Summary of Contents for Magnum MLT6SC

Page 44: ...Maintenance 40 Owner s Manual for MLT6SC Light Tower This page intentionally left blank ...

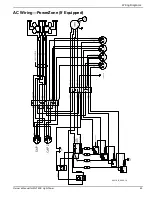

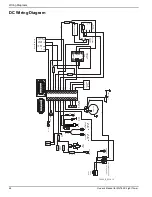

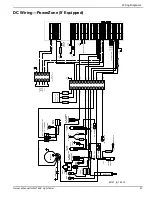

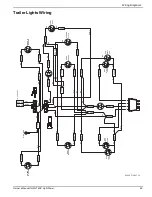

Page 48: ...Wiring Diagrams 44 Owner s Manual for MLT6SC Light Tower AC Wiring Diagram 90500_E_03 09 18 ...

Page 54: ...Wiring Diagrams 50 Owner s Manual for MLT6SC Light Tower This page intentionally left blank ...

Page 57: ...Service Log Owner s Manual for MLT6SC Light Tower 53 This page intentionally left blank ...

Page 58: ...Service Log 54 Owner s Manual for MLT6SC Light Tower This page intentionally left blank ...

Page 59: ......