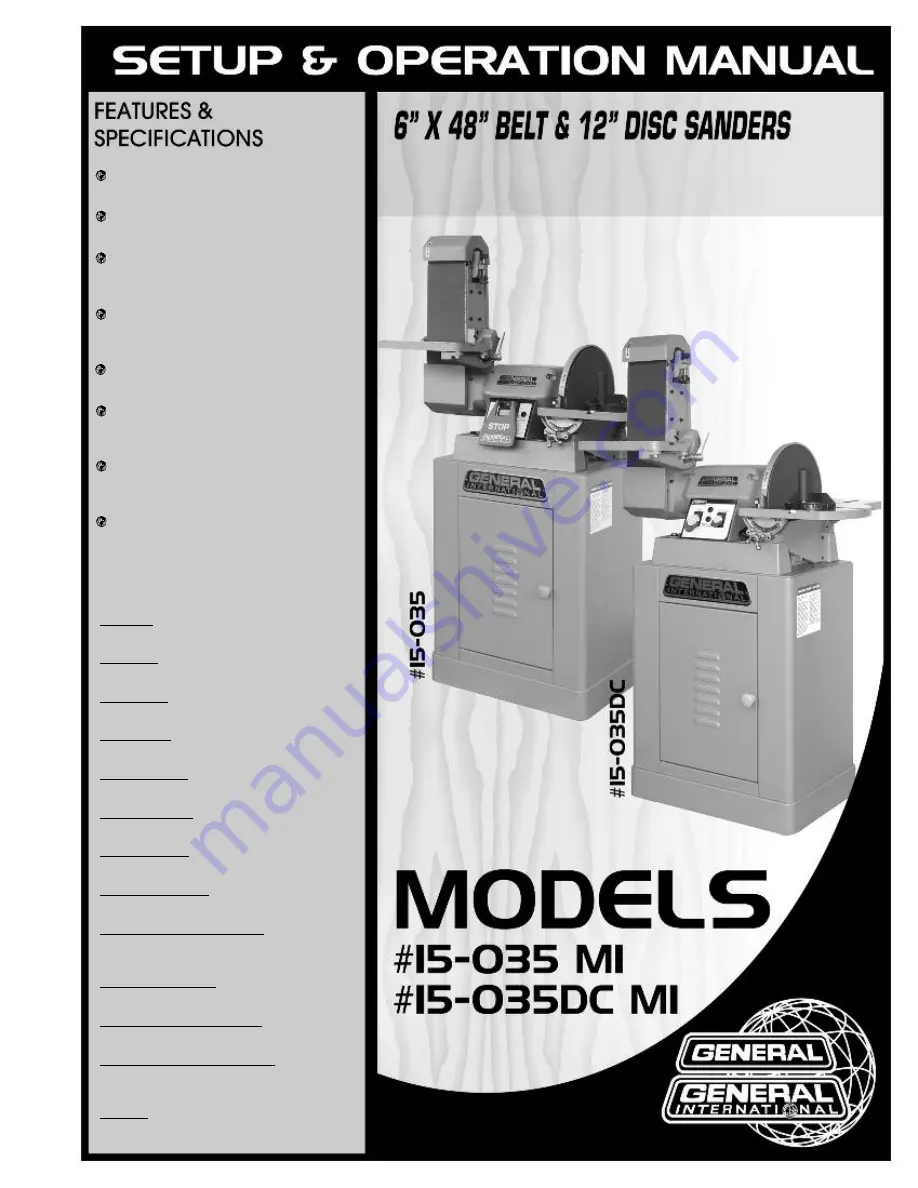

Combination 6” x 48” belt sander

and 12” disc sander.

Heavy-duty enclosed cabinet pro-

tects motor from sanding dust.

Two large surface, cast-iron, tilting

tables for unlimited sanding opera-

tions.

Sanding belt operates at any angle

from horizontal to vertical with posi-

tive stops at 90° and 45°.

Quick-change belt tension lever for

faster belt changes.

Handles all finishing operations

including: sanding, polishing, grind-

ing, surfacing and cleaning.

Safety switch with key, prevents unit

from being started when key is

removed.

Precision aluminum miter gauge

included.

BELT SIZE

6” X 48” (152 X 1220 MM)

DISC SIZE

12” (305 MM)

BELT SPEED

2250 LIN. FPM (686 LIN. MPM)

DISC SPEED

1750 RPM

BELT TABLE TILT

0 TO 45°

DISC TABLE TILT

45° OUT. & 10° IN.

BELT POSITION

HORIZONTAL / VERTICAL

DISC BACK PLATE

CAST IRON

DUST CHUTE OUTLET (BELT)

-

15-035 ONLY

4’’ (102 MM)

BASE DIMENSIONS

15 3/4” X 22” (400 X 559 MM)

MOTOR (PREWIRED 220V)

1 1⁄2 HP, 110 / 220 V, 13/6.5 A

MOTOR (DUST COLLECTOR)

-

15-035DC ONLY

1/4 HP, 110/220 V, 2A/1A

WEIGHT

365 LBS (166 KG)

VERSION 3 - REVISION 1 (APRIL 11/13)

S/N: 15-035 M1: 150296413 / 15-035DC M1: 150299413

© COPYRIGHT GENERAL INTERNATIONAL 04/2013

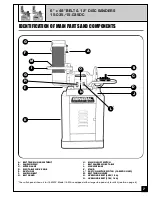

Built-in dust collector on model 15-035DC only.

Summary of Contents for 15-035 MI

Page 27: ...Notes 27...