26

Owner’s Manual for Flameless Heat Cart

Troubleshooting

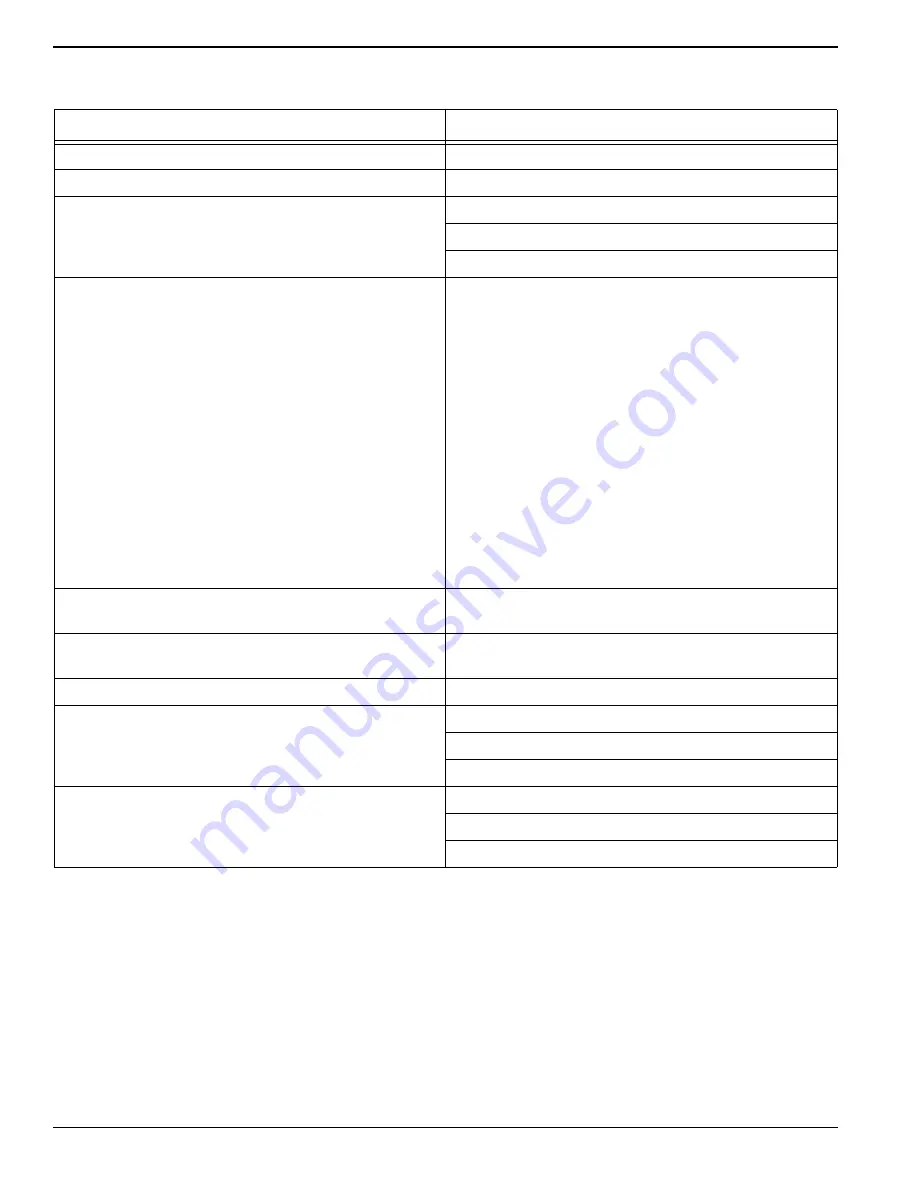

Digital Controller Status Messages

Message

Cause

Engine Warming — Please Wait

Engine coolant temperature < 140 °F (38 °C).

Engine Preheat

Wait approximately 10 seconds after heater powers up.

Engine is not ready — Check rpm, Fuel Level or Wait to

Start

Engine rpm < 500

Fuel level < 10%

Wait to Start signal

Low Fuel Warning

Fuel level < 20%

•

Fuel level notification appears on screen

•

Low Fuel Level beacon turns on

Fuel level

≤

16%

•

Fuel level notification appears on screen

•

Heat/fan load reduced to 50%

Fuel level

≤

12%

•

Fuel level notification appears on screen

•

Open heat circuit and close scroll fan circuit

•

Drop engine to idle

Fuel level

≤

8%

•

Fuel level notification appears on screen

•

Engine shuts down

Check heater settings or connections, then press Reset

on the Machine Overview

IFM controller detected a short or break in a sender.

Heater is cooling down — Please wait

IFM controller detects heater is in cool down. ON button

disabled.

Engine is going to shutdown

Fuel level

≤

8%

Engine fault shutdown

Low engine oil pressure

High engine coolant temperature

Engine overspeed

Heater shutdown due to temperature; pressure or level

out of range

High hydraulic temperature

Low hydraulic pressure

Low hydraulic level

Summary of Contents for MAC400HC

Page 4: ...iv Owner s Manual for Flameless Heat Cart This page intentionally left blank ...

Page 20: ...16 Owner s Manual for Flameless Heat Cart Operation This page intentionally left blank ...

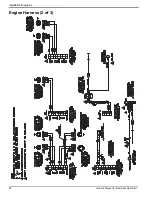

Page 32: ...28 Owner s Manual for Flameless Heat Cart Installation Diagrams Engine Harness 2 of 3 ...

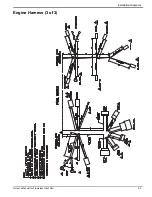

Page 33: ...Owner s Manual for Flameless Heat Cart 29 Installation Diagrams Engine Harness 3 of 3 ...

Page 39: ......