15

You can also purchase them from your local tool, abrasives or sharpening supply dealer. You can find these

products in most areas. However, we recommend that you choose higher quality brand name belts. If the sanding

paper is too thick or too thin, or of inconsistent quality, it may not be properly gripped by the spring-loaded clamps.

Tip: Cleaning the sand paper with a belt dresser will extend the life of the sand paper. Consult your local distributor.

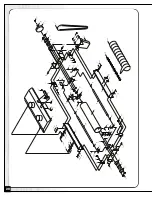

*MEASURED & CUT WITH ABRASIVE GRIT FACE SIDE DOWN

14 3/8”

111 5/8”

For users who prefer to purchase abrasives in longer uncut rolls or from bulk suppliers, the following cutting diagram

can be used to assist in cutting the bulk paper to the correct size for this sander.

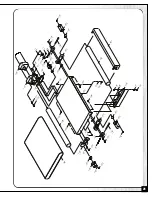

REMOVING THE SANDING BELT

Make sure the sander is disconnected from the

power source before removing/mounting the

sanding belt.

2.

Push the right spring-loaded clamp forward, , and remove the tab of the sanding belt from the slot at the right

end of the drum, .

3.

Unwind the sanding belt then push the left spring-loaded clamp forward and remove the tab of the sanding

belt from the slot of the left end of the drum.

1.

To access the sanding belt, unlock the drum cover

latch, , then lift up and tilt the cover towards the

rear, . The sanding belt is tightly winded around

the rotating drum and attached at both ends of the

drum by spring-loaded clamps, .