Warrick

®

Series 2800 Seal Leakage Detector

Installation and Operation Bulletin

P/N 100504-1

Rev. B

This bulletin should be used by experienced personnel as a guide to the installation of Series 2800 controls. Selection or

installation of equipment should always be accompanied by competent technical assistance. We encourage you to

contact Gems Sensors Inc. or its representative if further information is required.

Specifications

Contact Design: 2PST and 3PST bridge type double break in

all possible combinations of normally open and normally

closed. Fully enclosed. Buttons are 1/4 inch diameter silver

cadmium oxide.

Contact Rating: 16A @ 115 VAC, 8A @ 230VAC, 1 H.P. @

115, 230 VAC

Mode of Operation: Direct only. Contacts assume normal

position with open circuit.

Supply Voltage: 115, 230, 406 or 575 VAC models: +10% -

15%, 50/60 Hz

Supply Current: Relay energized 4.4 VA

Secondary Circuit: 500 VAC on probes, 6 VA with short

circuited electrode circuit

Sensitivity: 20K Ohms/cm (150’ maximum distance between

control and probes).

Temperature: -40° to 150°, ambient

Terminals: Size 8 pan head screws with wire clamping plate

for use with captivated wires or a maximum of 1-#12 AWG/2-

#14 AWG uncaptivated wires. Numbered 1 to 10 for identifica-

tion. Located on front of control assembly for accessibility.

Listings: UL limit control recognized (353) on open type

controls only.

General

The Type 2800 is a conductance-actuated control for detection

of moisture in the oil chamber of a submersible motor. It is

used as a warning device to indicate a seal leakage and to

signal the need for preventative maintenance.

