vapors have completely disappeared.

* Avoid the contact of gasoline to skin and inhalation of gasoline vapor. Hold fuel in places inaccessible to children.

Oil level

Summary of Contents for 4401 E -AA/HEBA

Page 2: ...2...