Page 4

Introduction

Congratulations on purchasing a Gemini SA-2400 high-torque direct drive

professional turntable. This state of the art turntable includes the latest

features in modern direct drive turntable technology. Prior to use, we

suggest that you carefully read all the instructions.

Features

•

Quartz locked speed

•

+/- 10% Pitch control

•

Fully electronic braking

•

Strobe illuminator

•

Soft-touch start/stop switch

•

Platter Reverse

•

Digital Display

Precautions

1. Read all operating instructions before using this equipment.

2. The apparatus should not be exposed to dripping or splashing and no

objects filled with liquids such as vases should be placed on the

apparatus.

3. To reduce the risk of electrical shock, do not open the unit. There are

NO USER REPLACEABLE PARTS INSIDE. Please contact the Gemini

Service Department or your authorized dealer to speak to a qualified

service technician.

In the U.S.A., if you have any problems with this unit, call

1-732-969-9000 for customer service. Do not return

equipment to your dealer.

4. Tone arm bearings are factory set and sealed. Any attempt at adjust-

ment will void the warranty.

5. Be sure that all AC power is OFF while making connections.

6. Cables should be low capacitance, shielded and of proper length. Make

sure that all plugs and jacks are tight and properly connected.

7. Always begin with the audio level faders/volume controls set at

minimum and the speaker volume control(s) set to OFF. Wait 8 to 10

seconds prior to turning up the speaker volume to prevent the transient

“POP” that could result in speaker/crossover damage.

8. DO NOT EXPOSE THIS UNIT TO RAIN OR MOISTURE.

9. DO NOT USE ANY SPRAY CLEANER OR LUBRICANT ON ANY

CONTROLS OR SWITCHES.

Parts Checklist

Turntable unit.................................................................................1

Dust cover hinge............................................................................2

Turntable platter.............................................................................1

45 RPM adapter...............................................................................1

Neoprene mat....................................................................................1

Counter balance.............................................................................1

Dust cover......................................................................................1

Headshell.......................................................................................1

Assembly and Set-Up

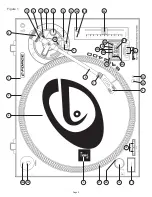

NOTE: SEE FIG. 1 (PAGE 1) FOR PART NUMBERS AND

LOCATIONS.

TURNTABLE INSTALLATION:

1. Set the TURNTABLE BASE (1) on a flat, level surface free of vibration.

Try to place the unit as far away from the speakers as possible. Keep

the unit away from direct exposure to the sun, heat, moisture or dirt.

Keep the unit well ventilated. Use the turntable feet to horizontally

stabilize the unit.

2. Make sure that the VOLTAGE SELECTOR (3) switch (located on the

TURNTABLE BASE) is set to the correct voltage. WARNING: If you try

to operate the turntable with the incorrect voltage setting, it can damage

your turntable.

3. After checking to ensure that all packing materials have been removed,

gently place the PLATTER (2) on the center spindle of the TURNTABLE

BASE (1).

4. Put the NEOPRENE MAT (4) on the PLATTER (2).

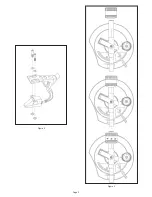

CARTRIDGE INSTALLATION: (SEE FIG. 2)

Because all cartridges have their own designs, please refer to your

particular cartridge’s instructions to insure proper installation.

1. Connect the lead wires to the cartridge terminals. For your convenience,

the terminals of most cartridges are color coded. Connect each lead

wire to the terminal of the same color.

White (L+).............................................Left C

Blue (L-)...............................................Left Channel -

Red (R+)................................................Right C

Green (R-).............................................Right Channel -

2. Mount the cartridge in the HEADSHELL (5) and tighten it with the

screws included with the cartridge.

HEADSHELL INSTALLATION:

Insert the HEADSHELL (5) into the front of the tubular TONE ARM (6).

While holding the HEADSHELL firmly in a horizontal position, turn the

LOCKING NUT (7) counter clockwise until the HEADSHELL is locked in

place. The Gemini angled headshell was designed to be used with a

straight tone arm. Any type of cartridge can be mounted in the Gemini

angled headshell.

USING A STRAIGHT TONE ARM:

When using a straight tone arm with a banana stylus or a cartridge

mounted in a standard headshell, you should always use a conical type of

needle. If you use an elliptical needle, the needle will sit in the groove of the

record properly, but one channel will be louder than the other channel.

The Gemini straight tone arm has been designed so that it will line up with

markings on LPs you have made when using a turntable with an S-shaped

tone arm.

COUNTERWEIGHT INSTALLATION: (SEE FIG. 3)

1. Slide the COUNTERWEIGHT (8) onto the rear of the TONE ARM (6)

with the numbered stylus gauge facing forward.

2. Twist the COUNTERWEIGHT (8) lightly counter clockwise, to screw it

onto the rear of the TONE ARM (6)

.

ADJUSTING HORIZONTAL ZERO (0) BALANCE AND

STYLUS PRESSURE:

1. Without touching the stylus tip, remove the stylus protector (if your

cartridge has a detachable one).

2. Release the ARM CLAMP (9) and lift the TONE ARM (6) off the ARM

REST (10).

3. Counter clockwise advancement of the COUNTERWEIGHT (8) will

cause the cartridge side of the TONE ARM (6) to be lowered. Clockwise

will cause the opposite. Turn the COUNTERWEIGHT clockwise or

counter clockwise as needed until the TONE ARM is balanced horizon-

tally. You can easily tell this by watching for the point where the TONE

ARM “floats” freely.

4. Place TONE ARM (6) on ARM REST (10) and lock it in place with the

ARM CLAMP (9).

5. With the TONE ARM (6) locked on the ARM REST (10), hold the

COUNTERWEIGHT (8) steady with one hand while rotating the

STYLUS PRESSURE RING (11) until the numeral “0” on the ring aligns

with the center line on the TONE ARM rear shaft. The horizontal zero

(0) balance should be completed.

6. Refloat the TONE ARM to ensure horizontal zero (0) balance. If zero

balance has not been maintained, repeat counterweight steps 3 - 5.

Summary of Contents for SA-2400

Page 3: ...Page3 Figure 2 Figure 3...