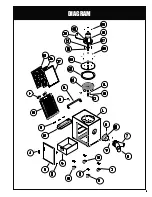

16

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PART #

DESCRIPTION

SPECIFICATION

QTY

10950-01

STEEL

CABINET

1

10950-02

HEX. FLANGE BOLT

5/16” X 3/8”

16

10950-03

SWIVEL

CASTER

3”

2

10950-04

DOOR

LATCH

3

10950-05

ACCESS

DOOR

1

10950-06

DUST

DRAWER

1

10950-07

“Y” FITTING DUST INLET

6” X 4” (X 2)

1

10088-08

INLET

CAP

4”

1

10950-09

CAP SCREW

5/16” X 1/2”

8

10950-10

INLET

MOUNT

6”

1

10950-11

PHILLIPS HEAD SCREW

3/16” X 1/4”

1

10950-12

DUST

TRAY

1

10950-13

FILTER

ACCESS

DOOR

1

10950-14

HANDLE

1

10950-15

1 MICRON FILTER (ITEM #10-953)

1

10950-16

ACTIVE CARBON FILTER (ITEM #10-952)

1

10950-17

STAINLESS STEEL FILTER (ITEM #10-951)

1

10950-18

ALUMINUM

IMPELLER

1

10950-19

CAP SCREW

M6 X 30

1

10950-20

IMPELLER

WASHER

1

10950-21

KEY

7 X 7 X 25

1

10950-22

FOAM

GASKET

1

10950-23

MOTOR

PLATE

1

10950-24

CAP SCREW

1/4” X 3/8”

8

10950-25

NUT

5/16”

4

10950-26

WASHER

5/16”

4

10950-27

HEX BOLT

5/16” X 1

4

10950-28

MOTOR

1

10950-29

GASKET

1

10950-30

SWITCH

1

10950-31

HINGE

5

10950-32

POWER

CORD

1

10950-33

LOCKABLE SWIVEL CASTER

2

NOTES

Summary of Contents for 10-950

Page 15: ...15 DIAGRAM ...

Page 17: ...17 NOTES ...