Owner’s Manual for 10 Ton Kinetic Splitter

15

Maintenance

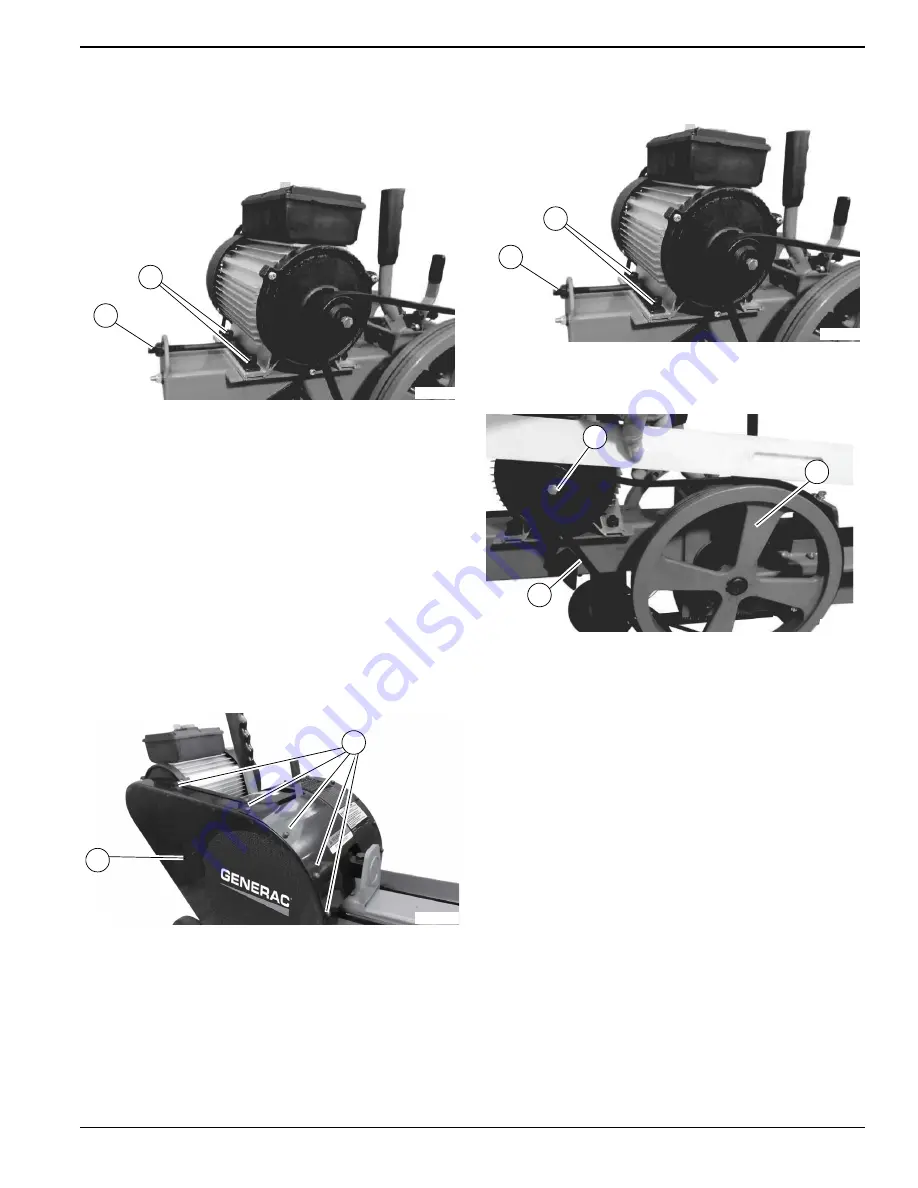

5.

See

. Loosen motor hardware (E) using

a 14 mm wrench on the bolt and a 17 mm wrench

on the nut.

6.

Use a 17mm wrench to turn tension nut (F) in

against the frame to tighten if belt is too loose or

out to loosen if belt is too tight.

010735

F

E

Figure 4-7. Adjusting Belt Tension (3 of 3)

NOTE:

The belt performs best with a slight amount of

slack to allow the belt to slip on the pulley when the

wedge encounters a tough log. Too much tension may

stall the Motor.

7.

When the belt is at the proper tension, tighten the

Motor Hardware.

8.

Reinstall the guards.

Replacing the Belt

1.

See

. Use a screwdriver to remove the

11 guard screws, washers, and lock washers (A)

that secure the center guard (B).

2.

Remove the guard screws, washers, and locknuts

that secure the flywheel and guard.

B

010722

A

Figure 4-8. Replacing Belt (1 of 3)

3.

See

Figure 4-9

. Loosen motor hardware (C) using

a 14 mm wrench on the bolt and a 17 mm wrench

on the nut (D).

010735

D

C

Figure 4-9. Belt (2 of 3)

4.

See

. Install a new belt (E) onto pulley

(G) and flywheel (F).

010735

F

E

G

Figure 4-10. Replacing Belt (3 of 3)

5.

See

. Use a 17 mm wrench to tighten

the tension nut (D).

6.

Set belt tension by turning the nut in against the

frame to tighten if belt is too loose or out to loosen

if belt is too tight.

NOTE:

The belt performs best with a slight amount of

slack to allow the belt to slip on the pulley when the

wedge encounters a tough log. Too much tension may

stall the motor.

7.

Tighten the motor hardware.

8.

Reinstall the guard.