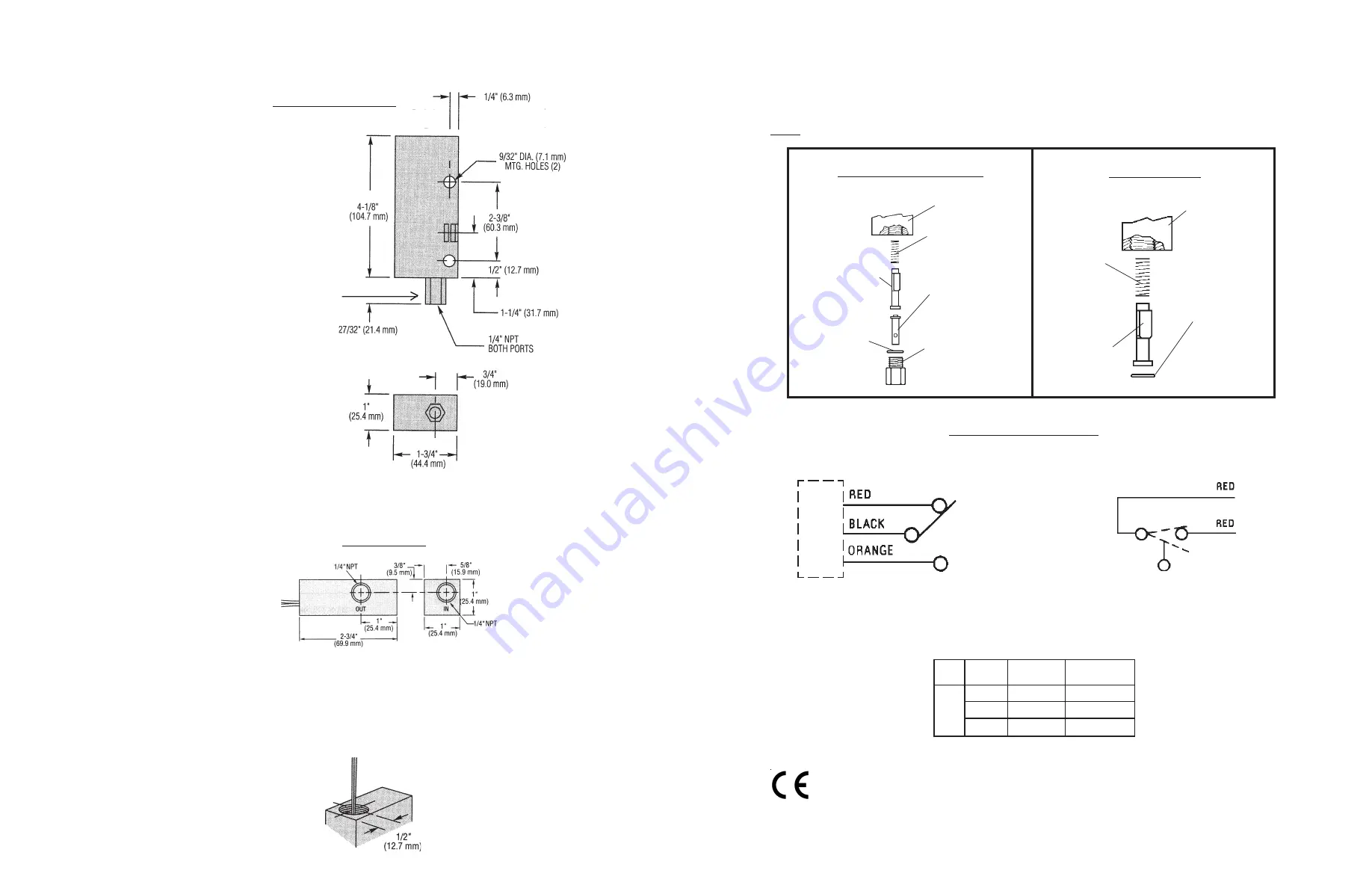

Dimensions . . .

This product is suitable for Class I and Class II applications only, per the requirements of standard EN60730 and any

additional specific requirements for a particular application or medium being sensed. Class I compliance of metal

bodied units requires a ground connection between the metal body and the earthing system of the installation. Class

I compliance of plastic bodied units in contact with a conductive medium requires that the medium be effectively

earthed so as to provide an earthed barrier between the unit and accessible areas. For Class III compliance, a supply

at safety extra-low voltage (SELV) must be provided. Please consult the Factory for compliance information on

specific part numbers.

Switch Ratings

Max. Resistive Load

VA

20

Volts

0-30

120

240

Amps DC

.3

.13

.06

Amps AC

.4

.17

.08

Typical Wiring Diagrams

FS-927 Series

FS-925, FS-926, FS-930 Series

A

C

B

Pin Connections for

Units with MS Receptacle

FS-925/926/930 Series

Piston

Inlet

Fitting

Housing

Spring

Low Flow Piston

(FS-926 ONLY)

O-Ring

FS-927 Series

Housing

Spring

Retainer

Ring

Piston

Accumulation of foreign debris should periodically be removed from these switches. Occasional "wipe-

down" cleaning when excessive contamination is present is all that is normally required. To clean: Remove

unit from system and disassemble as shown below. Clean all parts, reassemble and reinstall unit.

Note:

50 micron filtration is recommended.

Maintenance . . .

FS-927 Series

Electrical Connection

(1/2" NPT Conduit)

(FS-925/FS-930)

(FS-926) 1-9/32" (32.5mm)

FS-925/926/930 Series

For FS-926 the inlet fitting it torqued at the factory. Hold

fitting hex with wrench at installation to prevent additional

accumulation torque which could cause sensor malfunction.