Owner’s Manual for Mobile Light Tower

17

Operation

the factory. Contact Generac Mobile for additional

information before attempting to adjust the voltage

regulator.

Auxiliary Outlets

See

. Depending upon the model, the control

panel is equipped one or two 120V GFCI (A) and 240V

twist-lock (B) outlets for running accessories or tools from

the generator. Power is supplied to the receptacles any

time the engine is running and the main circuit breaker is

switched ON (I).

NOTE:

Do not pull more than 1000W from each outlet

when the lights are on. This will overload the generator

and cause the main circuit breaker to trip. Should the

breaker trip, switch off the lights, remove some of the

load to the outlets and wait 10 minutes for the bulbs to

cool before turning them back on.

With all of the lights off, the full generator output may be

used with the 240V twist-lock outlet.

Figure 3-8. Auxiliary Outlets

Wet Stacking

The unit is powered by a diesel engine. Diesel engines are

susceptible to wet stacking if lightly loaded. Wet stacking

occurs when an engine is run at less than 30% of its full

load capacity, causing unburned fuel to accumulate in the

exhaust system. Wet stacking can be detected by contin-

uous black exhaust when the unit is under a constant load.

It can also cause fouling of injectors and buildup on engine

valves. Diesel engines operate properly when applied

loads are between 30% and 100% capacity. Appropriate

generator sizing is determined by the anticipated load. If

the unit is in a wet stack condition, load the unit heavily for

five hours or until the exhaust is clear.

Engine Derating

All units are subject to derating for altitude and

temperature. Derating reduces the available power for

operating tools and accessories connected to the outlets.

For every increase in 1000 ft (305 m) of elevation, engine

performance for this unit typically drops between 2% and

4%. Also, engine performance decreases about 1% for

every 10ºF (5.6ºC) increase in ambient air temperature

over 72ºF (22ºC).

Shutting Down the Unit

Check with personnel using power supplied by the unit

and let them know the power is going to be turned off.

Make sure the power shutdown will not create any

hazards by accidentally turning off equipment that needs

to remain running (pumps, compressors, lights, etc.).

1.

Remove all loads from the outlets.

2.

See

. Switch the individual circuit

breakers for each light OFF (O).

3.

Switch the main circuit breaker OFF (O).

4.

Move the control power switch to STOP.

NOTE:

For extended storage time, disconnect the

battery. For extended storage requirements, refer to the

engine operator’s manual.

Figure 3-9. Shutting Down

Lowering the Mast

1.

Shut down the lights and engine. See

.

2.

If the trailer is going to be moved, it is

recommended that the mast is turned so the lights

face toward the back of the unit. To rotate the

mast:

a.

Loosen the mast rotation knob.

b.

Rotate the mast until the white arrows are

aligned and the metal stop tabs are touching.

The winch and lights should be facing toward

the back of the unit.

c.

Tighten the mast rotation knob.

3.

Press and hold the winch control toggle switch

downward to collapse the mast to its lowest

position. Verify the electrical cord does not get

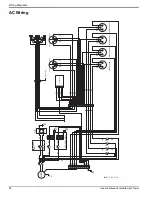

120V

240V

BREAKER

BREAKER

240V

BREAKER

NEUTRAL BONDED TO FRAME

I

O

004478

A

B

I

O

I

O

I

O

I

O

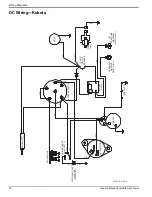

GLOW

PLUG

OFF

RUN

START

004550

(000278)

WARNING

Burn hazard. Lamps become extremely hot

while in use. Allow 10–15 minutes for cooling

before handling or lowering mast. Touching a

hot lens or fixture can cause severe burns.

Summary of Contents for MLT4060KV

Page 4: ...iv Owner s Manual for Mobile Light Tower Trailer Lights Wiring 33 ...

Page 24: ...20 Owner s Manual for Mobile Light Tower Operation This page intentionally left blank ...

Page 35: ...Owner s Manual for Mobile Light Tower 31 Wiring Diagrams DC Wiring Electric Winch ...

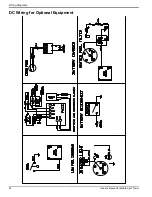

Page 36: ...32 Owner s Manual for Mobile Light Tower Wiring Diagrams DC Wiring for Optional Equipment ...

Page 38: ...34 Owner s Manual for Mobile Light Tower Wiring Diagrams This page intentionally left blank ...

Page 39: ......