ELECTRICAL REQUIREMENTS

6

BEFORE CONNECTING THE MACHINE TO THE POWER SOURCE, VERIFY THAT THE VOLTAGE OF YOUR POWER

SUPPLY CORRESPONDS WITH THE VOLTAGE SPECIFIED ON THE MOTOR I.D. NAMEPLATE. A POWER SOURCE

WITH GREATER VOLTAGE THAN NEEDED CAN RESULT IN SERIOUS INJURY TO THE USER AS WELL AS DAMAGE

TO THE MACHINE. IF IN DOUBT, CONTACT A QUALIFIED ELECTRICIAN BEFORE CONNECTING TO THE POWER

SOURCE.

THIS TOOL IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR USE IN WET OR DAMP LOCATIONS.

GROUNDING INSTRUCTIONS

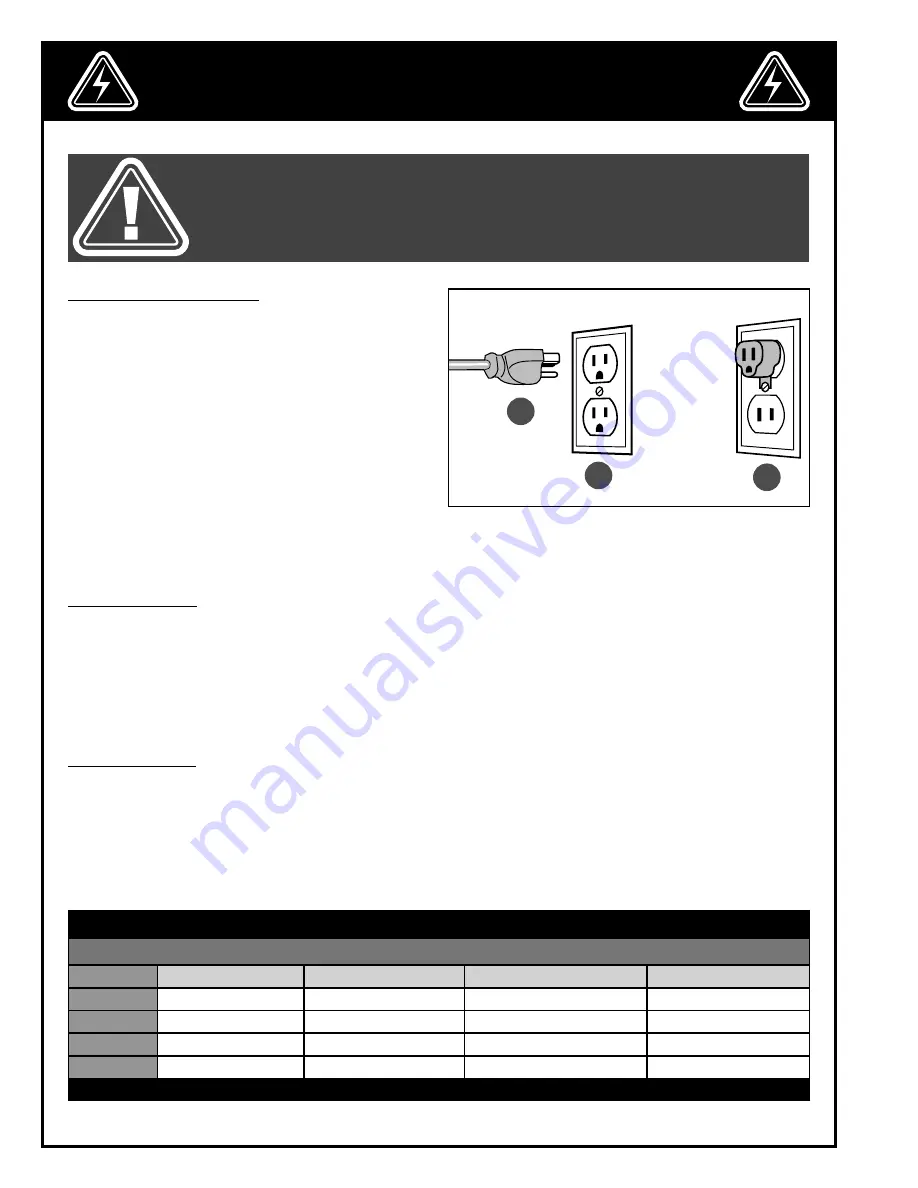

In the event of an electrical malfunction or short circuit,

grounding reduces the risk of electric shock. The motor

of this machine is wired for 120 V single phase opera-

tion and is equipped with a 3-conductor cord and

a 3-prong grounding plug

A

to fit a grounded type

receptacle

B

. Do not remove the 3rd prong (ground-

ing pin) to make it fit into an old 2-hole wall socket or

extension cord. If an adaptor plug is used

C

, it must be

attached to the metal screw of the receptacle.

Note: The use of an adaptor plug is illegal in some

areas. Check your local codes. If you have any

doubts or if the supplied plug does not correspond

to your electrical outlet, consult a qualified electri-

cian before proceeding.

CIRCUIT CAPACITY

Make sure that the wires in your circuit are capable of handling the amperage draw from your machine, as well

as any other machines that could be operating on the same circuit. If you are unsure, consult a qualified electri-

cian. If the circuit breaker trips or the fuse blows regularly, your machine may be operating on a circuit that is

close to its amperage draw capacity. However, if an unusual amperage draw does not exist and a power failure

still occurs, contact a qualified technician or our service department.

EXTENSION CORDS

If you find it necessary to use an extension cord with your machine, use only 3-wire extension cords that have

3-prong grounding plug and a matching 3-pole receptacle that accepts the tool’s plug. Repair or replace a dam-

aged extension cord or plug immediately.

Make sure the cord rating is suitable for the amperage listed on the motor I.D. plate. An undersized cord will cause

a drop in line voltage resulting in loss of power and overheating. The accompanying chart shows the correct size

extension cord to be used based on cord length and motor I.D. plate amp rating. If in doubt, use the next heavier

gauge. The smaller the number, the heavier the gauge.

TABLE - MINIMUM GAUGE FOR CORD

EXTENSION CORD LENGTH

AMPERES

50 feet

100 feet

200 feet

300 feet

< 5

18

16

16

14

6 to 10

18

16

14

12

10 to 12

16

16

14

12

12 to 16

14

12

*NR

*NR

*NR = Not Recommended

A

B

C