ENGLISH

8

NOTE:

DO NOT over tighten Air Regulator or Air Chuck.

INSTALLING THE AIR FILTER

The metal Air Filter is installed into the threaded port of the cylinder head.

1. Thread the Air Filter into the Cylinder Head by turning the Air Filter

clockwise.

2. Securely tighten the Air Filter in place with a wrench.

NOTE:

DO NOT over tighten Air Filter.

OPERATION

BEFORE OPERATING YOUR NEW AIR COMPRESSOR

please check the following points carefully:

1. Check that all nuts and bolts are secure.

2. Make sure oil has been properly added to compressor. (See Installing

Oil and Oil Breather Cap section.)

INITIAL START-UP PROCEDURE

1. Open the Air Tank Drain Valve to permit air to escape, preventing air

pressure buildup in the air tank.

2. Run the compressor for a minimum of 20 minutes in this “no-load”

position to lubricate the piston and bearings.

3. Close Air Tank Drain Valve. Your compressor is ready for use.

Depending on the CFM draw of the tools being operated, your new Air

Compressor can be used for operating paint sprayers, air tools, grease

guns, airbrushes, caulking guns, abrasive blasters, tire & plastic toy

inflation, spraying weed killer and insecticides, etc. Proper adjustment of

the Air Pressure Regulator is necessary for all of these operations. Refer

to the air pressure specifications provided with the tool you are using.

GENERAL OVERVIEW

To compress air, the piston moves up and down in the cylinder. On the

down stroke air is drawn in through the valve inlet. The discharge valve

remains closed. On the upstroke of the piston air is compressed. The inlet

valve closes and air is forced out through the discharge valve, through

the check valve, and into the air tank. Working air is not available until

the compressor has raised the tank pressure above that required at the

air service connection. The air inlet filter openings must be kept clear of

obstructions, which could reduce air delivery of the compressor.

INSTALLATION AND LOCATION

Locate the compressor in a clean, dry and well ventilated area. The

compressor should be located 12 to 18 inches from walls or any other

obstruction which would interfere with airflow. Compressor should be

located in a temperature controlled area between 32° and 95° fahrenheit.

Place the compressor on a firm, level surface. The compressor is designed

with heat dissipation fins which allow for proper cooling. Keep the fins (and

all other parts which collect dust or dirt) clean. A clean compressor runs

cooler and provides longer service. Do not place rags, containers or other

material on top of the compressor.

CONNECTING TO POWER SOURCE

This air compressor is designed to operate on a properly grounded 120

volt, 60Hz, single phase, alternating current (ac) power source with a

fused 20 amp time delayed fuse or circuit breaker. It is recommended that

a qualified electrician verify the ACTUAL VOLTAGE at the receptacle into

which the unit will be plugged and confirm that the receptacle is properly

fused and grounded. The use of the proper circuit size can eliminate

nuisance circuit breaker tripping while operating your air compressor.

Summary of Contents for AC1106

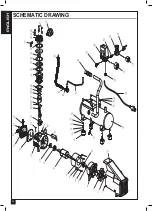

Page 12: ...ENGLISH 12 SCHEMATIC DRAWING...

Page 13: ......

Page 14: ......

Page 28: ...FRAN AIS 28 SCH MA...