Remove the four cor ner screws of the

DCW (use a 4 mm Allen key) and pull the

plate care ful ly out with out stress ing the

wires and the gas ket. Rotate the plate 90

degrees in the ap pro pri ate di rec tion and

re mount the screws.

Flush mounting

The 1038BC can be used flush mounted

into the control room wall, which offers

some acoustical benefits. No cabinet

edge diffraction will occur, resulting in an

improved response, especially at mid-

range frequencies. Low frequency reflec-

tions from the wall behind the speaker

can be avoided, which improves the low

frequency response and efficiency and

allows the speaker to work in half space

conditions. In terms of installation and

orientation, the speaker’s acoustical axis

(See figure 1) should point directly to the

listening position. The speaker should be

vertically aimed so that the acoustical axis

of the two speakers meet midway between

the standing and seated listening position

(1.4 m - 4’7” from the floor). In the horizon-

tal plane the speaker should be positioned

according to the standard stereophonic

(60 degrees between left-right channels)

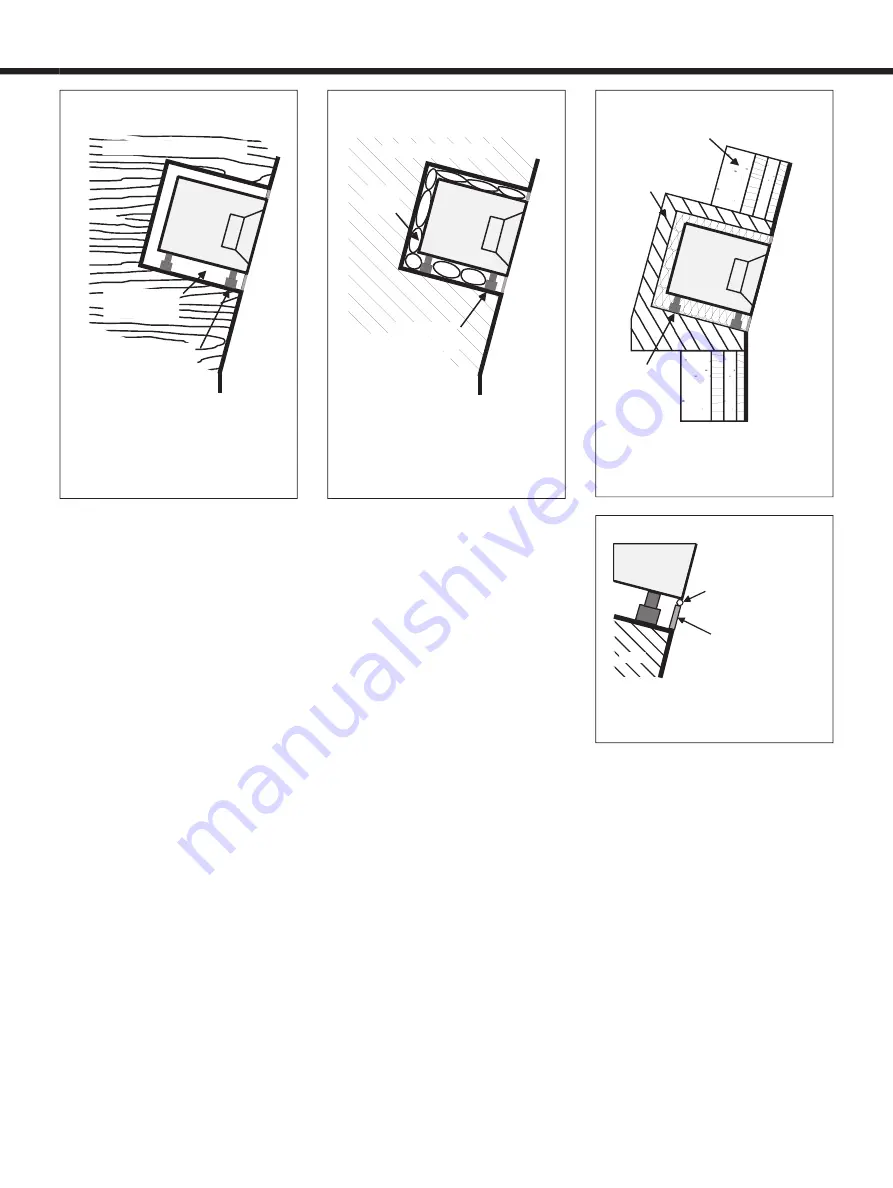

Figure 4: Flush mounting the speaker in a

wall constructed of wood

Figure 5: Flush mounting the speaker in a

wall constructed of concrete

Figure 6: Flush mounting the speaker in

a wall constructed of a combination of

materials.

FACING PANEL

FIXED TO THE WALL

(50-100 mm / 2-4")

RUBBER GASKET

(5-10 mm / ¼-½")

SPEAKER

WALL

Figure 7: Covering the gap between the

wall and the speaker cabinet.

or multichannel (ITU-R BS.775-1) place-

ment recommendation.

The ceiling, side walls and especially the

rear wall should be acoustically absorbent

at low frequencies. The wall in which the

speakers are mounted should have a high

acoustical mass to properly implement half

space radiation at low frequencies and be

angled so that the speakers are correctly

aimed. However, the speakers should not

be mounted too high as this increases the

required vertical tilt of the speaker (maxi-

mum tilt angle < 20 degrees) and reduces

the optimum listening area. Great care

should be taken over how the speaker is

mounted into the wall. Note the following:

A space 50 to 100 mm (2 to 4”) wide can

be left around the speaker. Cover the space

around the speaker with a facing panel that

should be fixed to the wall. Leave a gap of

about 5 to 10 mm (¼ to ½”) between the

speaker and the panel. Fill this gap with

a soft rubber gasket to allow for possible

cabinet movement (see figure 6).

Ensure that the speaker cables can

reach the rear of the speaker cabinets.

Regardless of the type of front wall

construction the speaker cabinet should

be mounted on vibration isolators, with a

resonant frequency of 2 to 8 Hz, to pre-

vent vibrations from being transmitted to

the wall and impairing the low frequency

performance.

If a heavy wooden front wall construc-

tion is used, the space around the cabinet

should be filled with absorbent mineral wool

or foam plastic. The wooden wall structure

must be heavily braced to achieve suf-

ficiently high mass and rigidity (see figure

4).

In a solid wall (e.g. concrete) structure,

the space around the cabinet should be

filled with either absorbent mineral wool or

sand bags (see figure 5).

The wall can also be constructed of a

combination of materials to achieve high

CONCRETE

STRUCTURE

VIBRATION

ISOLATORS

f ~ 2-8 Hz

MULTI-LAYERED WALL

(WOOD, CONCRETE, BRICKS)

VIBRATION

ISOLATORS

f ~ 2-8 Hz

CONCRETE WALL

SAND

BAGS

VIBRATION

ISOLATORS

f ~ 2-8 Hz

HEAVY WOODEN WALL

ABSORBING

MATERIAL