Installation

Mount the control or enclosure vertically on wall or other solid

structure, with the transformer on the left-hand side. Wire

Series 2800 as indicated on drawing. Terminals on the control

are numbered and are in the same relative position as shown

on the wiring diagram. Terminal pair 1 and 2 must be continu-

ously energized from an AC supply line of electrical character-

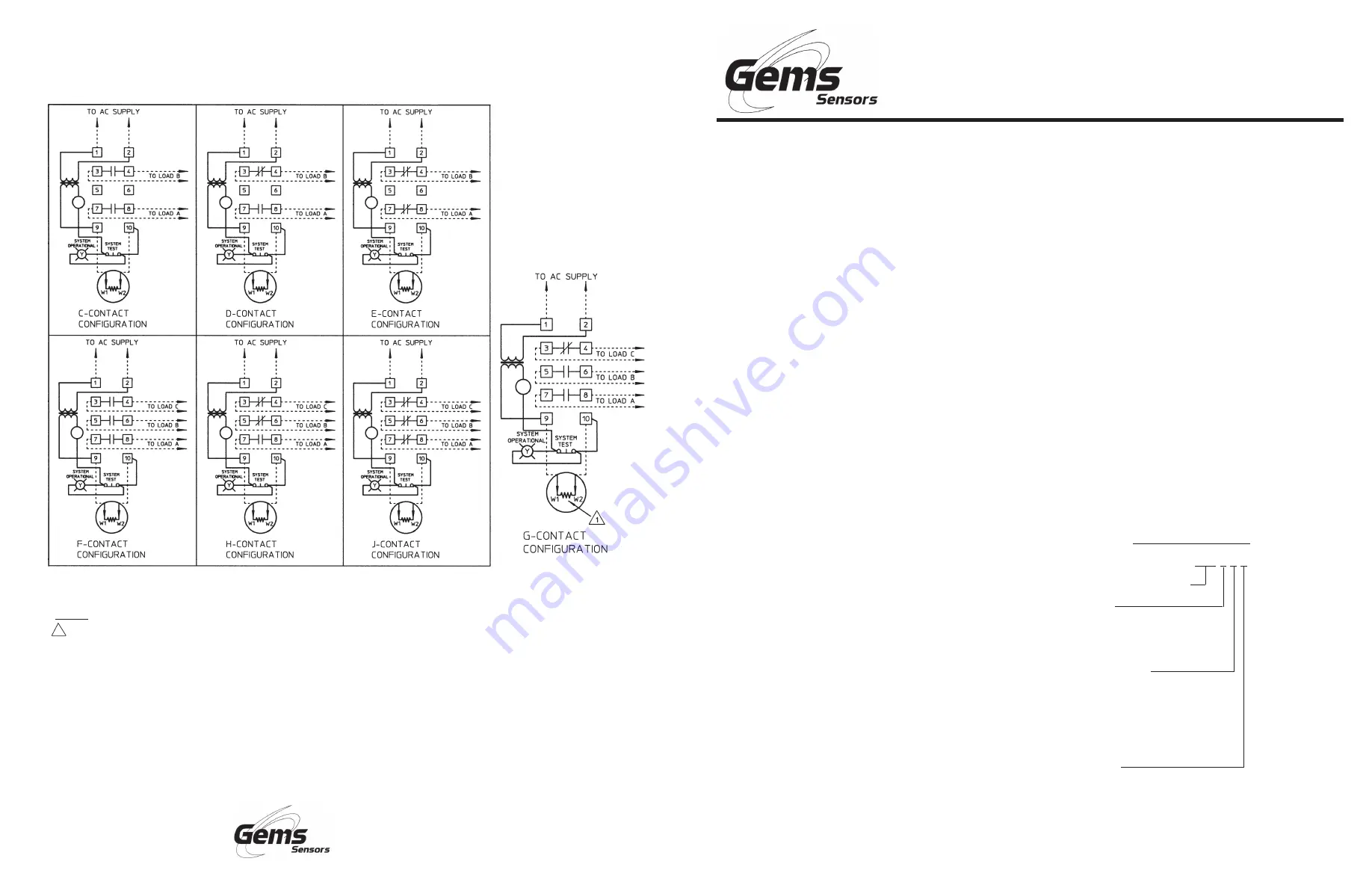

istics shown on the data plate. Contacts 3-4, 5-6 and 7-8 are

available for load duty and, if required, must be wired in series

with the load device(s) and load. Terminals 9 and 10 connect

to the moisture sensing probes in the motor marked W1 and

W2 via cable provided with the motor.

Caution: Probe Sensing circuit, terminals 9 and 10, have 500

VAC, 12mA. This high voltage has minimal amperage, but can

cause significant shocking.

Operation

Normally the oil surrounding the probes is nonconductive and

the control will be de-energized. An influx of moisture past the

outer seal and into the oil reservoir will change the conductivity

of the oil and cause the relay to energize. Note that the

moisture may not cause this change in conductivity until

motor is running and the moisture becomes emulsified

Operation

(Cont.)

with the oil. Load contacts 3-4, 5-6 and 7-8 will change from

their normally open or normally closed position when the control

energizes.

Test Procedure

A normally closed push-button and neon indicating lamp are

provided as part of the control for testing the moisture sensing

components. The motor manufacturer has provided a 330,000-

ohm resistor across the probes inside the motor to complete the

test. When the test push-button is depressed, the neon

indicating lamp will be illuminated to indicate:

A. Power is supplied to the control

B. The control is operative

C. Wiring to the moisture-sensing probes in the

motor are intact

This check does not simulate a seal leakage.

To simulate a seal leakage the following test should be

done. Caution: Voltage will be present at all terminals on the

control when this test is being made:

Remove the enclosure cover and momentarily place an insu-

lated jumper (or 20K ohm resistor) across terminals 9 and 10

on the control. The control should energize, simulating a leak

condition.

Wire control per drawing, following NEC and local codes. Use

appropriately sized spade terminals when wiring.

Ordering Information

Model 2800 X X X Moisture Detectors

Basic Model of Moisture Relays

Supply Voltage

1) 115 VAC

2) 230 VAC

4) 460 VAC

5) 575 VAC

Contact Configuration

C) 2 N.O. & 0 N.C.

D) 1 N.O. & 1 N.C.

E) 0 N.O. & 2 N.C.

F) 3 N.O. & 0 N.C.

G) 2 N.O. & 1 N.C.

H) 1 N.O. & 2 N.C.

J) 0 N.O. & 3 N.C.

Enclosure Type

0) Open - No Enclosure

1) NEMA 1

4) NEMA 4

Gems Sensors Inc.

One Cowles Road

Plainville, CT 06062-1198

Tel: 860-793-4579

Fax: 860-793-4580

Wiring Diagrams

Notes:

1. Resistor internal to the submersible motor (330K ohms)

2. Dashed lines represent field connections

3. Open version only is UL recognized (UL 353 File: MP1430)