5

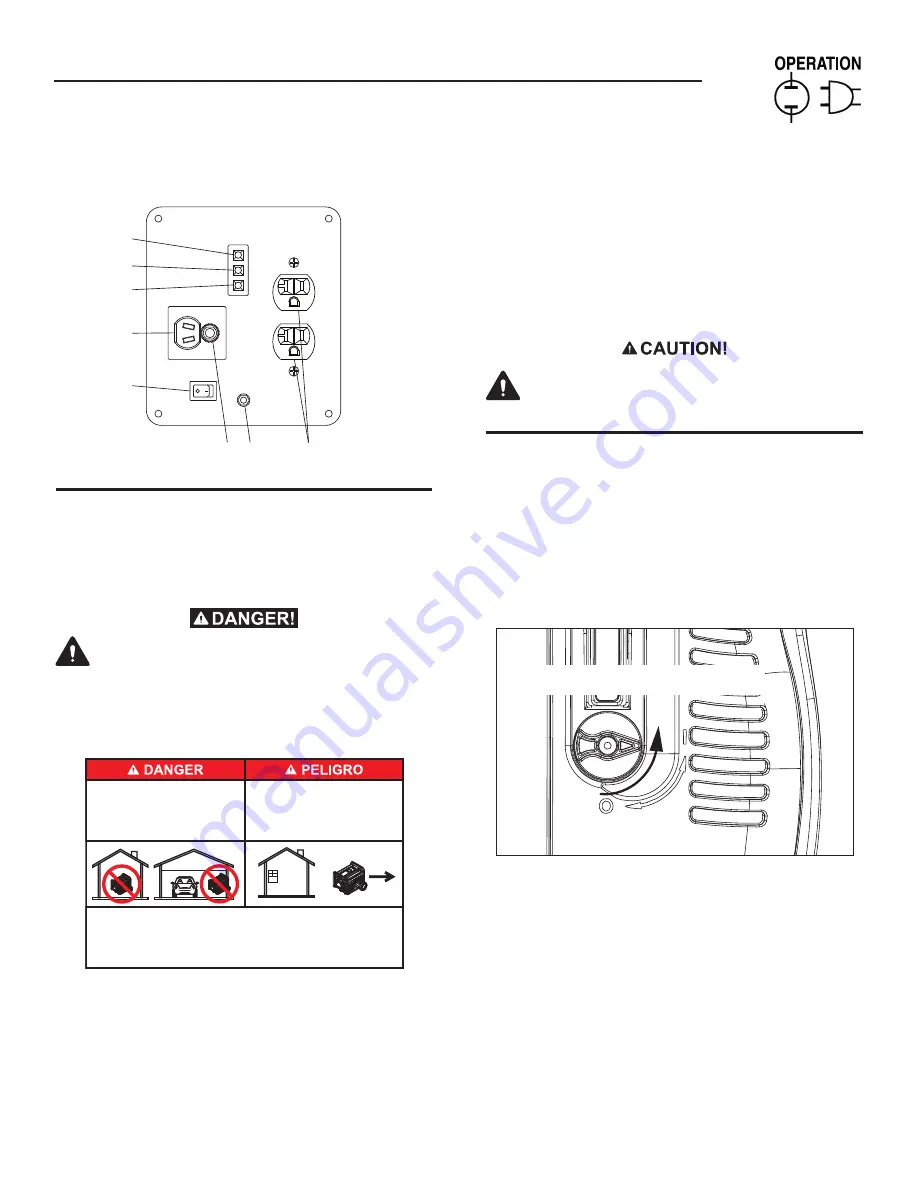

Figure 3 - Control Panel

14

15

16

17

18

19 20

21

PRE-USE CHECK

Prior to starting the generator and adding loads, perform the

following tasks:

1. Make sure the generator in on a firm, level, non-combustible

surface with at least five (5) feet of clearance on all sides.

N

ever operate in an enclosed area or indoors!

NEVER use in the home, or in partly enclosed

areas such as garages, even if doors and

windows are open! ONLY use outdoors and far

from open windows, doors, vents, and in an

area that will not accumulate deadly exhaust.

Using a generator indoors CAN KILL

YOU IN MINUTES.

Generator exhaust contains carbon

monoxide. This is a poison you

cannot see or smell.

Si usa un generador en interiores,

MORIRÁ EN POCOS MINUTOS.

El escape del generador contiene

monóxido de carbono. Es un veneno

que no tiene olor ni se puede ver.

NEVER use inside a home or garage, EVEN IF doors and windows are open.

Only use OUTSIDE and far away from windows, doors, and vents.

NUNCA lo use dentro de una casa o garaje, AUN si las puertas y ventanas

están abiertas. Sólo úselo EN EXTERIORES y lejos de ventanas, puertas y

ductos de ventilación.

2. Remove the fuel cap and check the fuel level. If fuel is needed,

see the section “FUELING THE GENERATOR”.

3. Remove the left side service cover and check the oil level by

removing the oil filler cap/dipstick. The oil level should be to

the bottom of the threads on the oil fill pipe. If oil is needed,

see the section “ADDING ENGINE OIL”.

4. Replace and secure the left side service cover.

5. Make sure there are no loads connected to the generator.

6. The National Electric Code (NEC) requires the frame and

external electrically conductive parts of the generator be

properly connected to an approved earth ground. Proper

grounding of the generator will prevent electrical shock in

the event of a ground fault condition in the generator or in

connected electrical devices. Proper grounding also helps

dissipate static electricity, which often builds up in unguarded

devices.

7. Local electrical codes may also require proper grounding of

the generator.

Starting the generator with accessories

connected to the 120 VAC outlets will damage

the generator and the connected accessories.

STARTING THE GENERATOR

Once the fuel and oil levels have been checked and it has been

verified there are no loads connected, the generator may be

started.

1. Open the fuel valve (Figure 4), located below the starter rope

pull, by turning to the valve 90° counter-clockwise to the “ON”

(I) position.

Figure 4 - Fuel Valve

TURNING THE FUEL ON

2. Pull up on the center of the fuel fill cap and prime the fuel

system by depressing the plunger until resistance is felt

(Figure 5).

3. Open the fuel tank vent on the top of the fuel fill cap by turning

the center portion to the “ON” mark.

4. If the engine is cold or has not been run for some time, engage

the choke by pushing the choke lever to the right.

5. Grip the handle for the pull starter and brace your other hand

against the generator. Pull the rope slowly until resistance is

felt, then pull the rope rapidly.

6. If the engine does not start, repeat step 4 until the engine fires

and begins to run.

Section 2 – Operation

Portable Generator System