3.

Turn the lock screw clockwise to lock the tracking adjusment screw.

4.

Turn on the machine for 5-10 seconds to visually confirm the belt tracking.

5.

As needed, repeat this adjustment process until the belt is tracking evenly on the rollers.

15

1.

Insert the supplied 3 mm T-wrench

into the lock

screw

(through the hole in the front window

)

and turn counter-clockwise to unlock the tracking

adjustment screw

.

2.

Turn the tracking adjustment screw:

• Clockwise if the belt tracks to the right.

• Counter-clockwise if the belt tracks to the left.

Note: Turn the screw in 1/32 turn increments (approx.),

recheck and adjust again as needed.

VIEW THROUGH FRONT WINDOW

VIEW THROUGH FRONT WINDOW

ADJUSTING THE SANDING HEAD HEIGHT

The sanding head

can be raised or lowered

as

needed to suit the thickness of the workpiece.

NOTE: THE MINIMUM/MAXIMUM WORKPIECE THICK-

NESS CAPACITY IS 1/4” - 4”, AND THE MINIMUM WORK-

PIECE LENGTH CAPACITY IS 5”.

RIGHT SIDE VIEW

To adjust the sanding head height:

1.

Loosen the locking handle

located beside the

main motor to unlock the sanding head height

adjustment hand wheel.

2.

Put the workpiece on the conveyor belt and rotate

the hand wheel

:

• Clockwise to lower the sanding head.

• Counter-lockwise to raise the sanding head.

3.

Set the height of the sanding head so that the work-

piece

barely touches

the sanding belt

.

Note: The depth gauge

on front of the sander can be

used as a reference but it is not intended for high precision

measurements.

WORK PIECE

CONVEYOR BELT

* Effect exaggerated for clarity

UP

DOWN

RIGHT SIDE VIEW

DO NOT

Note: To avoid overworking the motor, creating a poten-

tial circuit overload, or damaging the sanding belt, do

not force the workpiece against or into the idler roller

4.

Tighten the locking handle

until snug to secure the sanding head height setting.

SANDING HEAD UNDERSIDE VIEW

TIGHTEN

LOOSEN

DO

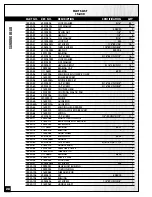

Summary of Contents for 15-030 M1

Page 23: ...23 UPPER ROLLER AND COVER ASSEMBLY ...

Page 25: ...25 CONVEYOR ...

Page 27: ...27 SANDING HEAD ...