Operation

17973 G

MLT6SM/K-8SK Operating Manual

21

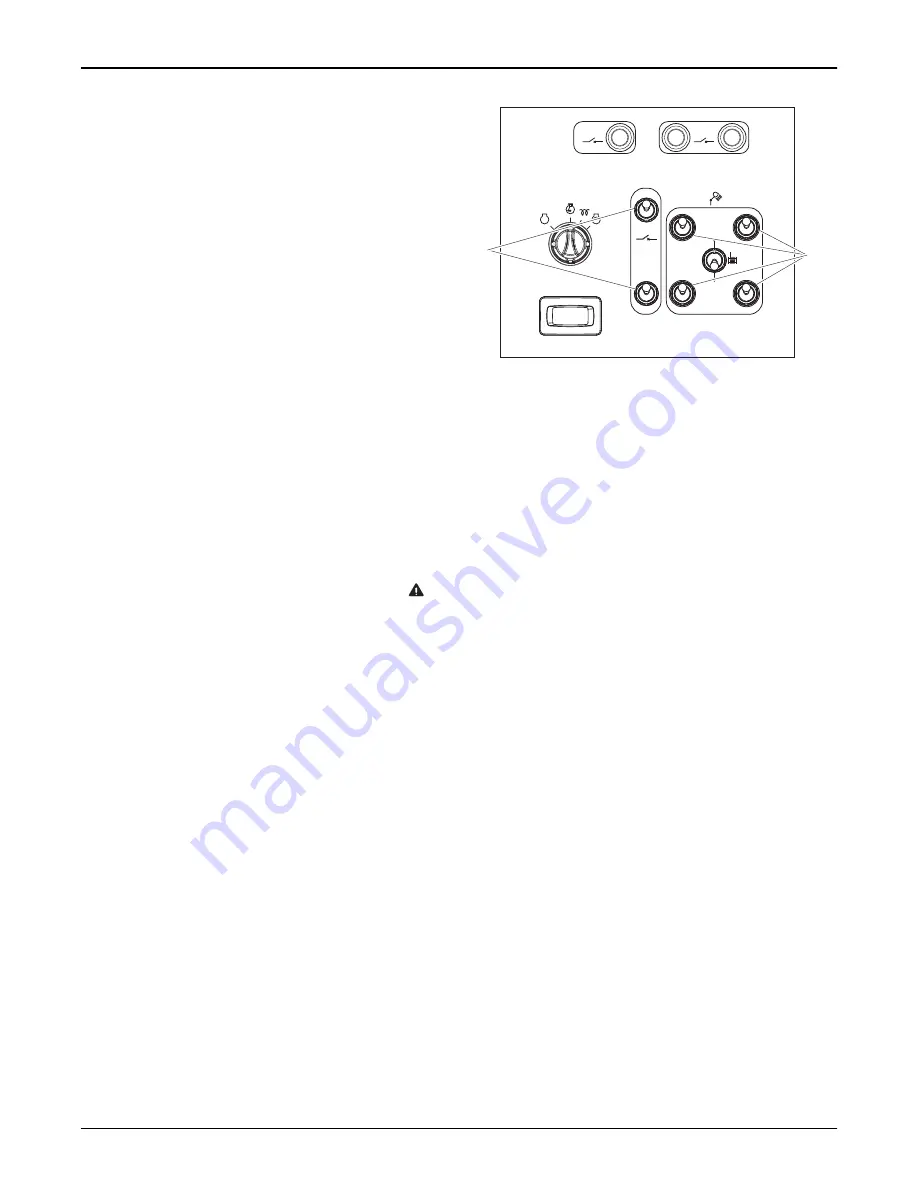

1. Once the engine is up to temperature and running

smoothly, switch the main circuit breaker (A) to

the ON (I) position.

2. With the main circuit breaker on, switch each

individual circuit breaker for the lights (B) to the

ON (I) position, one at a time.

3. The ballast indicator lights (C) will come on and

continue to get brighter as the lights warm up,

and then remain on. This confirms that power is

coming from the ballasts to the lights.

4. If an indicator light does not come on, the ballast

may need to be serviced. If the indicator light

comes on and stays lit, but the related light is not

illuminated, check the bulb or the mast wiring.

Refer to

“Troubleshooting the Lights” on

page 33.

Figure 12 - Light Switches and Breakers

5. The lights require a warm up period of 5-15 minutes before they reach full output. If the lights are shut down,

they require a cool down period of approximately 10 minutes before they can be switched on again.

6. The light tower uses four 1000W bulbs. When checking or replacing the bulbs, wipe them with a clean cloth

to avoid leaving any grease, oil residue or fingerprints on the glass. Any residue can create a hot spot on

the bulb, causing premature bulb failure.

CAUTION

Bulbs become extremely hot when in use. Allow bulb fixture to cool 10-15 minutes before

handling or lowering the mast.

DERATING FOR ALTITUDE

All units are subject to derating for altitude and temperature; this will reduce the available power for operating tools

and accessories connected to the receptacles. Typical reductions in performance are 2-4% for every 1000 ft (305

m) of elevation and 1% per 10ºF (5.6ºC) increase in ambient air temperature over 72ºF (22ºC).

WET STACKING

The unit is powered by a diesel engine. Diesel engines are susceptible to wet stacking if lightly loaded. Wet stacking

occurs when an engine is run at less than 30% of its full load capacity, causing unburned fuel to accumulate in the

exhaust system. Wet stacking can be detected by continuous black exhaust when the unit is under a constant load.

It can also cause fouling of injectors and buildup on engine valves. Diesel engines operate properly when applied

loads are between 30% and 100% capacity. Appropriate generator sizing is determined by the anticipated load. If

the unit is in a wet stack condition, load the unit heavily for five hours or until the exhaust is clear.

00761

A

I

O

I

O

I

O

I

O

MAIN

BREAKER

240V

I

O

STOP

15 SEC.

MAX.

I

O

12V

DC CIRCUIT

BREAKER

AC CIRCUIT

BREAKERS

120V

B

Summary of Contents for MLT6SK

Page 4: ...iv This Page Intentionally Left Blank ...

Page 12: ...Safety 6 MLT6SM K 8SK Operating Manual 17973 G This Page Intentionally Left Blank ...

Page 32: ...Operation 26 MLT6SM K 8SK Operating Manual 17973 G This Page Intentionally Left Blank ...

Page 34: ...Maintenance 32 MLT6SM K 8SK Operating Manual 17973 G This Page Intentionally Left Blank ...

Page 36: ......