www.gemu-group.com

28 / 33

GEMÜ 1441 cPos-X

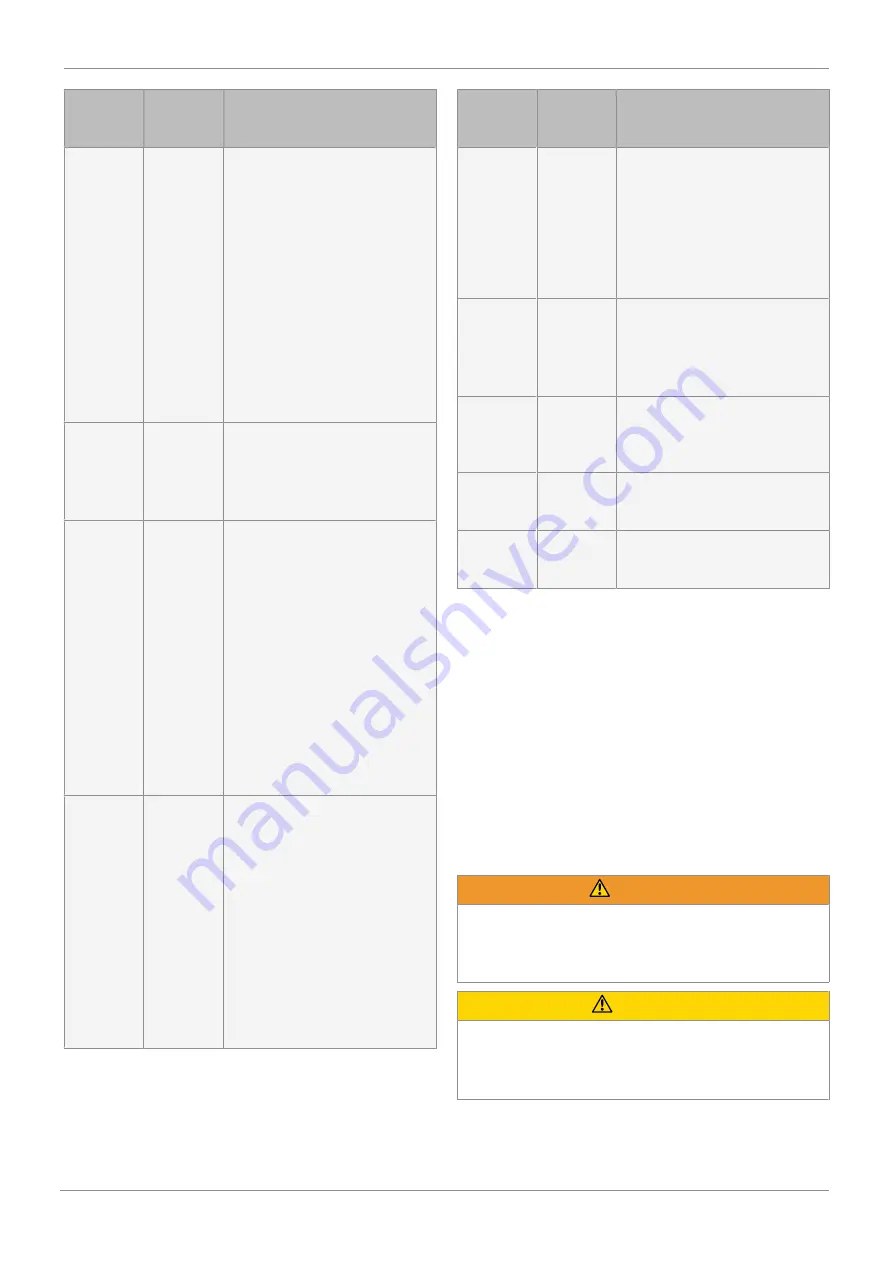

16 Inspection and maintenance

Message

ID

and type

Description

Cause and remedial measures

22

Error

Pneumatic

error

No change in the process valve

position can be detected within

the permitted time.

- Ensure that there is adequate

compressed air supply.

- Check the pneumatic connec-

tions.

- Check the pneumatic connec-

tion points.

- Check that the valve is working

correctly.

- Check the mounting kit parts

and that they are being used

correctly and in their entirety.

23

Error

Leakage

detected

A continuous change to the valve

position without any action has

been detected.

- Check the pneumatic connec-

tion points.

30

Warning

No move-

ment, or in-

correct

movement

No change in the process valve

position can be detected within

the permitted time.

- Ensure that there is adequate

compressed air supply.

- Check the pneumatic connec-

tions.

- Check the pneumatic connec-

tion points.

- Check that the valve is working

correctly.

- Check the mounting kit parts

and that they are being used

correctly and in their entirety.

60

Error

Travel

sensor error

It is no longer possible to read a

valid signal from the travel sensor.

- Check the electrical connection

for the external travel sensor.

- Ensure that the travel sensor

spindle is not pushed as far as it

will go or that it has not been re-

moved.

- Check the mounting kit parts

and that they are being used

correctly and in their entirety.

- Ensure that the mechanical as-

sembly on the valve is correct.

Message

ID

and type

Description

Cause and remedial measures

61

Warning

Button fault While starting the device, one or

both internal emergency buttons

were pressed for longer than 60

seconds.

- Check whether the housing

cover actuates the buttons or

whether the buttons are

jammed.

70

Info

Switching

cycles

alarm

threshold

reached

The set number of switching

cycles has been reached.

- If required, replace the pilot

module (then reset the switch-

ing cycle counter).

71

Info

Switching

cycle

counter re-

set

The switching cycle counter has

been reset. The message is inde-

pendently acknowledged after 30

seconds.

90

Warning

Control sys-

tem quality

restricted

The process valve cannot be

moved and therefore regulated op-

timally.

200

Warning

Warning

message

memory

Internal memory error.

- Send to GEMÜ for repair.

The behaviour of the positioner depends on the type of mes-

sage

The valve is moved to the safety position in a controlled

manner (see “Fail safe functions“, page 21). The cause of the

error must be eliminated for continued operation.

Warning:

A warning does not effect the positioner's operating

mode; however, under certain circumstances, this may not

carry out the required function. We recommend checking the

cause and, if required, eliminating it.

Info:

The status of a temporary function is displayed.

16 Inspection and maintenance

WARNING

The equipment is subject to pressure!

▶

Risk of severe injury or death.

●

Depressurize the plant.

●

Completely drain the plant.

CAUTION

Use of incorrect spare parts!

▶

Damage to the GEMÜ product.

▶

Manufacturer liability and guarantee will be void.

●

Use only genuine parts from GEMÜ.