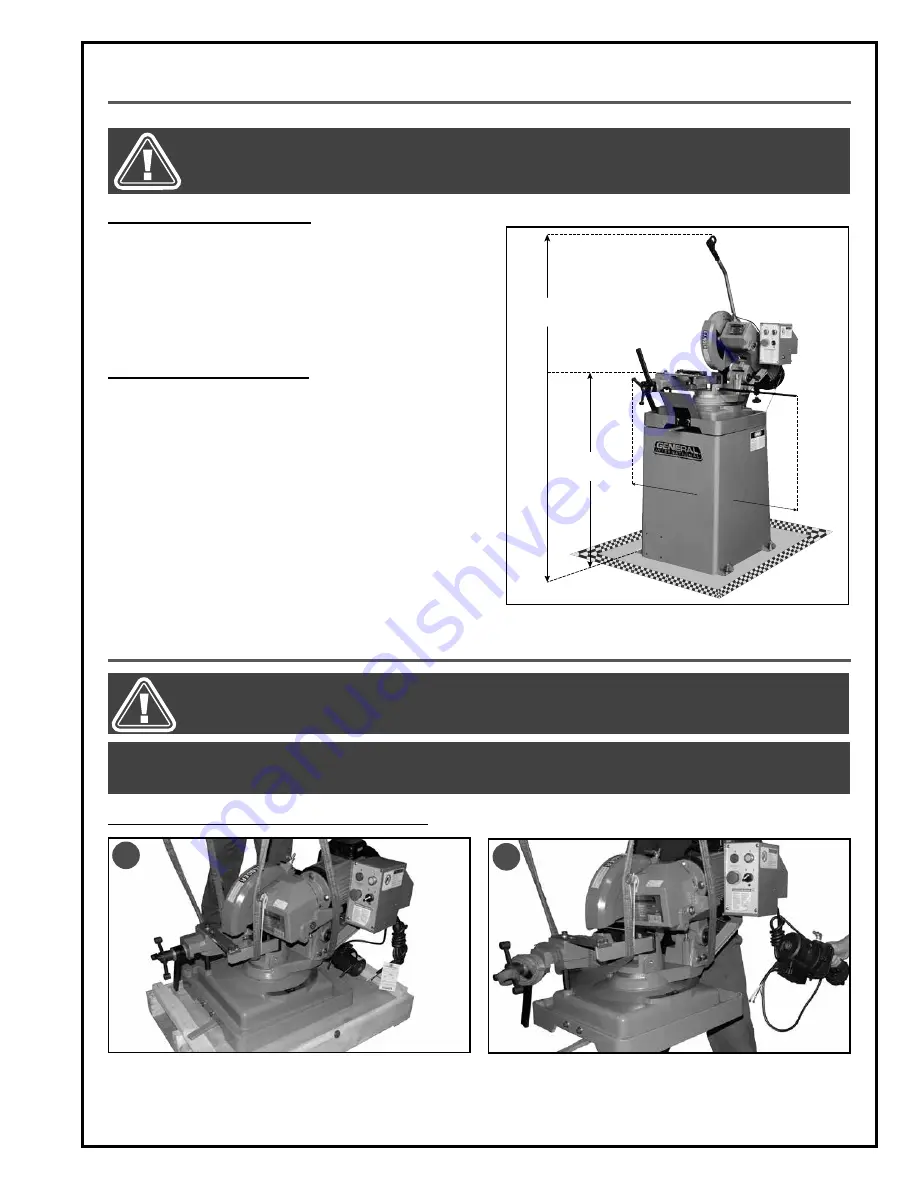

PLACEMENT WITHIN THE SHOP / SAFETY ZONE

THIS COLD CUT SAW MODEL 60-250 IS HEAVY. DO NOT OVER-EXERT. A HOIST OR FORKLIFT WITH STRAPS SHOULD BE

USED TO LIFT THIS MACHINE. TO LIMIT THE RISK OF SERIOUS INJURY OR DAMAGE TO THE MACHINE, ANY EQUIPMENT

USED TO LIFT THIS MACHINE SHOULD HAVE A RATED CAPACITY IN EXCESS OF 418 LBS (190 KG).

9

ASSEMBLY INSTRUCTIONS

INSTALLING THE MACHINE HEAD ON THE STAND

TIP: TO ASSEMBLE THIS UNIT, YOU WILL NEED TO LIFT THE HEAD OF THE MACHINE. DUE TO THE WEIGHT OF THE MACHINE, ADEQUATE

LIFTING EQUIPMENT SUCH AS A JACK, HOIST, OR FORKLIFT WITH STRAPS IS REQUIRED. ANY EQUIPMENT USED TO LIFT THE MA-

CHINE MUST HAVE A MINIMUM WEIGHT CAPACITY OF 418 LBS (190 KG).

BEFORE ASSEMBLING, MAKE SURE THAT THE SWITCH IS IN THE “OFF” POSITION AND THAT THE POWER CORD IS

UNPLUGGED. DO NOT PLUG IN OR TURN ON THE MACHINE UNTIL YOU HAVE COMPLETED THE ASSEMBLY AND

INSTALLATION STEPS DESCRIBED IN THIS SECTION OF THE MANUAL.

72"

40"

39"

PLACEMENT WITHIN THE SHOP

This machine should be installed and operated only on a

solid, flat and stable floor that is able to support the weight

of the machine (418 lbs - 190 kg) and the operator. Using

the dimensions shown as a guideline, plan for placement

within your shop that will allow the operator to work unen-

cumbered and unobstructed by foot traffic (either pass-

ing shop visitors or other shop workers) or other tools or

machinery.

ESTABLISHING A SAFETY ZONE

For shops with frequent visitors or multiple operators, it is

advisable to establish a safety zone around shop machin-

ery. A clearly defined “no-go” zone on the floor around

each machine can help avoid accidents that could

cause injury to either the operator or the shop visitor.

It is advisable to take a few moments to either paint (using

non-slip paint) or using tape, define on the floor the limits

or perimeter of each machines safety zone. Take steps to

ensure that all operators and shop visitors are aware that

these areas are off limits whenever a machine is running

for everyone but the individual operating the unit.

1.

Remove the bolts holding the machine head to the

shipping pallet and install appropriate lifting straps

around the head

A

.

Note: Verify the load capacity of the straps.

2.

Lift the machine head using appropriate lifting

equipment.

Note: Hold the pump to prevent damage to its power

cord B.

B

A