Genebre Building. Av. de Joan Carles I, 46-48

08908 L'Hospitalet de Llobregat. Barcelona (Spain)

genebre@genebre.es - www.genebre.es

GENEBRE S.A.

UPDATE DATE: 07/07/2020 UPDATE NUMBER: 1

8

8. Starting Up (Settings)

Note: The positioner leaves the factory set to position 0º and path 90º. In case you

need to establish these settings, proceed as follows.

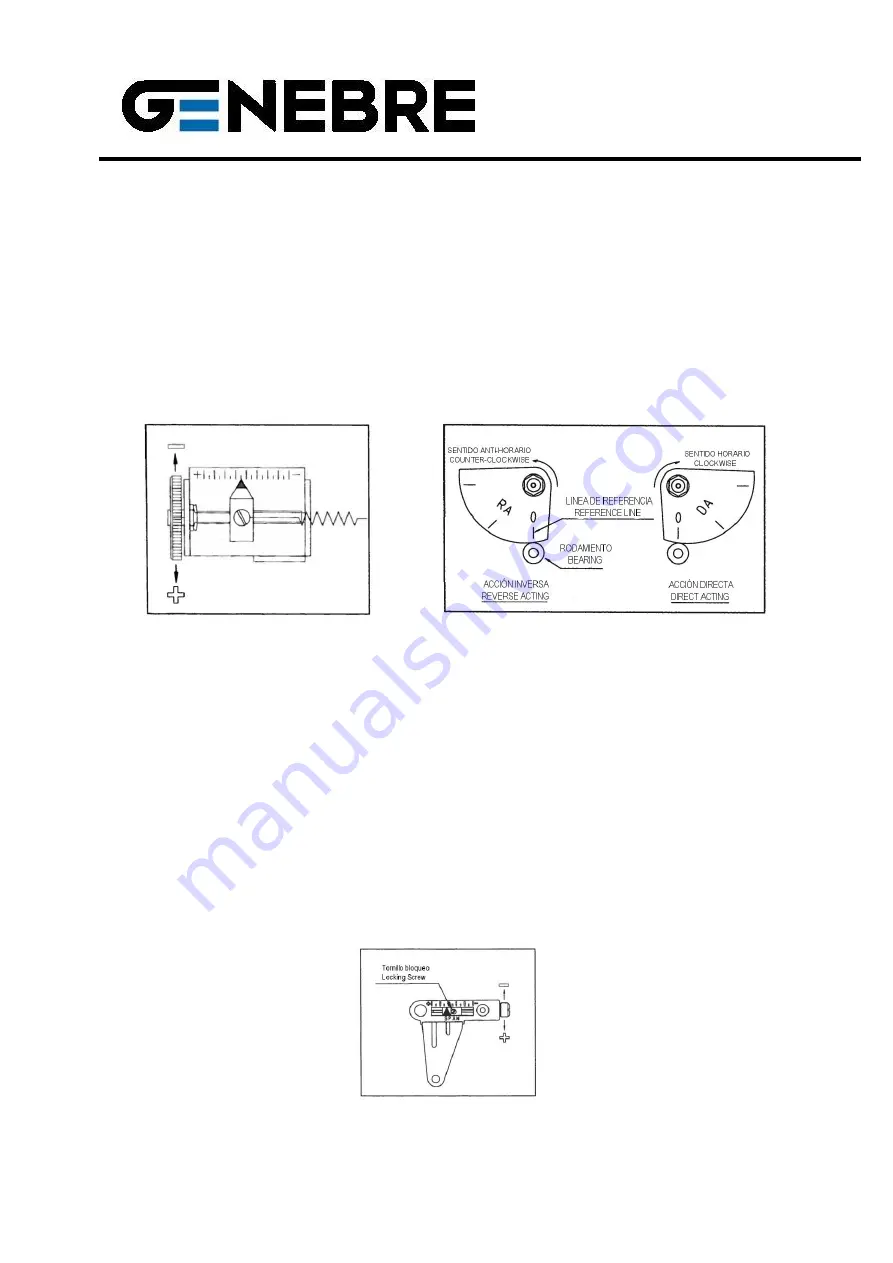

8.1 Zero Setting

•

Send a run start signal (3 PSI).

•

Turn the ZERO setting wheel clockwise or counter-clockwise until the reference

lines of the indicator cam and the tangent point of the bearing match.

ZERO

•

In the case of the single effect actuator, check that it is set to zero point at

standard pressure. Otherwise, repeat Zero Setting.

8.2 Span Setting

•

Set the span so that the actuator stops at position 0% in the run with an input

signal of 0% (3 PSI), and so that it stops at position 100% with an input signal of

100% (15 PSI), respectively.

•

Check Zero point and repeat the Span setting as many times as required.

•

Once the equipment is set, tighten the Locking screw.