22

MAINTENANCE

CLEANING

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instruc-

tions given in this section. After using your machine, sweep up and discard any excess chips amd debris.

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORM-

ING ANY MAINTENANCE OR ADJUSTMENTS.

REGULAR MAINTENANCE TASK FREQUENCY

DAILY

WEEKLY

MONTHLY

2 x YEAR

• Basic cleaning of the

machine

• Fill the coolant tank if

necessary

• Inspect the blade

• Leave the saw head

in the “up” position to

reduce stress on the

return spring

• Check the splash

guards and verify

that the emergency

stop works properly

• Thoroughly clean the

machine thoroughly,

including the tank and

filter

• Clean and grease the

vise screw and the

slides

•

Clean the blade holder

• Make sure all the fast-

ners are tightened

• Inspect the condition of

all guards

• Grease the saw head

pivot shaft

• Change the gear box

oil

CHANGING THE GEAR BOX OIL

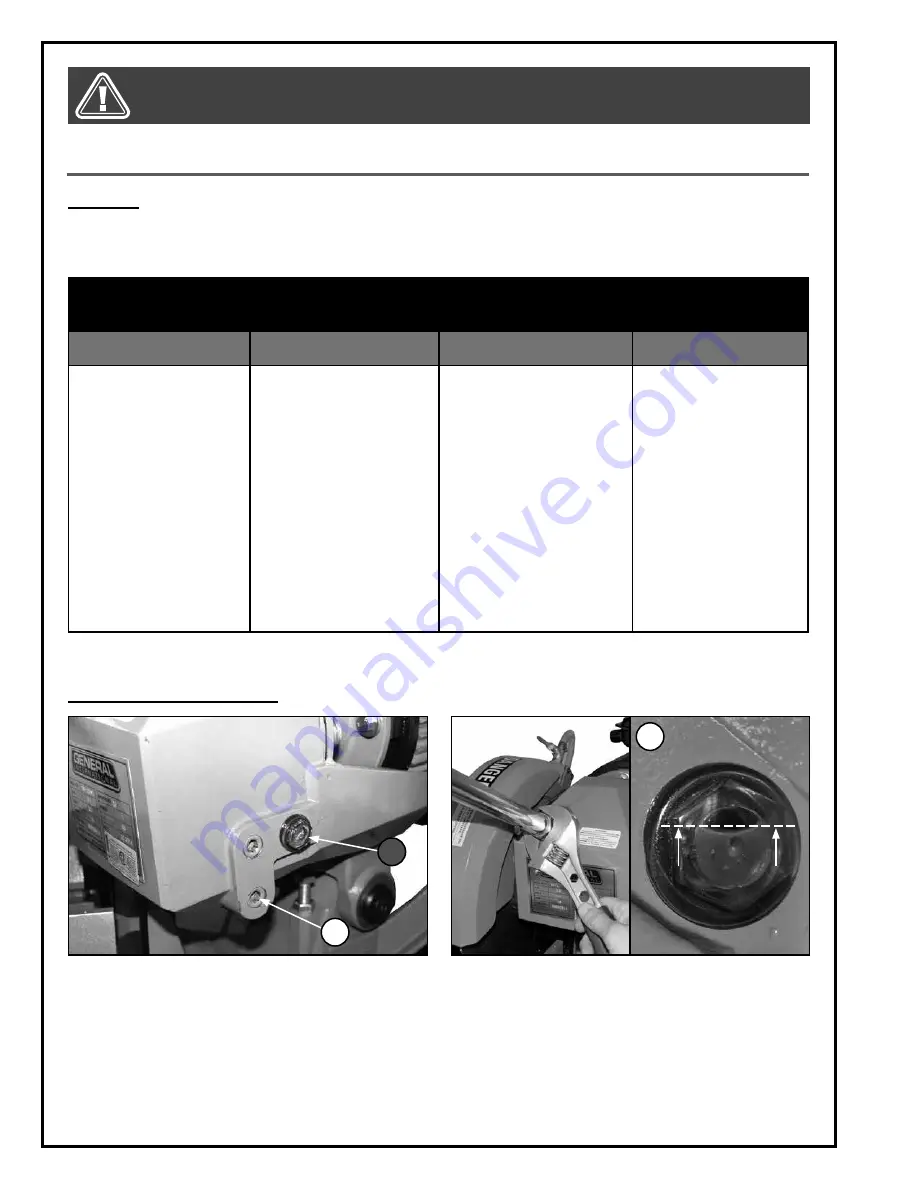

B

A

C

1

. Position the saw head in the down position. Re-

move oil plug

A

with a 10 mm Allen Key to drain

the gear box. Once the used oil is drained, re-install

the plug

A

.

2

. Raise the saw head to the up position. Loosen the

two jam nuts on the downfeed handle using a

wrench, then remove the downfeed handle to ac-

cess the filling hole.

3.

Fill the gear box with 0,25 liter of 460 grade gear oil.

The gauge

B

should be 3/4 full as shown

C.

When

the correct level is reached, re-install the downfeed

handle (see section “Installing the downfeed han-

dle”).