ENGLISH

3

141209

Warranty does not include failures, breakage or defects deemed after

inspection by General

®

International to have been directly or indirectly

caused by or resulting from; improper use, or lack of or improper

maintenance, misuse or abuse, negligence, accidents, damage in

handling or transport, or normal wear and tear of any generally considered

consumable parts or components.

Repairs made without the written consent of General

®

International will

void all warranty.

READ ALL INSTRUCTIONS

BEFORE OPERATING

SAVE THESE INSTRUCTIONS

Before attempting to operate your new tool, please read these instructions

thoroughly. You will need these instructions for the safety warnings,

precautions, assembly, operation, maintenance procedures, parts list and

diagrams. Keep your invoice with these instructions. Write the invoice

number on the inside of front cover. Keep the instructions and invoice in a

safe, dry place for future reference.

THE WARNINGS, CAUTIONS AND INSTRUCTIONS

discussed in this

instruction manual cannot cover all possible conditions or situations that

could occur. It must be understood by the operator that common sense

and caution are factors which cannot be built into this product, but must

be supplied by the operator.

IMPORTANT SAFETY

INSTRUCTIONS

The purpose of safety symbols is to attract your attention to possible

hazards. The safety symbols, and the explanations with them, deserve

your careful attention and understanding. The safety warnings do not, by

themselves, eliminate any danger. The instructions or warnings they give

are not substitutes for proper accident prevention measures.

DANGER!

Indicates an imminently hazardous situation which, if not

avoided, will result in serious injury or death.

WARNING!

Indicates an imminently hazardous situation which, if not

avoided, could result in serious injury or death.

CAUTION:

Indicates an imminently risky situation which, if not avoided,

could result in minor injuries or slight injury. It may also be used to notify

the user to remain alert regarding unsafe practises which may cause

property damage.

!

!

!

!

Summary of Contents for AC1106

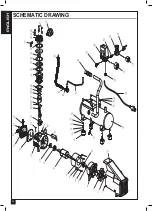

Page 12: ...ENGLISH 12 SCHEMATIC DRAWING...

Page 13: ......

Page 14: ......

Page 28: ...FRAN AIS 28 SCH MA...