12

Generac Portable Products 2700PSI High Pressure Washer

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for 3-5

minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach a

temperature between 140145°F. When the water

reaches this temperature, the automatic cool down

system engages and cools the pump by

discharging

the warm water onto the ground.

This system

prevents internal damage to the pump.

GENERAL MAINTENANCE

RECOMMENDATIONS

The warranty of the high pressure washer does not

cover items that have been subjected to operator

abuse or negligence. To receive full value from the

warranty, operator must maintain high pressure

washer as instructed in this manual.

Some adjustments will need to be made

periodically to properly maintain your high pressure

washer.

All adjustments in the Service and Adjustments

section of the engine owners manual should be

made at least once each season.

Once a year you should clean or replace the spark

plug, clean or replace the air filter and check the

gun and wand assembly for wear. A new spark plug

and clean air filter assure proper fuel-air mixture

and help your engine run better and last longer.

BEFORE EACH USE

Check engine oil level.

Check water inlet screen for damage.

Check high pressure hose for leaks.

Check detergent inlet hose and filter for damage.

Check gun and wand assembly for leaks.

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine screen on the water inlet. Clean if the

screen is clogged or replace if screen is damaged.

Check High Pressure Hose

The high pressure hose can develop leaks from wear,

kinking, or abuse. Inspect hose each time before

using it. Check for cuts, leaks, abrasions or bulging of

cover, damage or movement of couplings. If any of

these conditions exist, replace hose immediately.

DANGER

! Water spraying from a leak is

capable of injecting material into skin. Inspect

hose each time before using it. Never repair a

high pressure hose. Replace it with another

hose that meets the maximum pressure rating

of your pressure washer.

Check Gun and Wand

Examine hose connection to gun and make sure it is

secure. Test trigger by pressing it and making sure it

springs back into place when you release it. Put

safety latch in

on

position and test trigger. You should

not be able to press trigger.

Check In-Line Filter

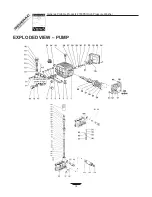

Refer to Figure 13 and service the in-line filter if it

becomes clogged, as follows:

1.Detach gun and lance from high pressure hose.

Detach lance from gun and remove o-ring and

screen from lance. Flush the screen, gun and lance

with clean water to clear debris.

Figure 13 In-Line Filter Assembly.

Lance

In-line Filter

O-ring