CHANGING FEED SPEED

The conveyor speed ranges from 3 to 20 Feet Per

minute (FPM).

The feed speed adjustment knob is located above the

conveyor motor switch.

•

Turn the knob counter-clockwise

to decrease

the feed rate.

• Turn the knob clockwise

to increase the feed

rate.

As a general guideline, more aggressive sanding

using lower grits or sanding wider boards should be

done at slower speeds and sanding using higher grits or sanding narrow boards can be done at higher speeds.

Results can vary widely depending on a variety of factors. Experiment with feed speeds based on the workpiece

material, board width, depth of sanding, grit selection as well as required finish results.

DECREASE

SPEED

INCREASE

SPEED

RECOMMENDED ADJUSTMENTS

The two pressure rollers

(front and rear) maintain the

workpiece on the conveyor belt, preventing it from lifting

up from the conveyor into the sanding head

.

Both pressure rollers must be set 1 mm below the drive

roller (with sanding belt installed)

. If the pressure

rollers are even with or higher than the drive roller, there

is a high risk of workpiece kickback which could lead to

serious personal injuries.

The 2 pressure rollers are factory set to provide ade-

quate amount of downward pressure to the workpiece.

However, to prevent the risk of a kickback, it is highly re-

commended that you make sure that the pressure

rollers have not become misaligned during shipping

and that both ends of each pressure rollers are set 1 mm

below the contact roller, before using the sander for the

first time.

Due to vibration, over time, the height of the pressure

rollers may need to be re-adjusted. Periodically verify

the height of the pressure rollers when performing rou-

tine maintenance on your sander

.

ADJUSTING THE PRESSURE ROLLER HEIGHT

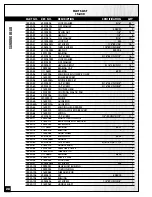

SANDING HEAD UNDERSIDE VIEW

ALWAYS MAKE SURE THAT THE PRESSURE ROLLERS ARE

SET 1 MM BELOW THE LOWER CONTACT ROLLER PRIOR

TO FIRST USE OF THIS SANDER.

16

DRIVE ROLLER WITH SANDING BELT INSTALLED

PRESSURE ROLLER

Summary of Contents for 15-030 M1

Page 23: ...23 UPPER ROLLER AND COVER ASSEMBLY ...

Page 25: ...25 CONVEYOR ...

Page 27: ...27 SANDING HEAD ...