Generac Portable Products 2,400 PSI High Pressure Washer

15

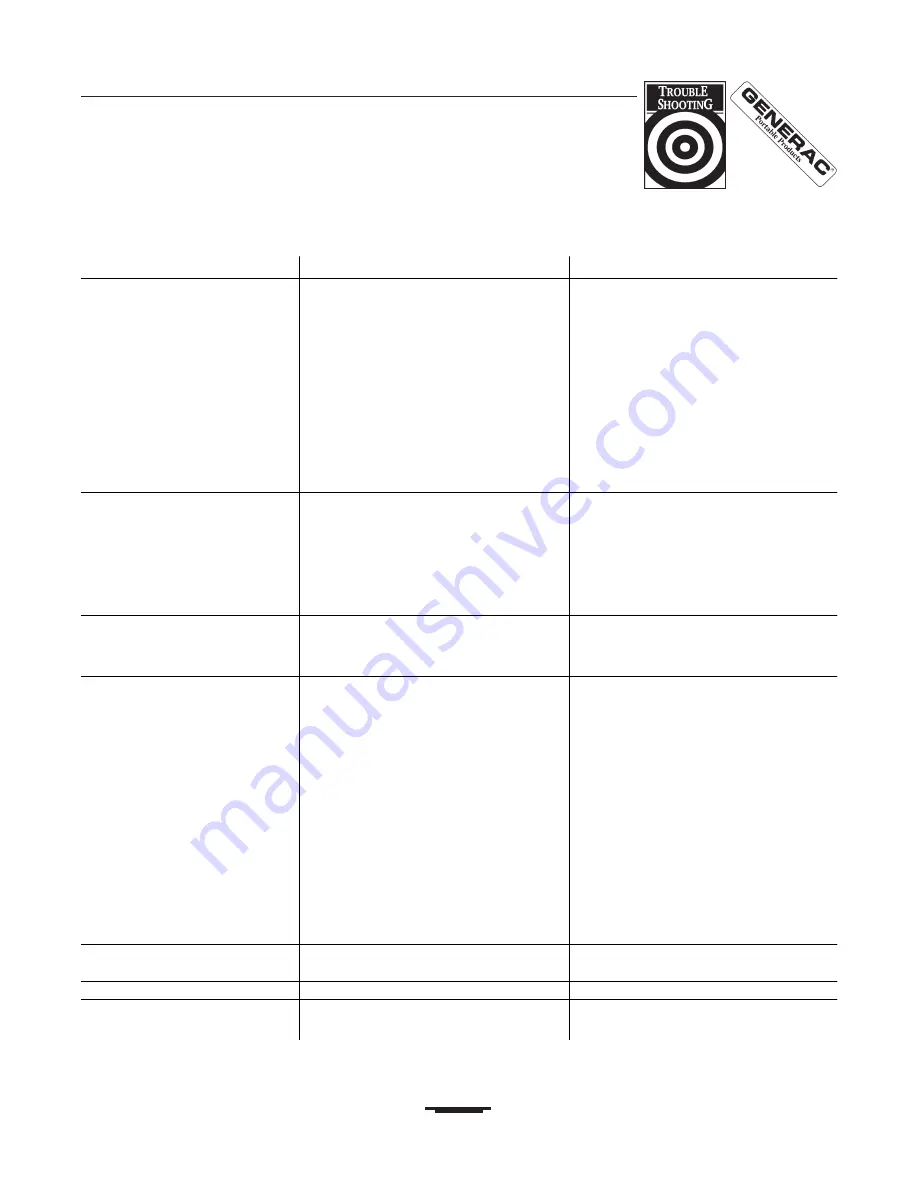

TROUBLESHOOTING

Problem

Cause

Correction

Pump has following

problems: failure to produce

pressure, erratic pressure,

chattering, loss of pressure,

low water volume.

1.

Nozzle in low pressure mode.

2.

Water inlet is blocked.

3.

Inadequate water supply.

4.

Inlet hose is kinked or leaking.

5.

Clogged inlet hose strainer.

6.

Water supply is over 100°F.

7.

High pressure hose is blocked or

leaks.

8.

Gun leaks.

9.

Nozzle is obstructed.

10.

Pump is faulty.

1.

Pull nozzle backward for high

pressure mode.

2.

Clear inlet.

3.

Provide adequate water flow.

4.

Straighten inlet hose, patch leak.

5.

Check and clean inlet hose strainer.

6.

Provide cooler water supply.

7.

Clear blocks in outlet hose.

8.

Replace gun.

9.

Clean nozzle.

10.

Contact Generac service facility.

Detergent fails to mix with

spray.

1.

Detergent siphoning tube is not

submerged.

2.

Chemical filter is clogged.

3.

Dirty in-line filter.

4.

Nozzle is in high pressure mode.

1.

Insert detergent siphoning tube into

detergent.

2.

Clean or replace filter/detergent

siphoning tube.

3.

See “Check In-Line Filter” on page 12.

4.

Push nozzle forward for low pressure

mode.

Engine runs good at no-load

but “bogs” when load is

added.

Engine speed is too slow.

Move throttle control to FAST position. If

engine still “bogs down”, contact Briggs

and Stratton service facility.

Engine will not start; or

starts and runs rough.

1.

Low oil level.

2.

Dirty air cleaner.

3.

Out of gasoline.

4.

Stale gasoline.

5.

Spark plug wire not connected to

spark plug.

6.

Bad spark plug.

7.

Water in gasoline.

8.

Overchoking.

9.

Excessively rich fuel mixture.

10.

Intake valve stuck open or closed.

11.

Engine has lost compression.

1.

Fill crankcase to proper level.

2.

Clean or replace air cleaner.

3.

Fill fuel tank.

4.

Drain gas tank; fill with fresh fuel.

5.

Connect wire to spark plug.

6.

Replace spark plug.

7.

Drain gas tank; fill with fresh fuel.

8.

Open choke fully and crank engine.

9.

Contact Briggs and Stratton service

facility.

10.

Contact Briggs and Stratton service

facility.

11.

Contact Briggs and Stratton service

facility.

Engine shuts down during

operation.

1.

Out of gasoline.

2.

Low oil level.

1.

Fill fuel tank.

2.

Fill crankcase to proper level.

Engine lacks power.

Dirty air filter.

Replace air filter.

Engine “hunts” or falters.

Choke is opened too soon.

Move choke to halfway position until

engine runs smoothly.