ENGLISH

4

WARNINGS

1.

GROUND ALL TOOLS.

If the tool is equipped with three-pin plug, it should be plugged into a

three-pin electrical socket. Never remove the ground pin.

2.

AVOID BODY CONTACT WITH GROUNDED SURFACES

such as pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is grounded.

3.

TO REDUCE THE RISK OF ELECTRICAL SHOCK OR INJURY, DO

NOT EXPOSE TOOL TO MOISTURE.

Don’t use this tool in damp or wet locations. Keep out of rain.

4.

DO NOT ABUSE CORD.

Never use the cord to carry tools or pull the plug from an outlet. Keep

cord away from heat, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

5.

ALWAYS DISCONNECT THE TOOL FROM POWER SOURCE

before making any adjustments, storing, servicing, or changing

accessories. Such preventative safety measures reduce the risk of

starting the tool accidentally.

6.

KEEP AWAY FROM FLAMMABLES.

Do not attempt to operate this tool near flammable materials or

combustibles. Failure to comply may cause serious injury or death.

7.

RISK OF FIRE OR EXPLOSION.

Do not spray flammable liquid in a confined area. Spray area must

be well ventilated. Do not smoke while spraying or spray where spark

or flame is present. Keep compressors as far from spraying area as

possible.

CAUTIONS

1.

KNOW YOUR TOOL.

Read this manual carefully. Learn the tool’s applications and

limitations, as well as specific potential hazards peculiar to it.

2.

REMOVE ADJUSTING KEYS OR WRENCHES BEFORE TURNING

THE TOOL ON.

A wrench or key that is left attached to a moving part of the tool may

result in personal injury.

3.

KEEP WORK AREA CLEAN AND WELL LIT.

Cluttered or dark work areas invite accidents.

4.

KEEP CHILDREN AWAY.

All children should be kept away from the work area. Never let a child

handle a tool without strict adult supervision.

5.

DO NOT OPERATE THIS TOOL IF UNDER THE INFLUENCE OF

ALCOHOL OR DRUGS.

Read warning labels on prescriptions to determine if your judgment or

reflexes are impaired while taking drugs. If there is any doubt, do not

attempt to operate.

6.

USE SAFETY EQUIPMENT.

Eye protection should be worn at all times when operating this tool.

Use ANSI approved safety glasses. Everyday eyeglasses are NOT

safety glasses. Dust mask, non-skid safety shoes, hard hat, or hearing

protection should be used in appropriate conditions.

7.

WEAR PROPER APPAREL.

Loose clothing, gloves, neckties, rings, bracelets, or other jewelry may

present a potential hazard when operating this tool. Please keep all

apparel clear of the tool.

8.

DON’T OVERREACH.

Keep proper footing and balance at all times when operating this tool.

9.

DO NOT FORCE TOOL.

Use the correct tool for your application. The correct tool will do the job

better and safer at the rate for which it was designed.

10.

DO NOT USE THE TOOL IF THE SWITCH DOES NOT TURN IT ON

AND OFF.

Any tool that cannot be controlled with the switch is dangerous and

must be repaired.

!

!

Summary of Contents for AC1106

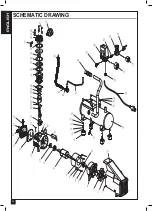

Page 12: ...ENGLISH 12 SCHEMATIC DRAWING...

Page 13: ......

Page 14: ......

Page 28: ...FRAN AIS 28 SCH MA...