Generac Portable Products 2200 PSI High Pressure Washer

12

GENERAL MAINTENANCE

RECOMMENDATIONS

The warranty of the high pressure washer does not

cover items that have been subjected to operator

abuse or negligence. To receive the full value from

the warranty, the operator must maintain the high

pressure washer as instructed in this manual.

Some adjustments will need to be made

periodically to properly maintain your high pressure

washer.

All adjustments in the Service and Adjustments

section of this manual should be made at least

once each season.

Once a year you should clean or replace the spark

plug and clean or replace the air filter and check

the gun and wand assembly for wear. A new spark

plug and clean air filter assure proper fuelair

mixture and help your engine run better and last

longer.

Before Each Use

Check engine oil level.

Check water inlet screen for damage.

Check high pressure hose for leaks.

Check chemical injection tube and filter for

damage.

Check gun and nozzle extension assembly for

leaks.

Rinse out garden hose to flush out debris.

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine the screen on the water inlet. Clean it if the

screen is clogged or replace it if screen is damaged.

Check High Pressure Hose

The high pressure hose can develop leaks from

wear, kinking, or abuse. Inspect the hose each time

before using it. Check for cuts, leaks, abrasions or

bulging of cover, damage or movement of couplings.

If any of these conditions exist, replace the hose

immediately.

DANGER!

Water spraying from a leak is

capable of injecting material into skin. Inspect

hose each time before using it. Never repair a

high pressure hose. Replace it with another

hose that meets the maximum pressure rating

of your pressure washer.

Check Chemical Injection Tube

Examine the filter on the detergent hose and clean if

clogged. The tube should fit tightly on the barbed

fitting. Examine the tube for leaks or tears. Replace

the filter or tube if either is damaged.

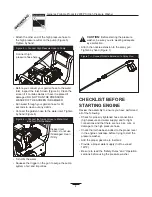

Check In-Line Filter

Refer to Figure 12 and service the in-line filter if it

becomes clogged, as follows:

1. Detach gun and lance from high pressure hose.

Detach lance from gun and remove o-ring and

screen from lance. Flush the screen, gun, and

lance with clean water to clear debris.

2. If the screen is damaged, the o-ring kit contains a

replacement in-line filter screen and an o-ring. If

undamaged, reuse screen.

3. Place the in-line filter screen into the threaded

end of the lance. Direction does not matter. Push

the screen in with the eraser end of a pencil until

it rests flat at the bottom of the opening. Take

care to not bend the screen.

4. Place the o-ring into the recess. Push the o-ring

snugly against the in-line filter screen.

5. Assemble the lance to the spray gun, as

described earlier in this manual.

Figure 12 Clean In-Line Filter

Lance

Filter Screen

O-ring