Owner’s Manual

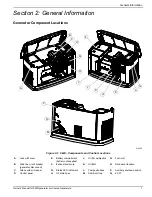

PWRgenerator™ Air-Cooled Generators

9 kW

SAVE THIS MANUAL FOR FUTURE REFERENCE

®

Register your Generac product at:

WWW.GENERAC.COM

1-888-GENERAC

(888-436-3722)

(000209b)

WARNING

Loss of life. This product is not intended to

be used in a critical life support application.

Failure to adhere to this warning could result

in death or serious injury.

Summary of Contents for PWRgenerator 9 kW

Page 39: ......